Casting head system on DISA line for producing small circular-ring shaped HT200 casting and design method thereof

A technology of gating risers and gating systems, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems that affect the shape and performance of castings, reduce the load-bearing surface area, weaken the strength and hardness of castings, etc., and achieve improved Effect of scientificity and rigor, saving space, and preventing quality differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

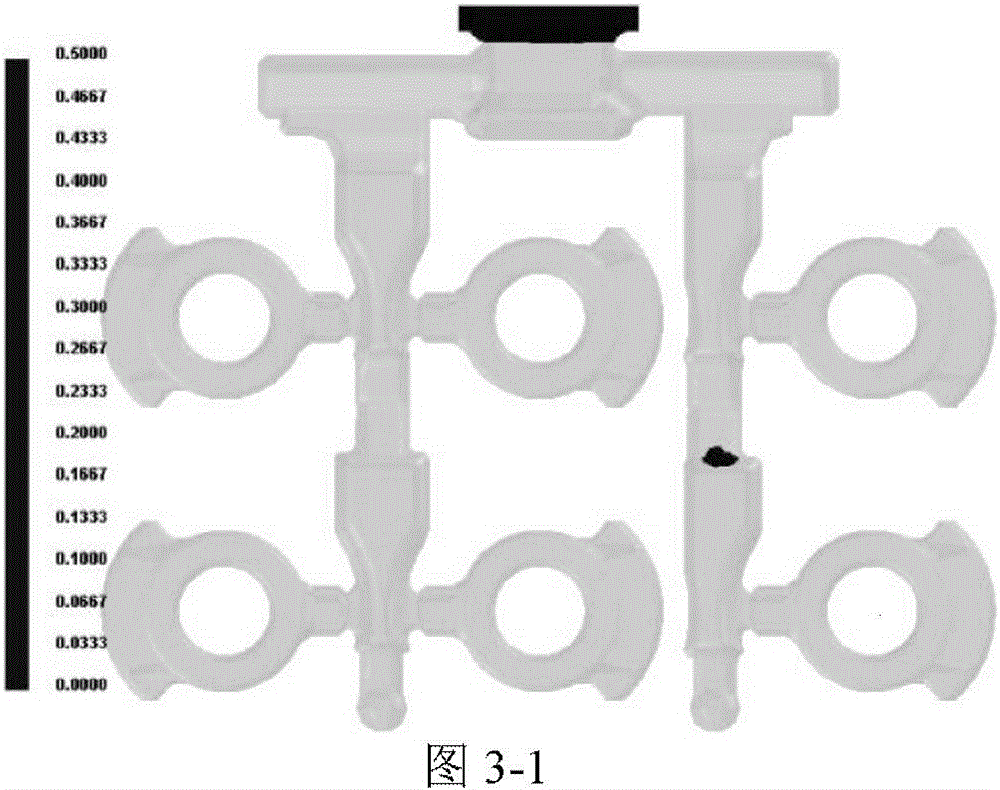

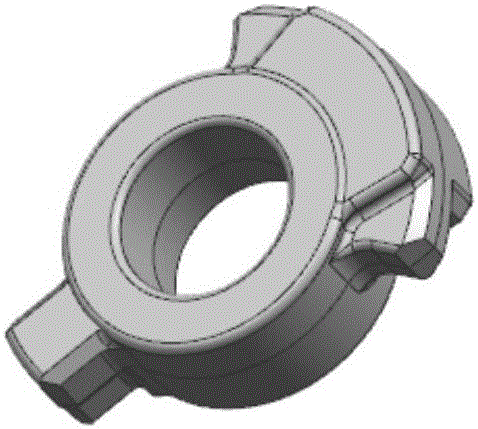

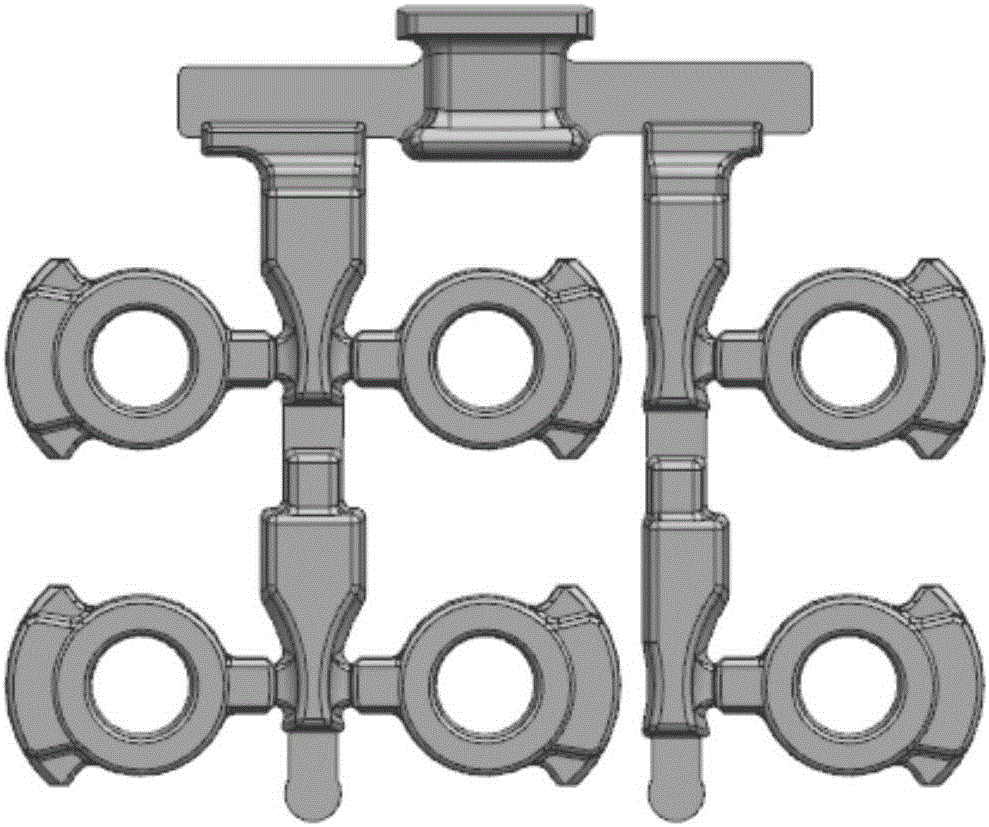

[0042] In this embodiment, the DISA line of the small ring HT200 castings is produced. The riser system includes a riser 1, a riser neck 2 and a gating system, and the gating system includes a sprue 3, a runner 5 and an inner sprue 6 , the cross-section of each sprue is isosceles trapezoidal, and the area of the cross-section of each sprue is different. The left and right sides of the runner 5 are respectively connected with the sprue 3, and the sprue on the left is divided into upper and lower layers. Four castings, two castings in each layer, and symmetrically distributed with the left sprue as the axis, and two castings 7 are arranged in the upper and lower layers on the left side of the right sprue; the lower part of each casting 7 passes through the corresponding The ingate 6 communicates with the corresponding sprue 3, and the angle between each ingate and the horizontal direction is 30°, and the cross-sectional area of the upper and lower layers of the ingate is calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com