Welding method for guaranteeing tight connection between magnetic steel for accelerometer and base

A technology of fastening connection and welding method, which is applied in the field of welding to ensure the fastening connection between the magnetic steel and the base of the accelerometer, can solve the problems of high scrap rate, easy cracks in components and high cost of die-casting molds, and improve the welding performance. , The effect of high production qualification rate and high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

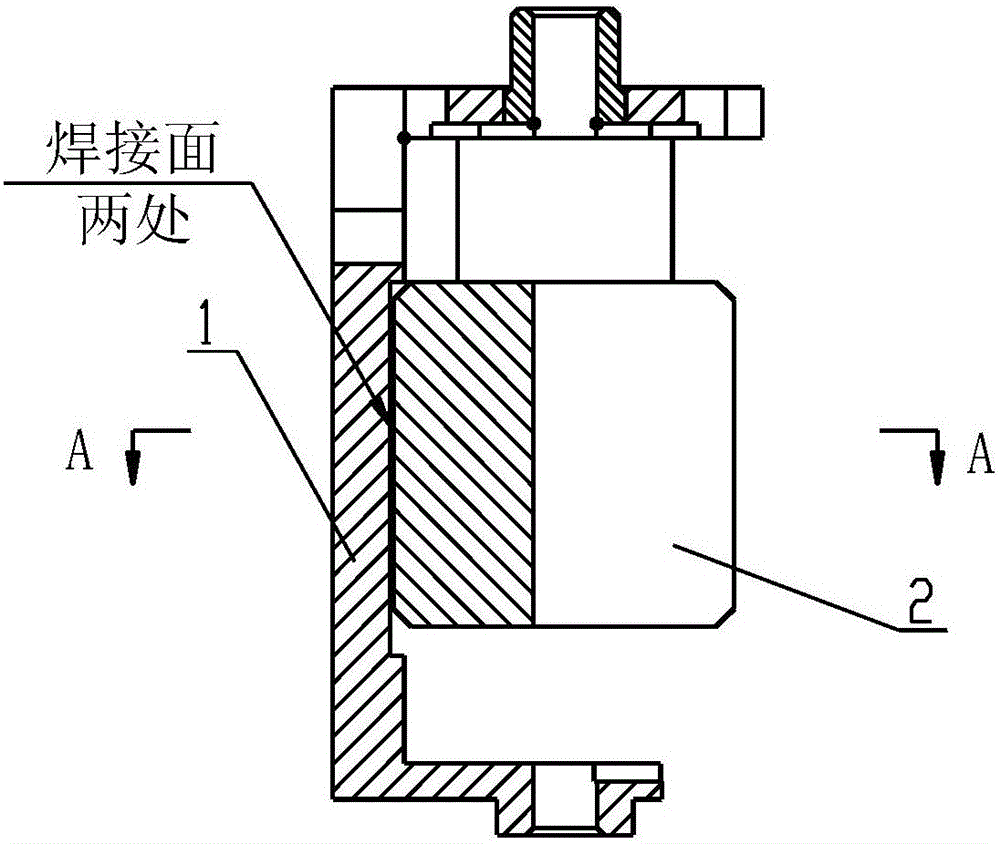

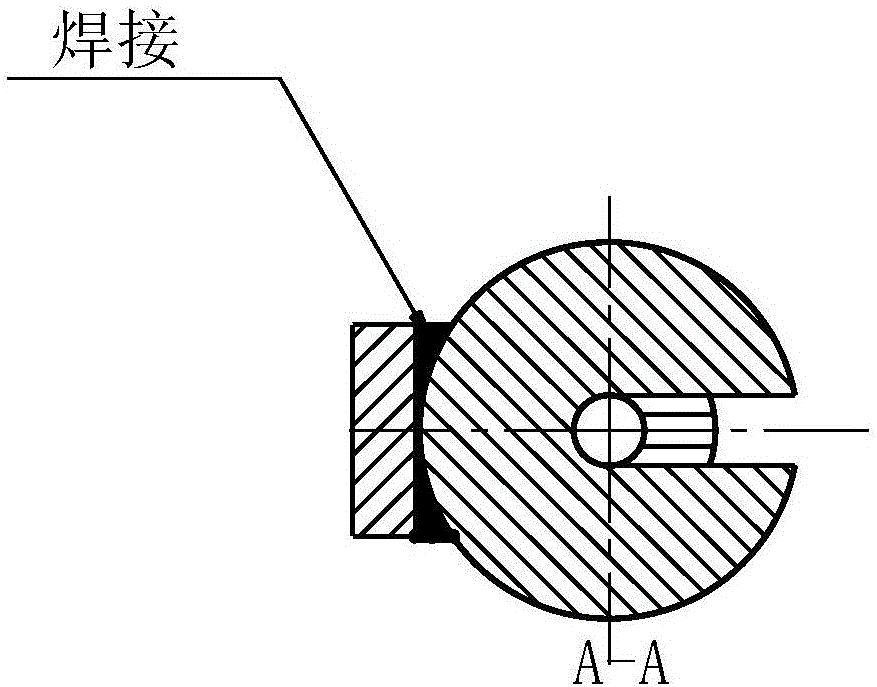

[0021] A welding method for ensuring that the accelerometer is firmly connected to the base with the magnetic steel, the method takes the following steps:

[0022] 1) A layer of nickel is plated on the surface of the magnetic steel with a thickness of 5μ to improve the welding performance of the magnetic steel;

[0023] 2) Put the magnetic steel and the base on the V-shaped fixture, so that the cylindrical surface of the magnetic steel is tangent to the V-shaped surface of the V-shaped fixture, and ensure that the coaxiality between the base and the magnetic steel is not greater than 0.05mm;

[0024] 3) Coating acidic flux 201 on the welding surface of the base, and using the acidic flux to corrode and remove the surface treatment layer on the welding surface of the base;

[0025] 4) The temperature of the electric soldering iron is controlled between 150°C and 250°C, and the base and the magnetic steel are welded with S-Sn60PbSbA solder, so that the magnetic steel and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com