Color wheel assembly and projection device

A color wheel and component technology, applied in projection devices, optics, instruments, etc., can solve the problems of high working noise and low heat dissipation efficiency of color wheels, achieve good noise reduction, shorten heat conduction path, and increase heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

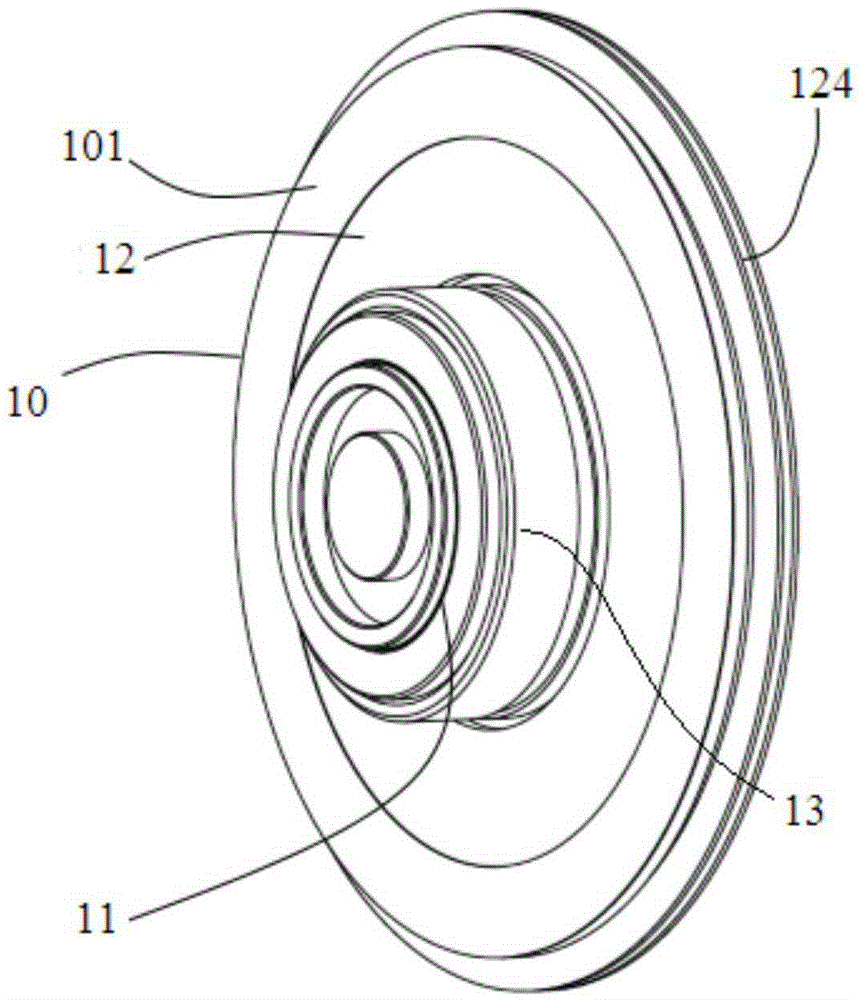

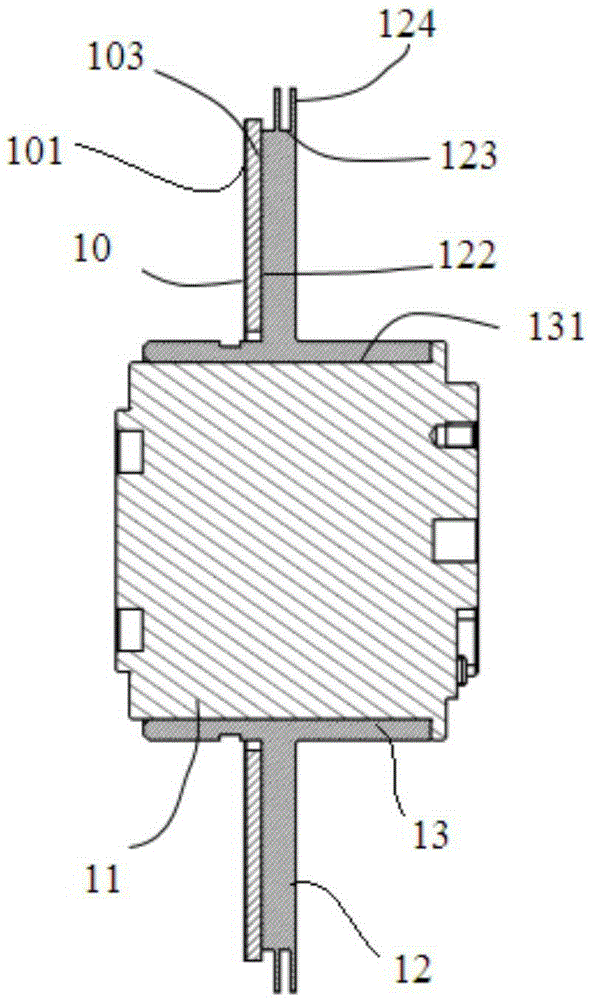

[0024] The color wheel assembly provided in this embodiment, such as figure 1 As shown, it includes a color wheel 10, a color wheel substrate 12, and a driving device for driving the color wheel substrate 12 to rotate. The color wheel 10 and the color wheel substrate 12 are both disc-shaped, and the driving device is a motor 11. A heat sink 124 is provided on the outer edge of the color wheel substrate 12, and the heat sink 124 protrudes from the side surface 123 of the color wheel substrate 12. The diameter of the outer circle of the color wheel substrate 12 matches (that is, the same or similar) to the outer diameter of the fluorescent area 101 of the color wheel, and the fluorescent area 101 of the color wheel 10 is arranged on the outer edge of the color wheel 10 in an annular band. The fluorescent area 101 is the heating area of the color wheel 10. The heat sink 124 is arranged on the outer edge of the color wheel substrate 12, so that the heat transfer path from the pho...

Embodiment 2

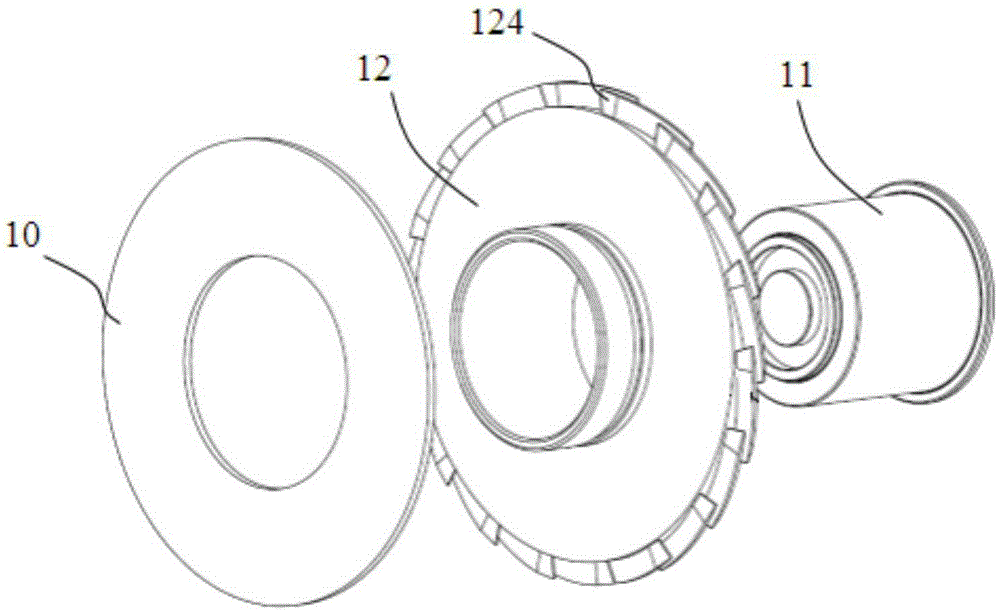

[0033] The color wheel assembly given in this embodiment is improved on the basis of the first embodiment, such as image 3 As shown, in this embodiment, the heat sink 124 is arranged at an oblique angle on the side surface 123 of the color wheel substrate 12, and the two ends of the heat sink 124 are respectively flush with the two axial end surfaces of the color wheel substrate 12. The surface of 124 and the axial direction of the color wheel substrate 12 form a specific included angle, that is, the heat sink 124 is inclined at a certain angle with respect to the axial end surface of the color wheel substrate 12. In other words, each individual heat sink 124 starts from the outer edge of one end surface of the color wheel substrate 12 in the axial direction, and extends along the side surface 123 of the color wheel substrate 12 to the other end surface of the color wheel substrate 12 in the axial direction. It is similar to the multi-vortex fan structure provided on the side s...

Embodiment 3

[0036] The color wheel assembly given in this embodiment is an improvement of the previous embodiment, such as Figure 4 As shown, the heat sink 124 in this embodiment has an airfoil structure, that is, the cross section of the heat sink 124 along the circumferential direction of the color wheel substrate 12 is roughly in the shape of a droplet with one thick end and thin end, and the overall heat sink 124 resembles an airplane wing. . The relatively thick end of the heat sink 124 faces an axial end surface of the color wheel substrate 12 and is located at the windward end of the axial airflow generated by the heat sink 124 when the color wheel substrate 12 rotates; The end of the heat sink 124 with a relatively thin thickness is tapered to extend toward the two axial ends of the color wheel substrate 12 and is located at the wake end of the axial air flow, that is, the end with a larger thickness of the airfoil structure is provided At the windward end of the heat sink 124, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com