Biologically fermented feed and preparation method thereof

A bio-fermented feed and fermented material technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of unreduced cost, unachievable effect, unbalanced nutrition, etc., improve quality and flavor, and reduce drug delivery and casualty loss, easy to use and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

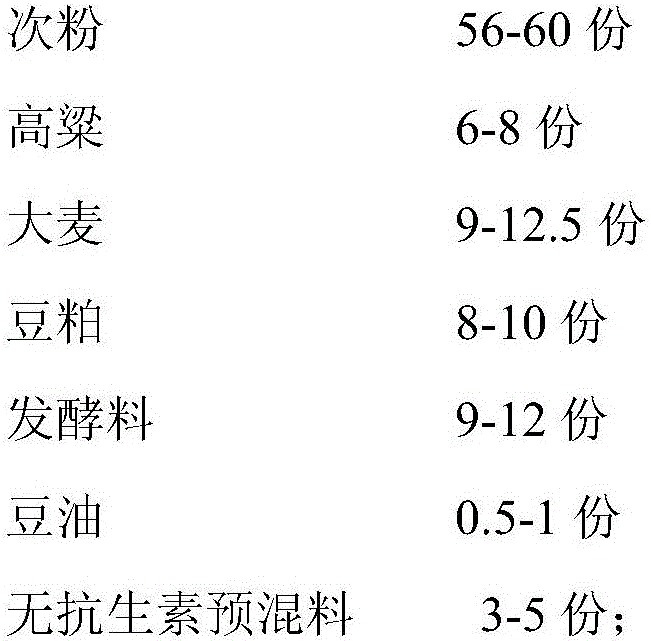

[0043] The composition of bio-fermented feed raw materials is as follows:

[0044]

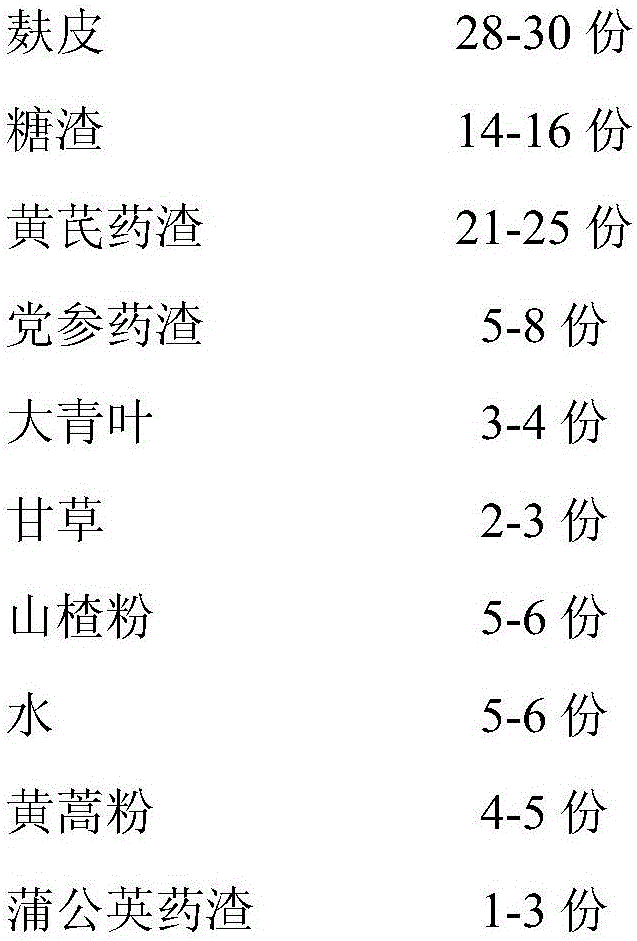

[0045] The raw material composition of fermentation material is as follows:

[0046]

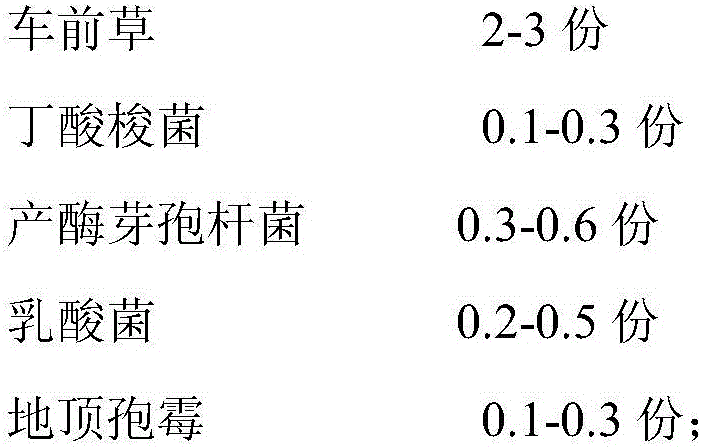

[0047] Antibiotic-free premix raw material composition is as follows:

[0048]

[0049] The preparation method of bio-fermented feed is to first put the subflour, sorghum, barley and soybean oil into the mixer, then put in the soybean meal and mix for 1 minute, then put in the fermented material and mix for 1 minute, then evenly put in the antibiotic-free premix and mix for 3 minutes After shutting down, the temperature of the feed will naturally decrease, and it will be stored in a sealed bag.

[0050] The preparation method of fermented material is as follows:

[0051] (1) Prepare water naturally cooled to 30°C, Clostridium butyricum, Bacillus zymogenes, lactic acid bacteria, Acremonium acremonium and brown sugar, dissolve brown sugar into water, then add Clostridium butyricum, Bacillus zymogene...

Embodiment 2

[0056] The composition of bio-fermented feed raw materials is as follows:

[0057]

[0058] The raw material composition of fermentation material is as follows:

[0059]

[0060]

[0061] Antibiotic-free premix raw material composition is as follows:

[0062]

[0063] The preparation method of bio-fermented feed is to first put the subflour, sorghum, barley and soybean oil into the mixer, then put in the soybean meal and mix for 1 minute, then put in the fermented material and mix for 1 minute, then evenly put in the antibiotic-free premix and mix for 3 minutes After shutting down, the temperature of the feed will naturally decrease, and it will be stored in a sealed bag.

[0064] The preparation method of fermented material is as follows:

[0065] (1) Prepare water naturally cooled to 30°C, Clostridium butyricum, Bacillus zymogenes, lactic acid bacteria, Acremonium acremonium and brown sugar, dissolve brown sugar into water, then add Clostridium butyricum, Bacil...

Embodiment 3

[0070] The composition of bio-fermented feed raw materials is as follows:

[0071]

[0072] The raw material composition of fermentation material is as follows:

[0073]

[0074] Antibiotic-free premix raw material composition is as follows:

[0075]

[0076]

[0077]The preparation method of bio-fermented feed is to first put the subflour, sorghum, barley and soybean oil into the mixer, then put in the soybean meal and mix for 1 minute, then put in the fermented material and mix for 1 minute, then evenly put in the antibiotic-free premix and mix for 3 minutes After shutting down, the temperature of the feed will naturally decrease, and it will be stored in a sealed bag.

[0078] The preparation method of fermented material is as follows:

[0079] (1) Prepare water naturally cooled to 30°C, Clostridium butyricum, Bacillus zymogenes, lactic acid bacteria, Acremonium acremonium and brown sugar, dissolve brown sugar into water, then add Clostridium butyricum, Bacill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com