Device and arrangement system for adjusting bearing clearance

A technology of bearing clearance and rolling bearing, applied in axle suspension devices, bearings, ball bearings, etc., can solve the problems of time-consuming and complex adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

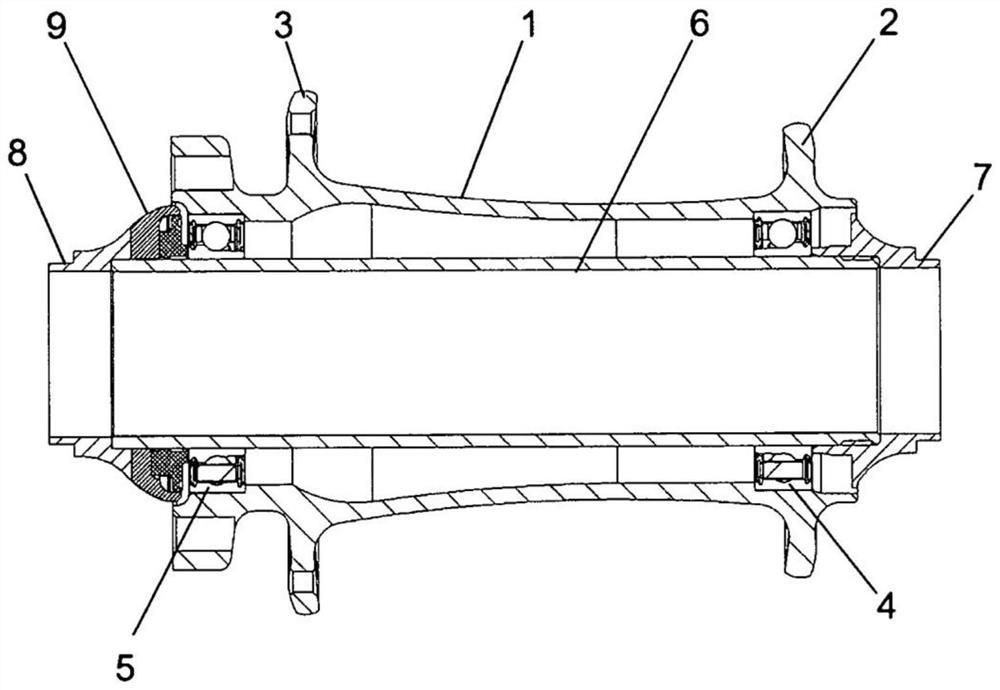

[0023] figure 1 The front hub of a bicycle is shown, which comprises a hub body 1 with spoke flanges 2, 3 on the right and left as viewed in the direction of travel and a spoke flange supported in the hub body 1 by right and left ball bearings 4, 5. Hollow shaft6. The outer ring of the ball bearing 4 is pressed into the hub body 1 in the area of the right spoke flange 2, and the outer ring of the left ball bearing 5 is pressed into the hub body 1 in the area protruding axially from the left spoke flange 3. The hollow shaft 6 is in turn connected with the inner ring of each ball bearing 4, 5 by a sliding fit. The hollow shaft 6 is provided with end caps 7, 8 on both sides, wherein the right end cap 7 is screwed onto the hollow shaft 6, and between the left end cap 8 and the left ball bearing 5, the bearing clearance adjusting mechanism according to the present invention is used. Device 9 sleeves are inserted on the hollow shaft 6.

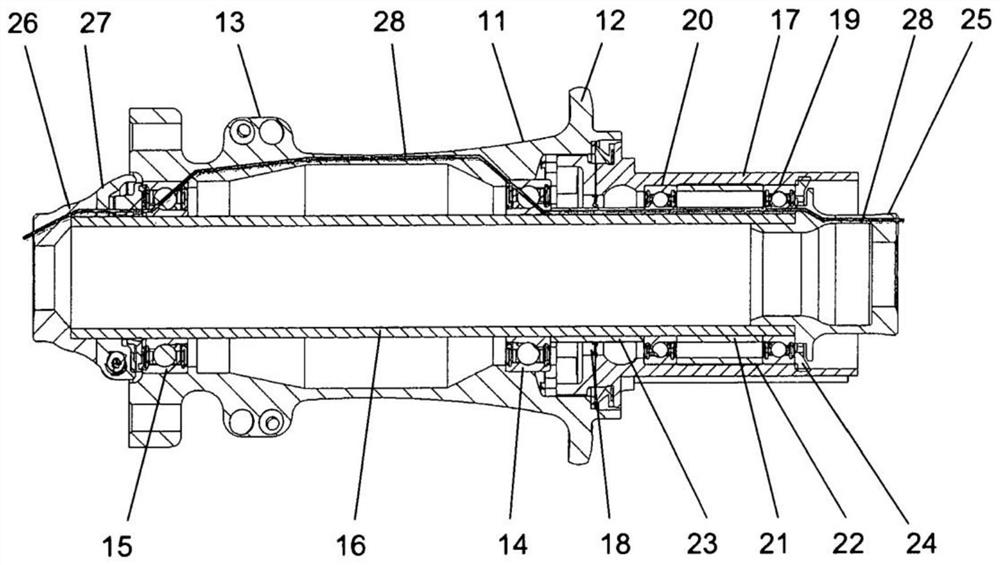

[0024] figure 2 The rear hub of a bicy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com