Filter-press plate for filter-press unit

A technology of filter press plate and filter unit, which is applied in the direction of filtration separation, water/sludge/sewage treatment, sludge treatment, etc. It can solve the problems of increasing drainage resistance, lack of support, and difficulty in free falling of mud cake, etc., to achieve The unobstructed guarantee of liquid penetration and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

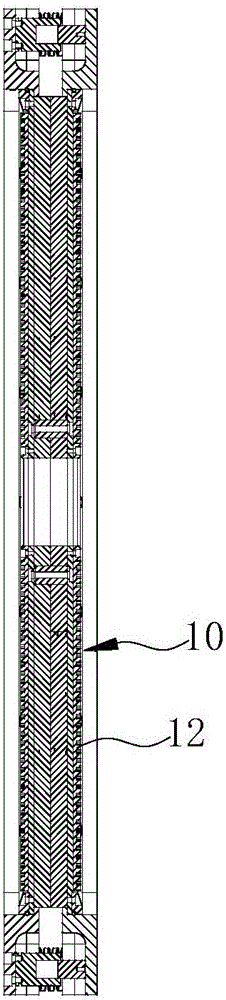

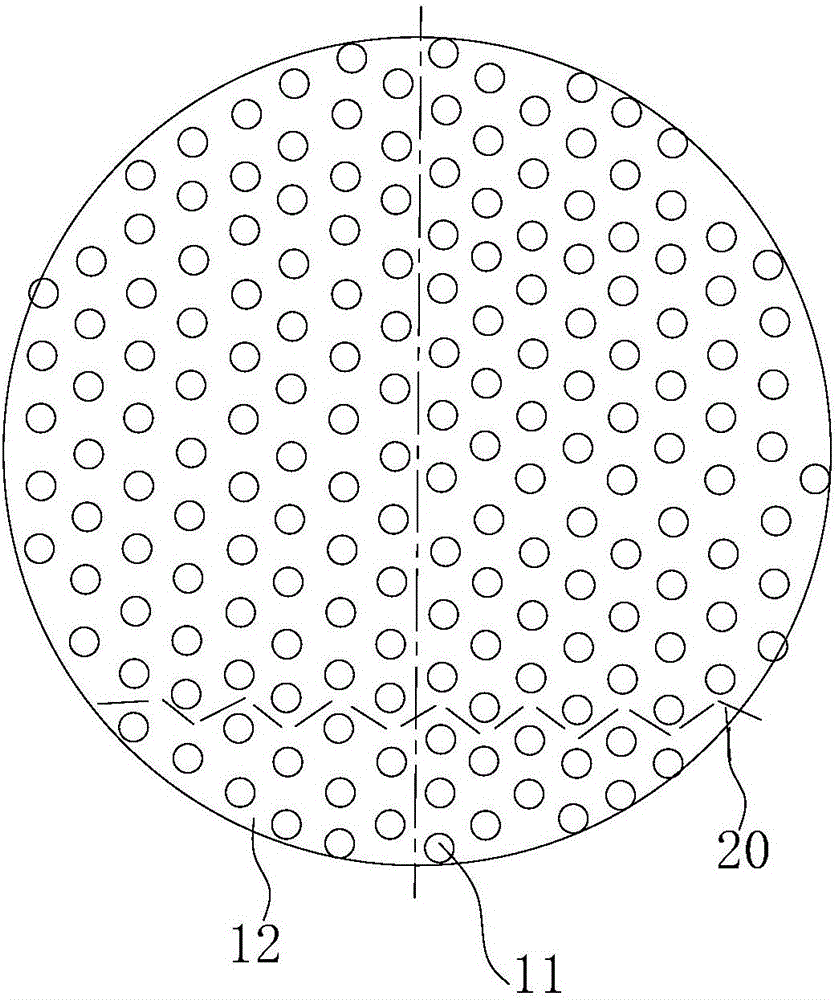

[0015] Such as image 3 As shown, considering the convenience of processing the small protrusions 11, the flow guide area 20 on the filter press plate 10 is arranged in a folding shape at least in the horizontal direction. The horizontal direction here refers to that when the filter press plate 10 is in the working state of the vertical arrangement, the flow guide area 20 in the horizontal direction is formed, because the water flows from top to bottom, if there is a blockage in the flow guide area 20 in the horizontal direction The sludge ribs block the path of water flowing downward, so at least ensure that the diversion area 20 is at least folded in the horizontal direction, so that the path of water flowing downward will not be blocked, even if there are sludge ribs The strips are in the flow guide area 20 in the horizontal direction, but because the flow guide area 20 is arranged in a folded shape, the bent part will easily break due to stress concentration and be washed ...

Embodiment 2

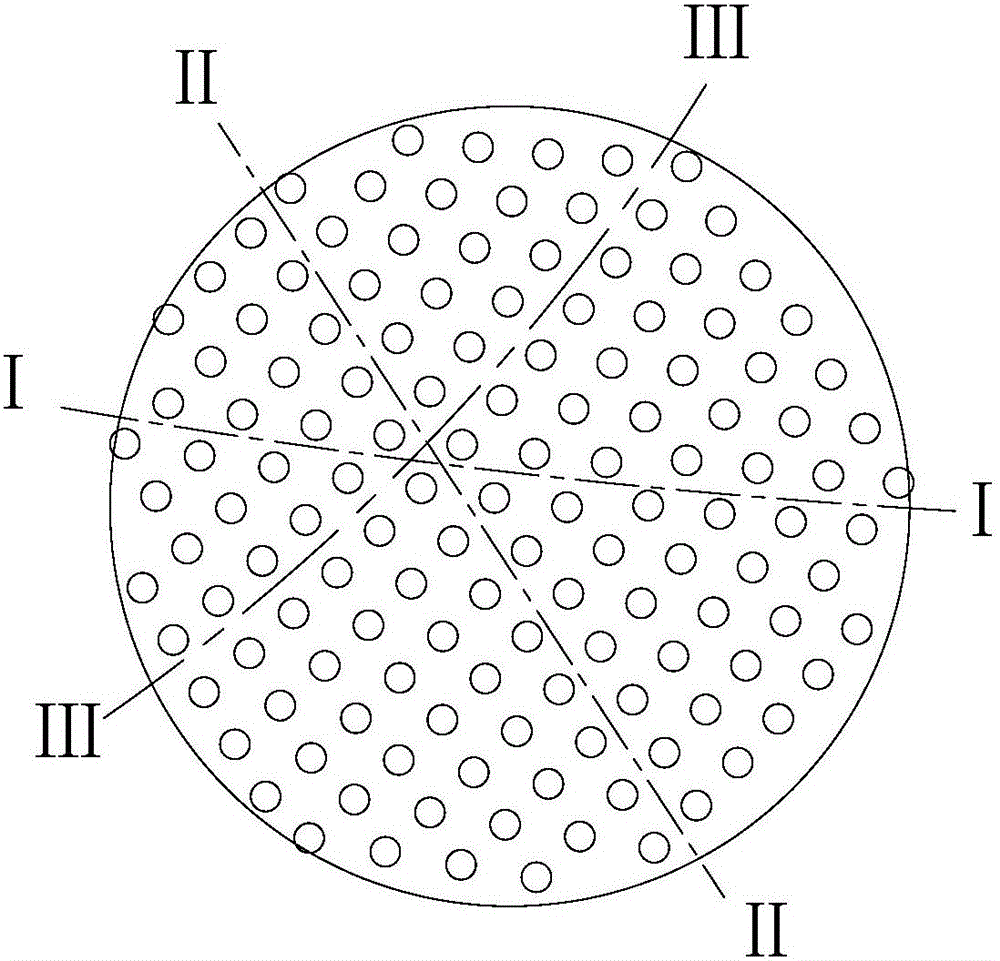

[0018] As shown in FIG. 4 , the filter press plate 10 is in the shape of a circular plate, and the guide area 20 is connected in the radial direction and / or circumferential direction of the plate surface of the filter press plate 10 to form a folding arrangement.

Embodiment 3

[0020] As shown in FIG. 5 , the filter press plate 10 is in the shape of a square plate, and the diversion area 20 is connected in a direction parallel to and / or at an angle to the sides of the filter press plate 10 to form a folding arrangement.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap