Evaporative load tank for aircraft testing

An evaporative, aircraft technology, applied in the field of aviation flight test, can solve problems such as affecting the normal work of test pilots and the inability to dissipate heat, and achieve the effect of preventing scalding test personnel and ensuring the safety of test flight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

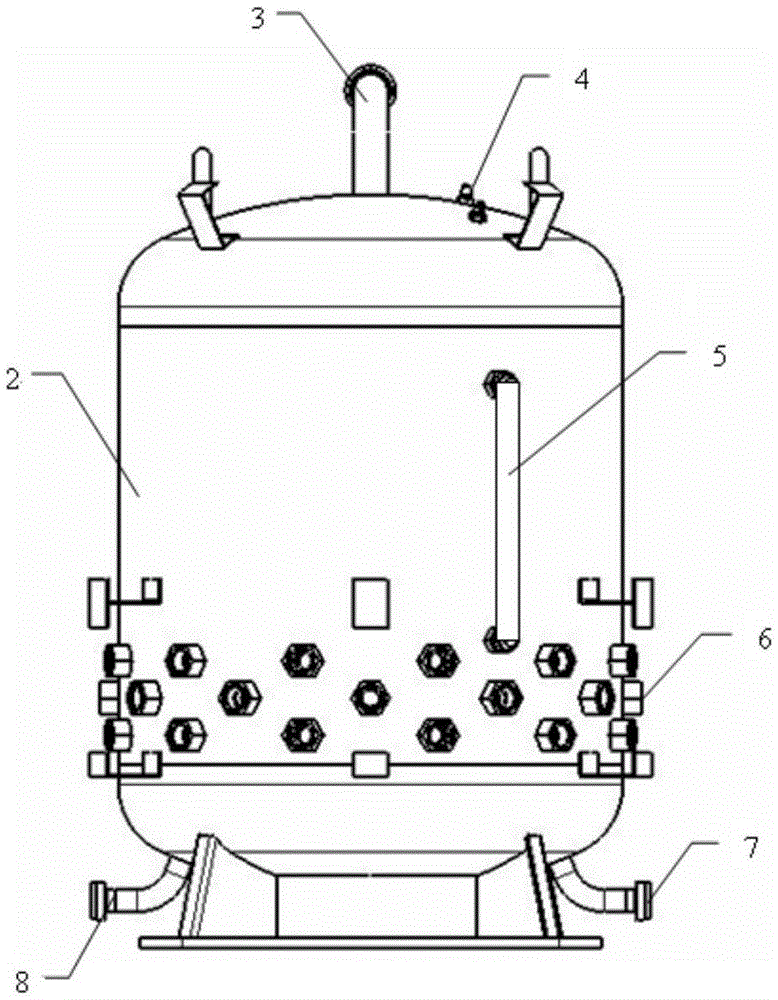

[0009] The invention will be described in further detail below. see figure 1 , the evaporative load tank used for aircraft of the present invention is a vertical load tank, comprising a tank body heat insulation protection cover 1, a pressure vessel tank 2, a discharge interface 3, an overtemperature and overpressure sensor 4, a liquid level gauge 5, Load unit 6 , liquid discharge interface 7 , infusion interface 8 . The pressure vessel tank 2 is made of stainless steel, and welded according to the boiler pressure vessel design specification. The tank tank has a discharge port 3, an infusion port 8, a liquid discharge port 7, a liquid level gauge 5, and an overtemperature and overpressure sensor 4. The pressure vessel tank 2 has a strength It can bear the overload of 9g forward and 6g downward to ensure the safe storage of the liquid in the evaporative load tank; the heat insulation protection cover 1 of the tank body is protected by ultra-fine glass wool heat insulation bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com