A kind of copper mold die-casting forming mold and method thereof

A technology of die-casting molding and copper molds, which is applied in the field of copper alloy die-casting, can solve the problems of short service life and quality defects of copper molds, and achieve the effects of high accuracy of external dimensions, long service life and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

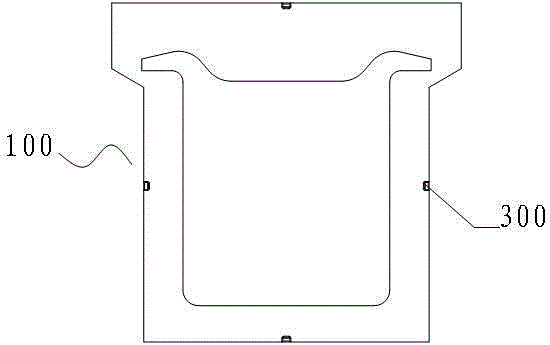

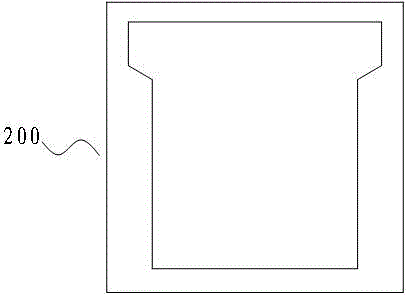

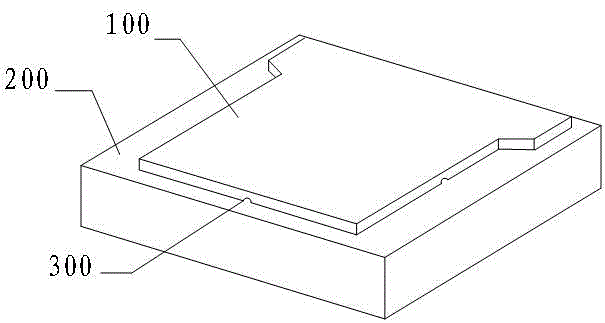

Image

Examples

Embodiment

[0029] Heat and melt the copper to obtain copper water with a copper content of 99.9%. Pour 3.3 tons of copper water into the lower mold at a casting temperature of 1150 degrees. After the copper water is poured, press the upper mold in a certain way. into the lower mold.

[0030] The process of pressing the upper mold into the lower mold is divided into two steps. The first step is to press the upper mold into the position 4~8mm away from the lower mold, and stay for 3~6 minutes; the second step is to completely press the upper mold into the lower mold. If there is too much copper water in the second step, the excess copper water will flow out from the overflow tank of the upper mold. In the present invention, the process of pressing the upper mold into the lower mold is divided into two steps. The advantage is that in the first step, the purpose of leaving a gap and staying for a certain period of time is to allow the gas and impurities in the copper water to float up, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com