Material special for plastic pipes and preparation method of continuous-fiber-cloth-enhanced plastic pipe

A technology of plastic pipes and continuous fibers, which is applied in the field of preparation of special materials for plastic pipes and continuous fiber cloth reinforced plastic pipes, can solve the problems that the tensile strength, impact resistance strength, and strength and toughness of plastic pipes cannot be effectively improved, etc., Achieve the effects of inhibiting creep and stress relaxation damage, long service life and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

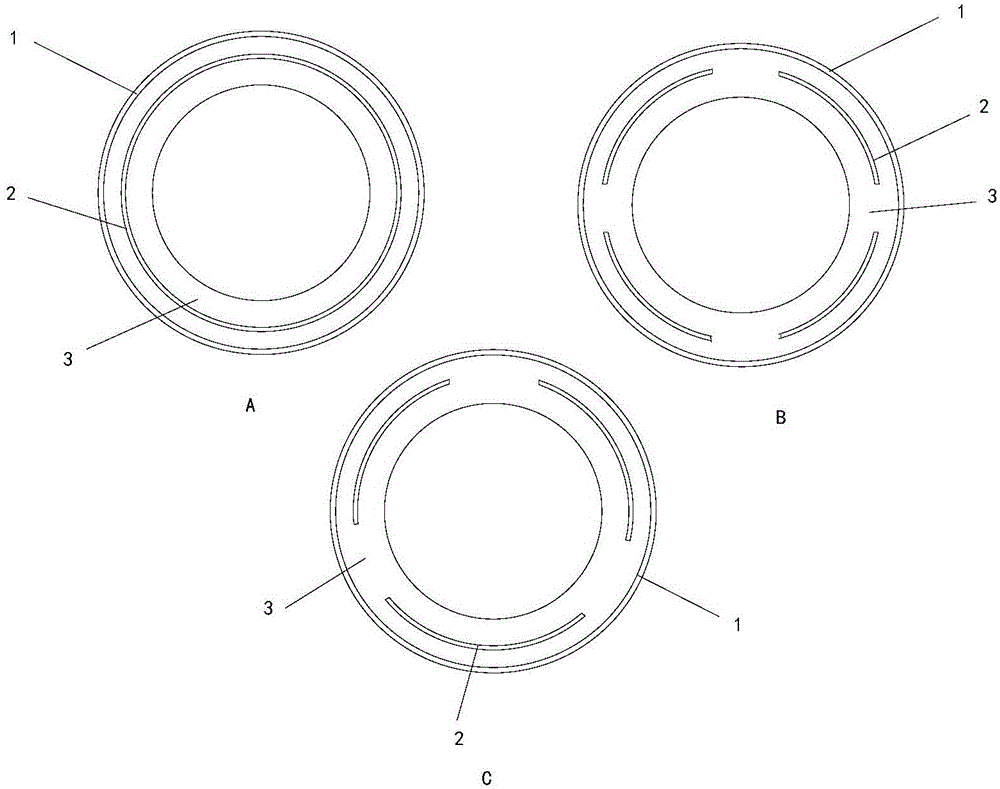

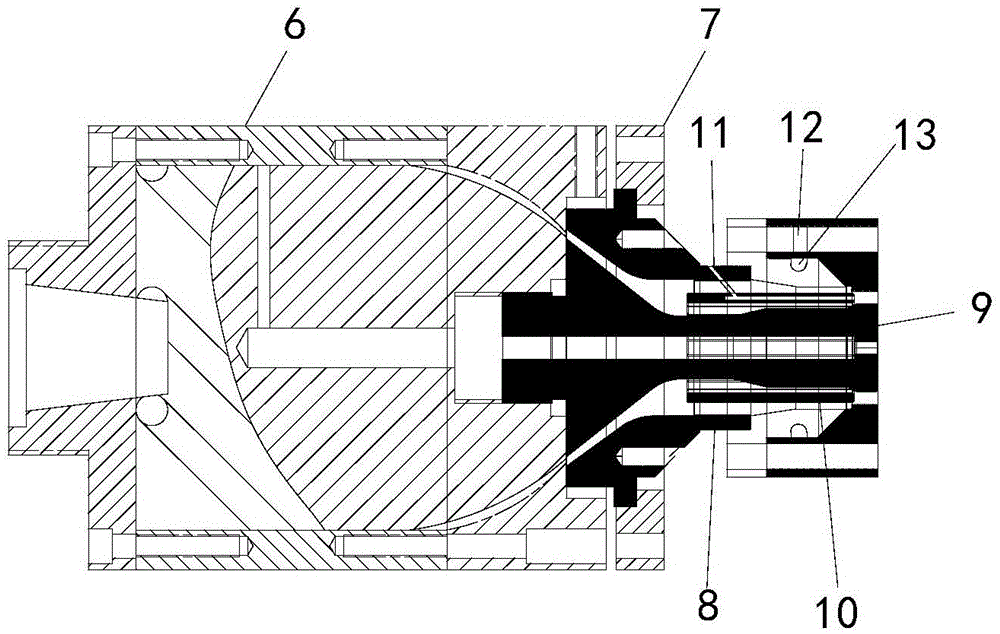

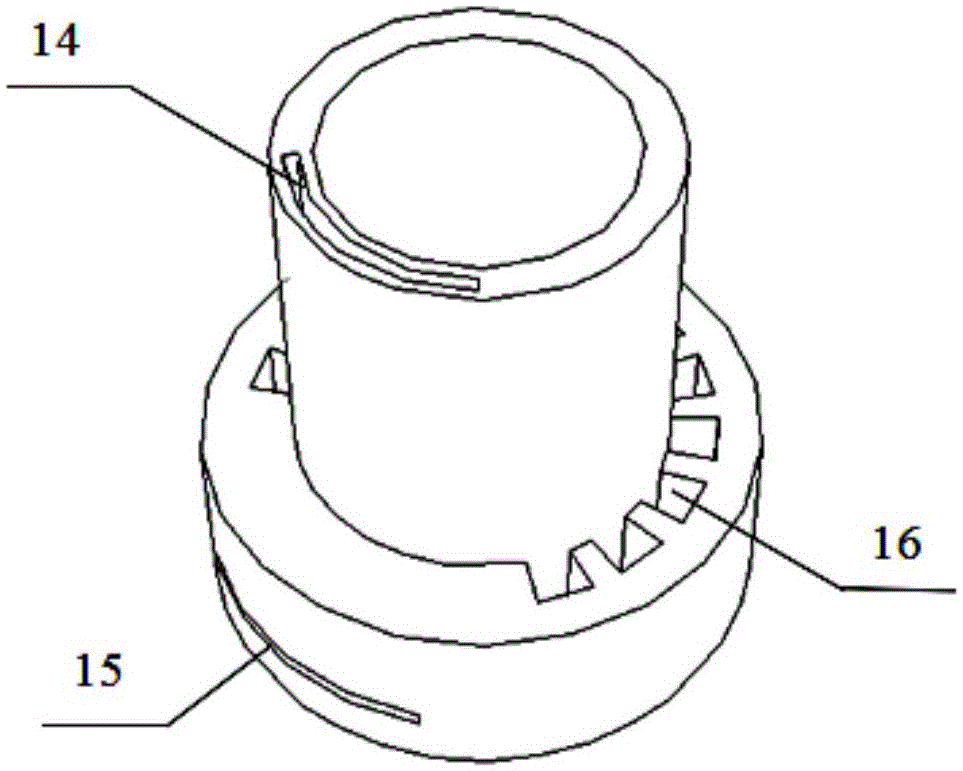

Method used

Image

Examples

Embodiment 1

[0041] Plastic pipe special material ingredients:

[0042] HDPE resin: 100 kg;

[0043] POE: 3kg;

[0044] EVA: 3 kg;

[0045] Silane coupling agent: 2 kg;

[0046] Polyethylene wax: 0.3 kg;

[0047] Zinc stearate: 0.3 kg;

[0048] Antioxidant 168: 0.1 kg;

[0049] Nucleating agent: 0.1 kg.

[0050] Firstly, pre-coat PE resin on a continuous fiber cloth with a certain warp and weft density, and reserve it; HDPE, POE, EVA, silane coupling agent, polyethylene wax, zinc stearate, antioxidant 168, and nucleating agent are prepared according to the above The ratio is added to the high-speed mixing mixer in turn and mixed evenly to obtain special pipe materials; the special materials enter the main extruder and auxiliary extruder respectively, and meet with the continuous fiber cloth passing through the die at the mouth of the die. Calibrate, cool, form, and finally obtain continuous fiber cloth reinforced plastic pipes.

Embodiment 2

[0052]Plastic pipe special material ingredients:

[0053] PP resin: 100 kg;

[0054] Inorganic powder: 30 kg;

[0055] EVA: 2 kg;

[0056] EPDM: 2 kg;

[0057] Aluminate coupling agent: 2 kg;

[0058] Paraffin: 1 kg;

[0059] Zinc stearate: 0.2 kg;

[0060] Antioxidant BHT: 0.1 kg;

[0061] Nucleating agent: 0.1 kg.

[0062] First, the continuous fiber cloth with a certain warp and weft density is pre-coated with PE resin, and it is used for later use; PP, inorganic powder, EVA, EPDM, aluminate coupling agent, paraffin, zinc stearate, antioxidant BHT, The nucleating agent is added into the high-speed mixing mixer in sequence according to the above ratio and mixed evenly to obtain special pipe material; the special material enters the main extruder and auxiliary extruder respectively, and is mixed with the continuous fiber cloth passing through the die at the die port. Intersect with each other, after vacuum sizing, cooling and forming, the continuous fiber cloth reinfo...

Embodiment 3

[0064] Plastic pipe special material ingredients:

[0065] HDPE resin: 100 kg;

[0066] Inorganic powder: 60 kg;

[0067] EVA: 2 kg;

[0068] POE: 2kg;

[0069] Ethylene-octene copolymer: 1 kg;

[0070] Titanate coupling agent: 2 kg;

[0071] Paraffin: 0.5 kg;

[0072] Polyethylene wax: 0.2 kg;

[0073] Antioxidant 1010: 0.1 kg;

[0074] Nucleating agent: 0.1 kg.

[0075] Firstly, pre-coat PE resin on a continuous fiber cloth with a certain warp and weft density, and reserve it; HDPE, inorganic powder, EVA, POE, ethylene-octene copolymer, titanate coupling agent, paraffin wax, polyethylene wax , Antioxidant 1010, and nucleating agent are sequentially added to the high-speed mixing mixer according to the above ratio and mixed evenly to obtain special pipe materials; The cloth meets each other at the mouth of the die, and after vacuum sizing, cooling and forming, the continuous fiber cloth reinforced plastic pipe is finally obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap