Fast-acting high-current controlled fuse

A high current, fuse technology, applied in the direction of circuits, electrical components, emergency protection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

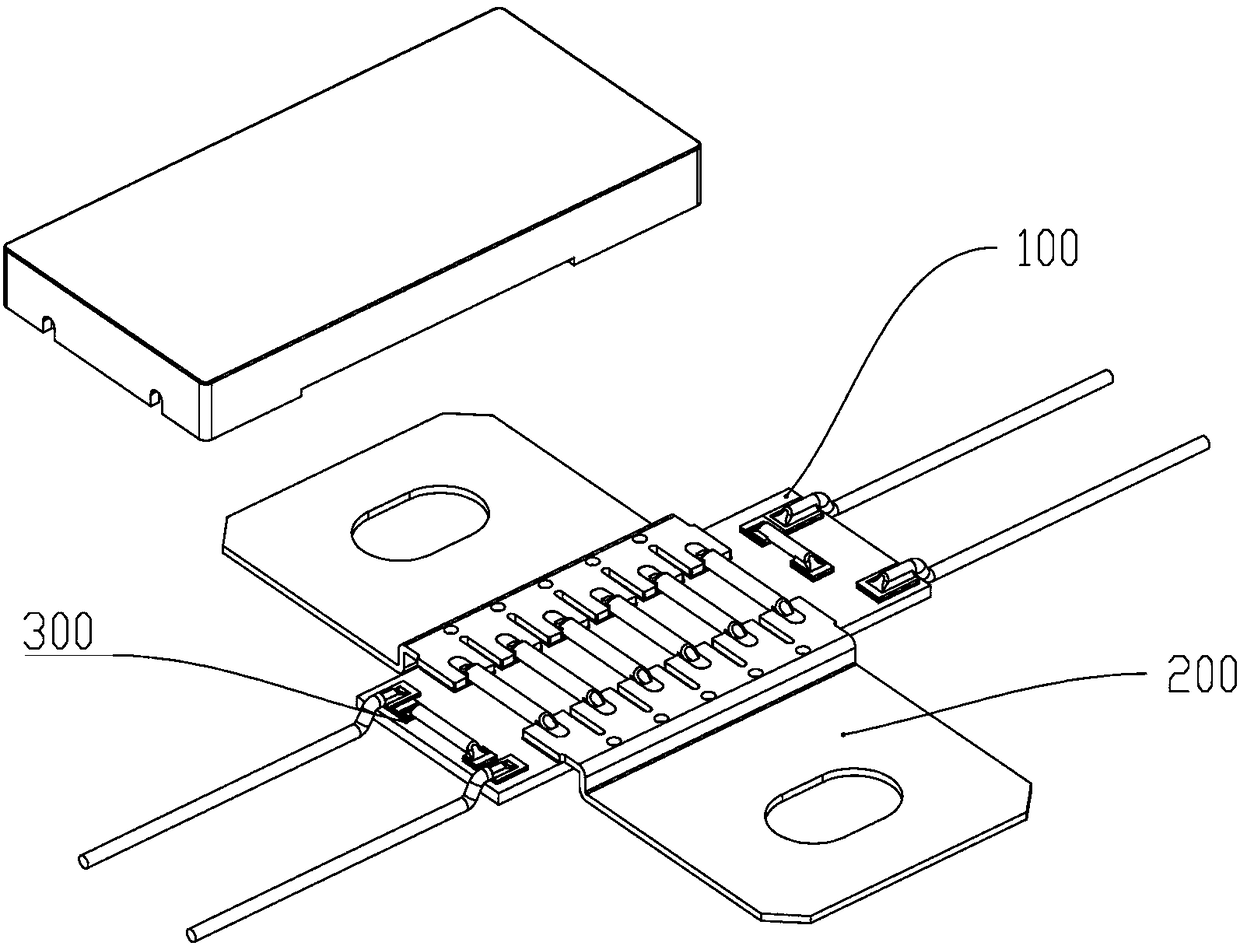

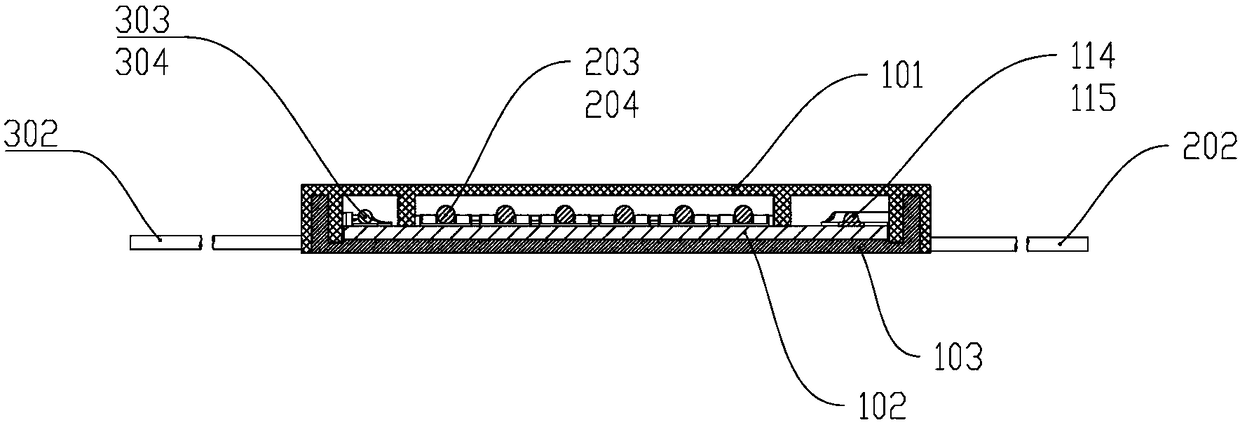

[0061]The fast-acting high-current controlled fuse of the present invention includes a heating device 100 and a current-through device 200 . The flow-through device 200 includes two sheet-shaped left electrode pins 201 and right electrode pins 202 separated from each other, and one or more first fuses connected between the two pieces of electrode pins. The left electrode pin 201 and the right electrode pin 202 are provided with grooves, parallel to the heating device 100 , and both include a stepped portion, and the lower edge of the stepped portion is flush with the lower edge of the heating device 100 .

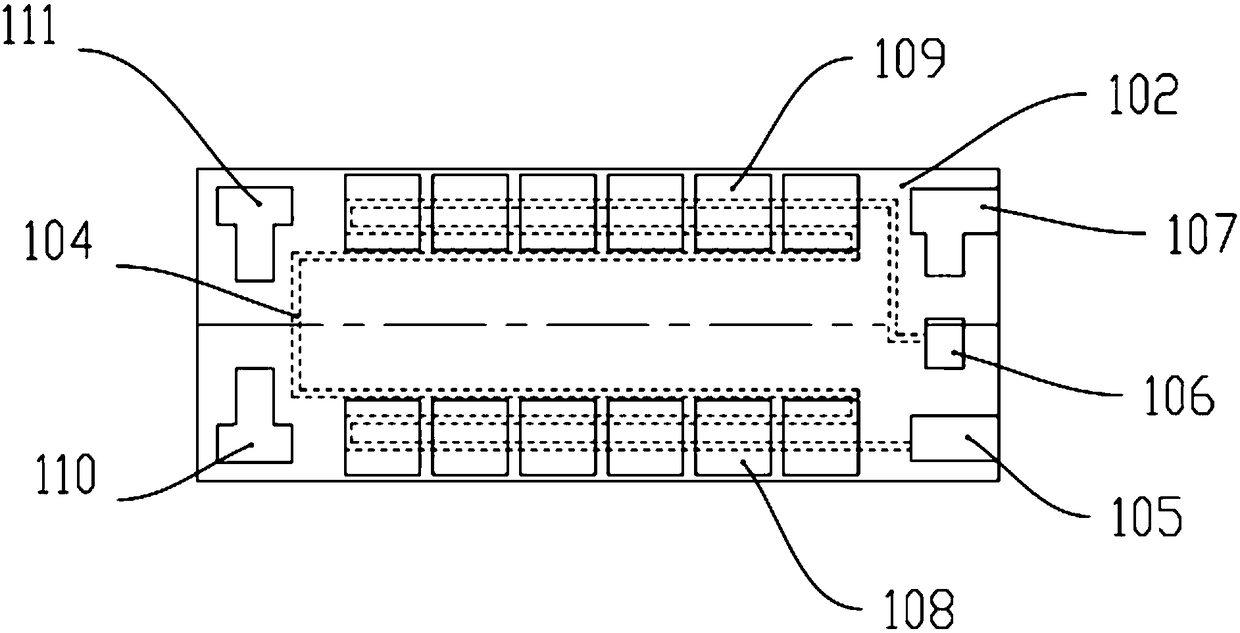

[0062] Such as image 3 As shown, the two ends of the heating device 100 close to the surface of the flow-through device 200 are respectively provided with a left flow-through pad 108 and a right flow-through pad 109, and the left electrode pin 201 includes a left groove 2011, which is welded on the left flow-through pad 109. On the pad 108, an independent welding point is...

Embodiment 2

[0069] In the present invention, the second fusing device may not be provided. At this time, the third operating temperature of the third fusing device only needs to be higher than the first operating temperature, so that after the first fusing device is fused, the third fusing device continues to be heated until the temperature reaches the third temperature. Action temperature, the third fusing device is fused, thereby sending out a remote signaling signal, informing the system that the cut-off function has been executed.

Embodiment 3

[0071] The flow-through device 200 can also be connected with a high breaking device in parallel to improve the breaking capacity. The high-breaking device can be a fusible alloy that is greatly affected by temperature, or a current fuse that is greatly affected by current. When it is a fusible alloy, the fusible alloy whose action temperature is higher than the first action temperature, when it is a current fuse, its internal resistance is greater than the internal resistance of the first fusing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com