Petrochemical engineering pipe cleaner

A pipeline cleaning and petrochemical technology, which is applied to chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of single cleaning brush, poor cleaning effect, and inability to adjust, and achieves simple structure, convenient installation, The effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

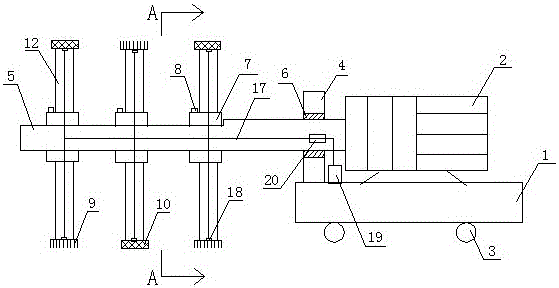

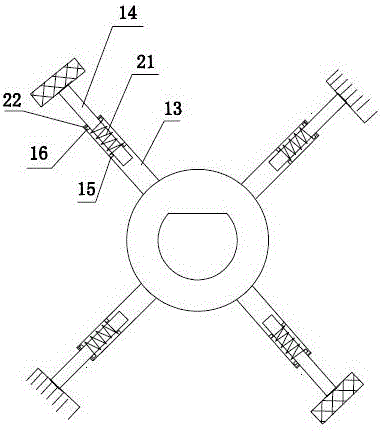

[0023] Such as figure 1 , figure 2 As shown, a petrochemical pipeline cleaner includes a base 1, a motor 2, a column 4, a rotating shaft 5 and a cleaning device. The column 4 and the motor 2 are arranged on the base 1, and the column is provided with a circular hole. There is a bearing 6 inside, and the cleaning device is installed on the rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the motor 2 through (or passing through) the bearing 6. The cleaning device of the present invention includes a connecting plate 7 and a connecting rod 12 , the connecting disc 7 is sleeved on the rotating shaft 5 and fixed with the rotating shaft 5 , there are at least two connecting discs 7 , which are uniformly sleeved on the rotating shaft 5 .

[0024] The connecting rod 12 is composed of two sections, including a fixed sleeve 13 and a sliding guide rod 14. The fixed sleeve 13 is a round tube, and the sliding guide rod 14 is a cylinder. The radial setting of...

Embodiment 2

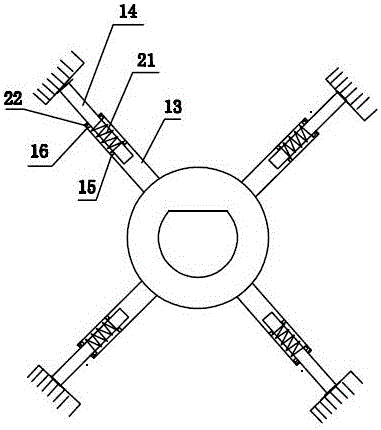

[0031] Such as figure 1 and image 3 As shown, a petrochemical pipeline cleaner includes a base 1, a motor 2, a column 4, a rotating shaft 5 and a cleaning device. The column 4 and the motor 2 are arranged on the base 1, and the column is provided with a circular hole. There is a bearing 6 inside, and the cleaning device is installed on the rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the motor 2 through (or passing through) the bearing 6. The cleaning device of the present invention includes a connecting plate 7 and a connecting rod 12 , the connecting disc 7 is sleeved on the rotating shaft 5 and fixed with the rotating shaft 5 , there are at least two connecting discs 7 , which are uniformly sleeved on the rotating shaft 5 .

[0032] The connecting rod 12 is composed of two sections, including a fixed sleeve 13 and a sliding guide rod 14. The fixed sleeve 13 is a round tube, and the sliding guide rod 14 is a cylinder. The radial arrangeme...

Embodiment 3

[0040] Such as figure 1 and Figure 4 As shown, a petrochemical pipeline cleaner includes a base 1, a motor 2, a column 4, a rotating shaft 5 and a cleaning device. The column 4 and the motor 2 are arranged on the base 1, and the column is provided with a circular hole. There is a bearing 6 inside, and the cleaning device is installed on the rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the motor 2 through (or passing through) the bearing 6. The cleaning device of the present invention includes a connecting plate 7 and a connecting rod 12 , the connecting disc 7 is sleeved on the rotating shaft 5 and fixed with the rotating shaft 5 , there are at least two connecting discs 7 , which are uniformly sleeved on the rotating shaft 5 .

[0041] The connecting rod 12 is composed of two sections, including a fixed sleeve 13 and a sliding guide rod 14. The fixed sleeve 13 is a round tube, and the sliding guide rod 14 is a cylinder. The radial setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com