Full-automatic trouser-bottom folding and ironing machine

A folding and ironing machine, fully automatic technology, applied in the field of trousers folding and ironing, can solve the problems of unguaranteed production quality, waste of fabric, and low production efficiency, so as to ensure stickiness and folding and ironing quality, strong market competitiveness, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

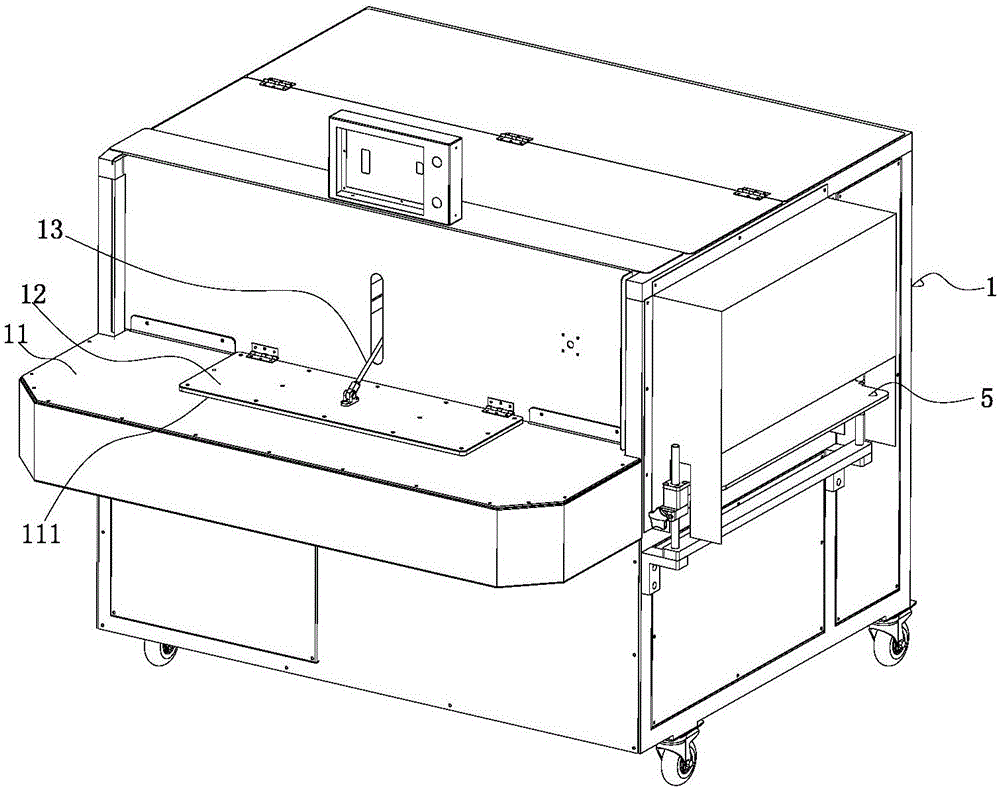

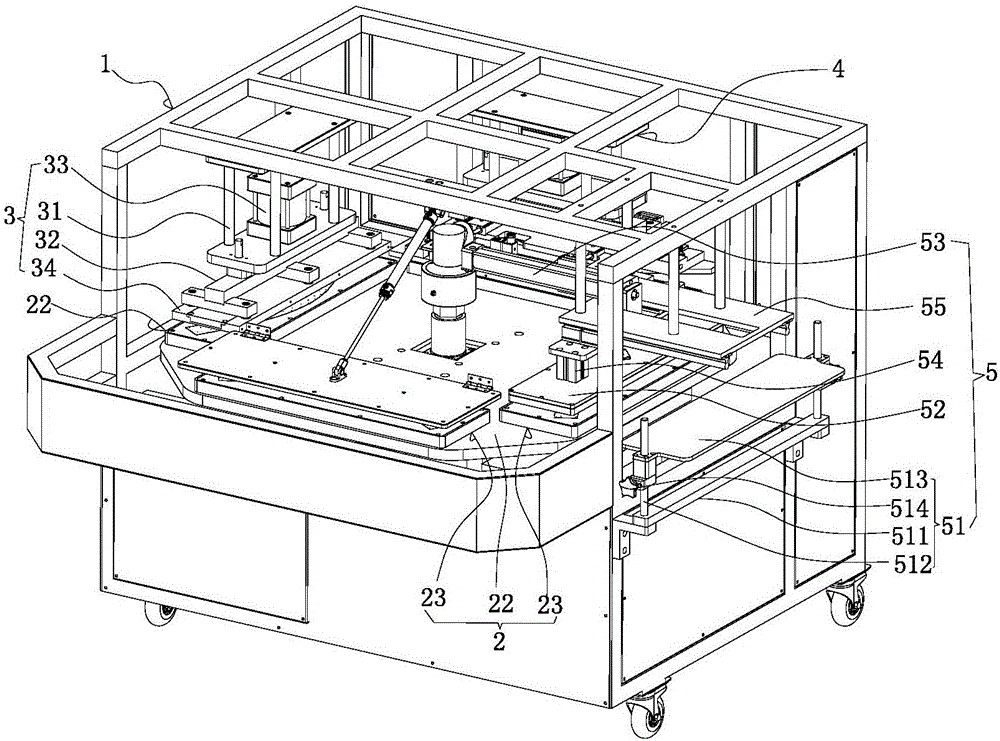

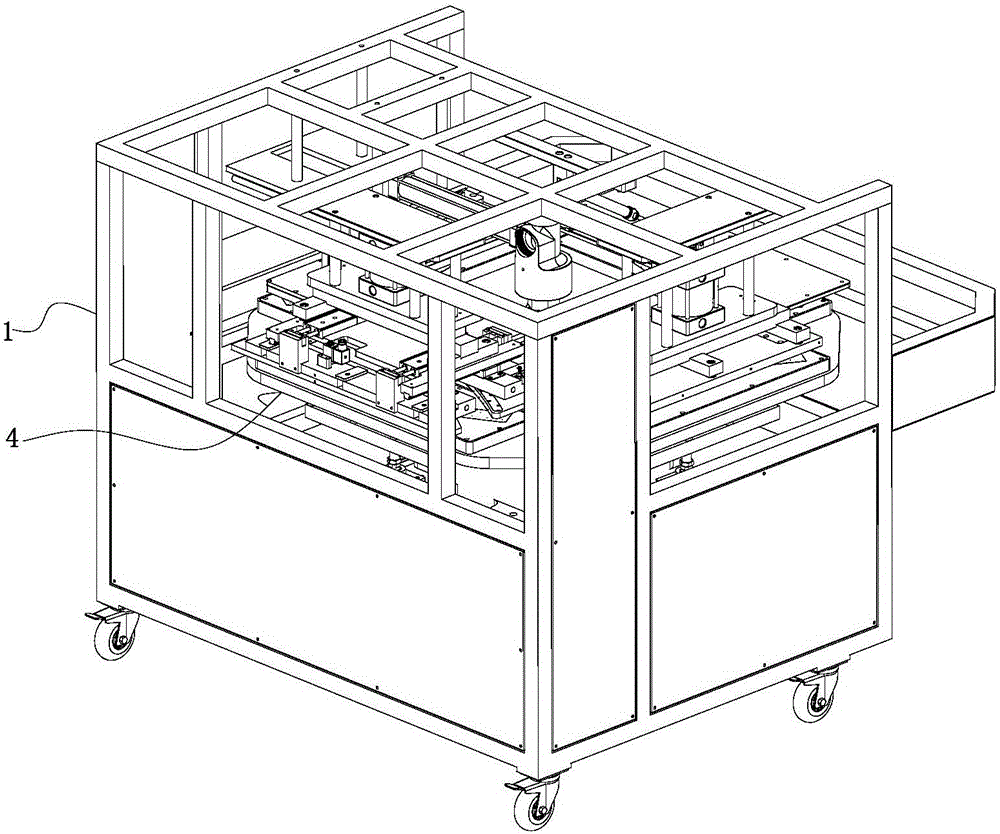

[0035] See Figure 1-13 As shown, it is a fully automatic trousers ironing machine, which includes: a frame 1 and a rotary table device 2 installed on the frame 1, a sticking device 3, a folding and ironing device 4, and an automatic discharging device 5, wherein , the gluing device 3, the ironing device 4, and the automatic discharging device 5 are located above the rotary table device 2.

[0036] The front end of the frame 1 is provided with a machine platform 11, the machine platform 11 is provided with a feeding window 111, and the frame 1 is provided with a safety cover 12 that can automatically open and close the feeding window 111; specifically, One side of the safety cover 12 is hinged to the machine 11 through a hinge, and the other side of the safety cover 12 is connected to the frame 1 through a telescopic air rod 13, and the safety cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com