Automobile wheelcover covered edge forming device

A molding device, a technology for automobile wheels, applied in the directions of wheels, transportation and packaging, vehicle parts, etc., can solve the problems affecting the pressing efficiency of wheel covers, and achieve the effect of reducing equipment investment, ensuring the quality of hemming molding, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

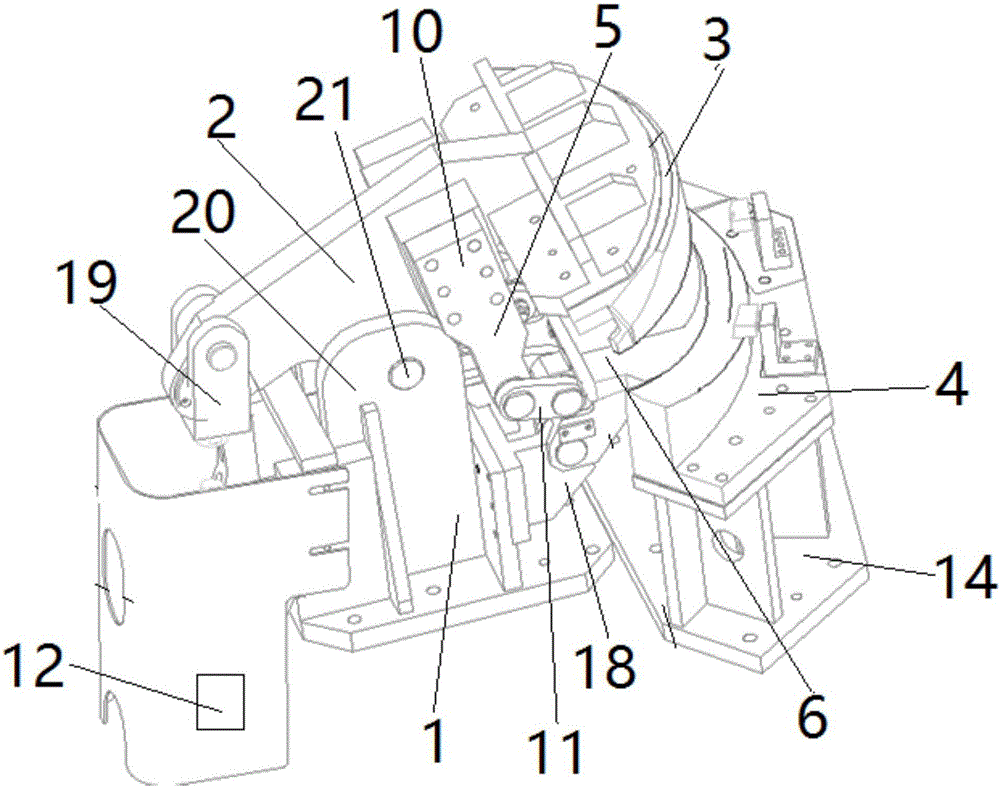

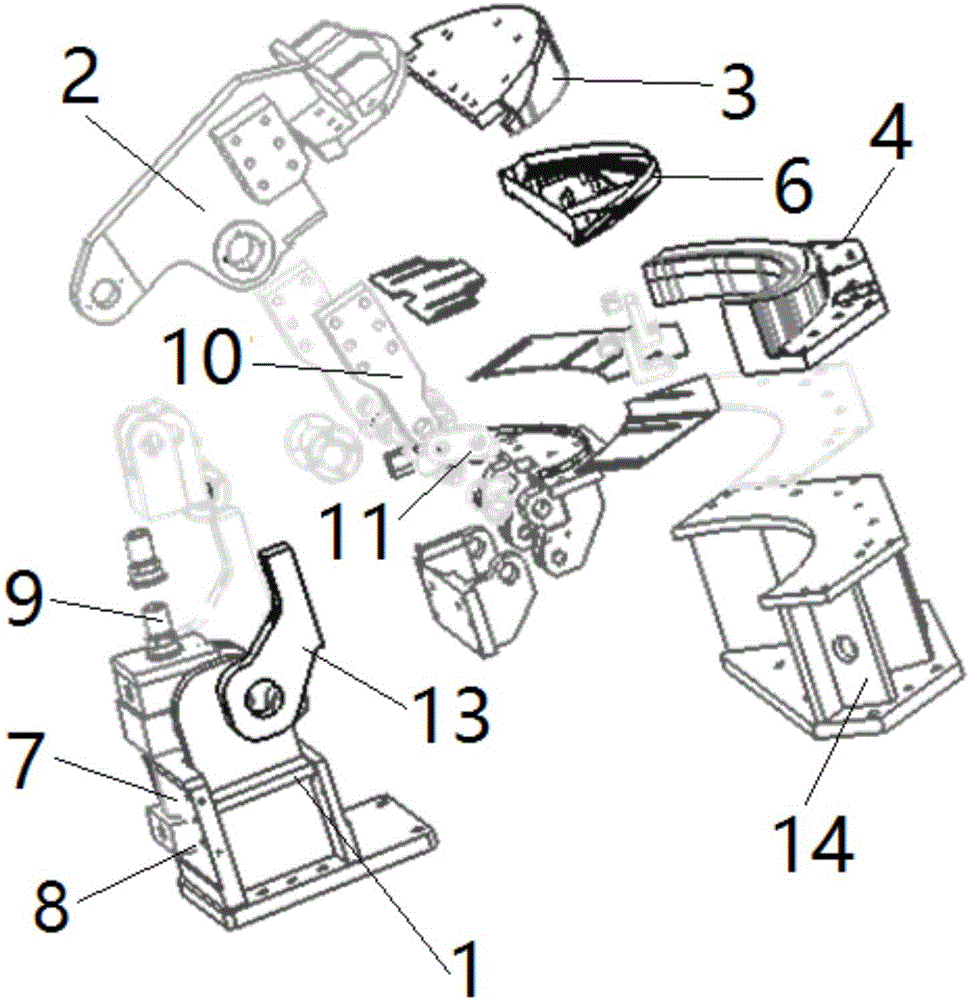

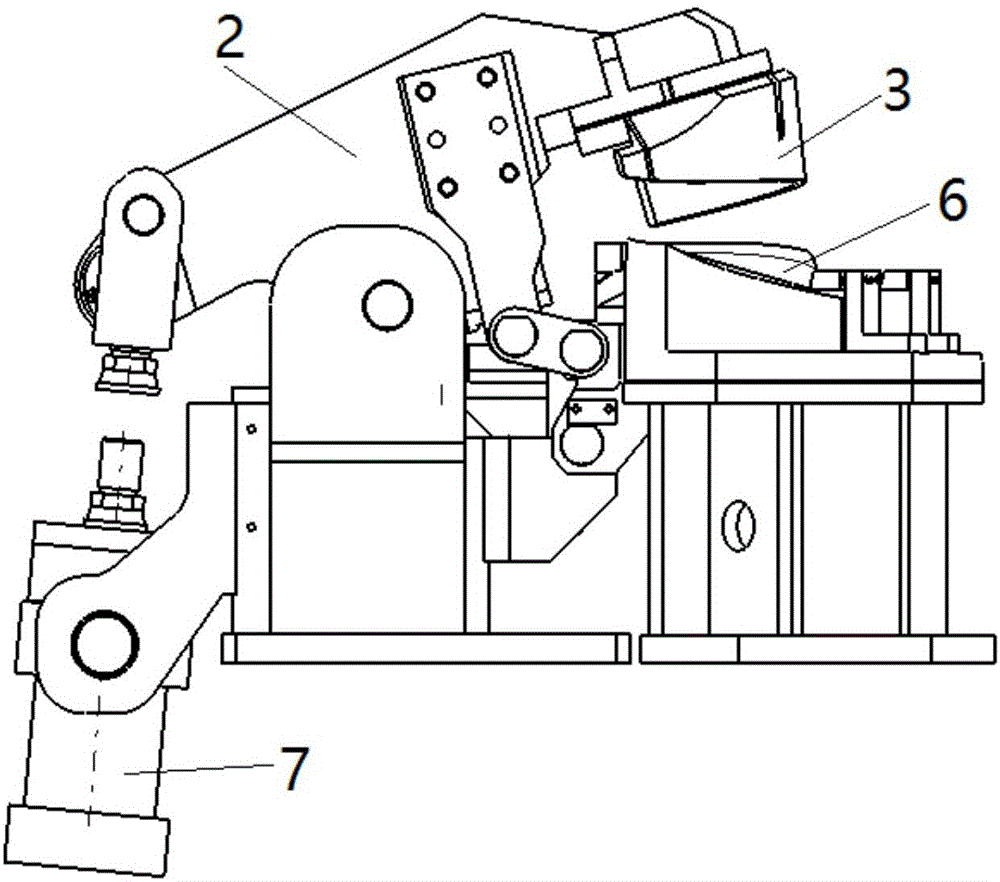

[0022] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0023] as attached figure 1 - attached Figure 5 As shown, the present invention is an automobile wheel cover hemming forming device. The automobile wheel cover hemming forming device includes a device base 1, a pressing arm 2 is movably installed on the device base 1, and a pressing arm 2 is installed on the pressing arm 2. Membrane 3, a reference membrane 4 is set under the pressing film 3, a hinge part 5 is also installed on the pressing arm 2, and the hinge part 5 is connected with the pre-bent film 6. When the pressing arm 2 rotates, the pressing arm 2 is set It is a structure capable of driving the pre-bent fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com