Direct error compensation technique for five-degree-of-freedom mixed-connected robot

An error compensation and robotics technology, applied in the field of robotics, can solve problems such as excessive parameterization of models, deviation of error identification results from the true value, complex models, etc., and achieve the effects of simple calculation methods, avoiding long time-consuming, and high calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] This embodiment is directed to a direct error compensation technology for a five-degree-of-freedom hybrid robot with a rotating bracket disclosed in Chinese patent publication No. CN104985596A.

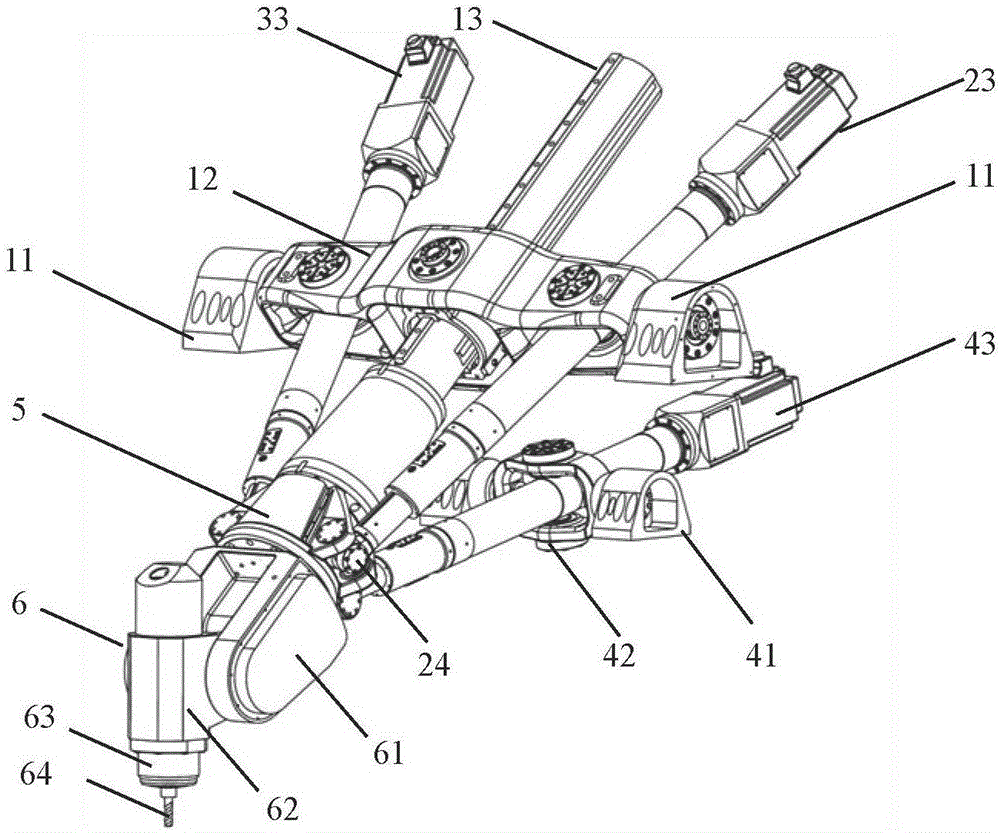

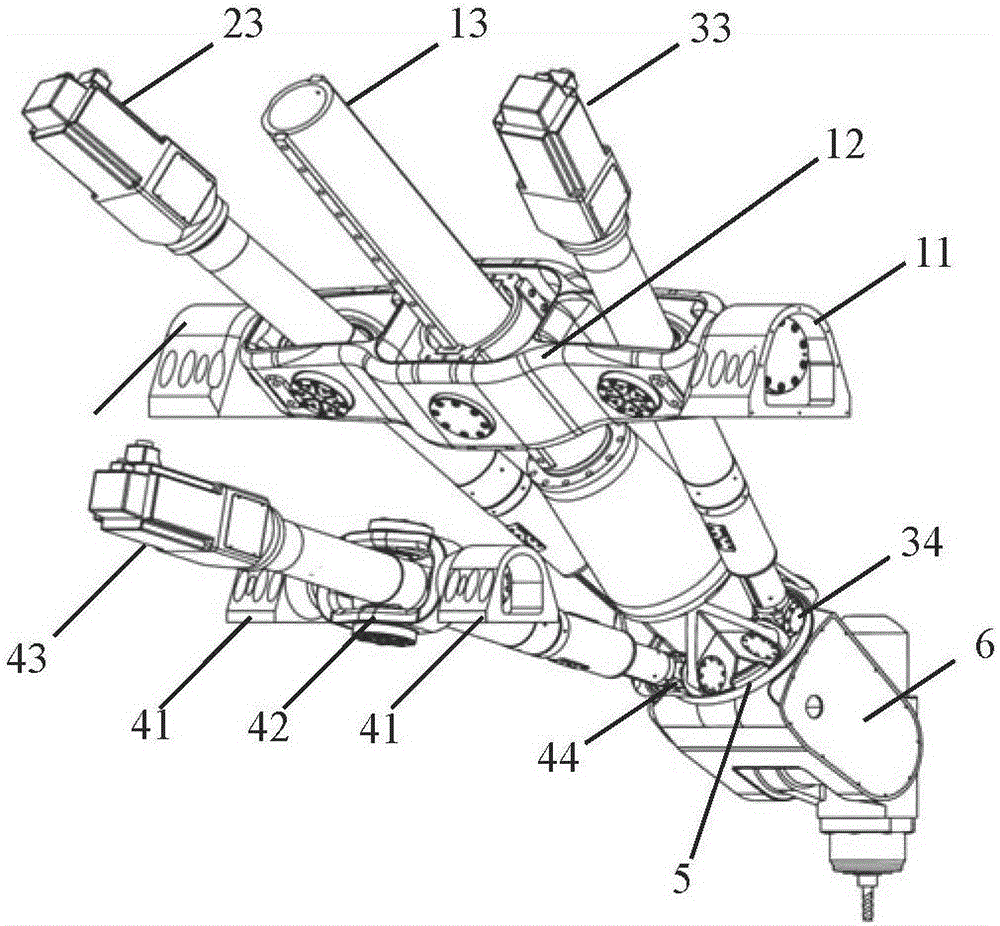

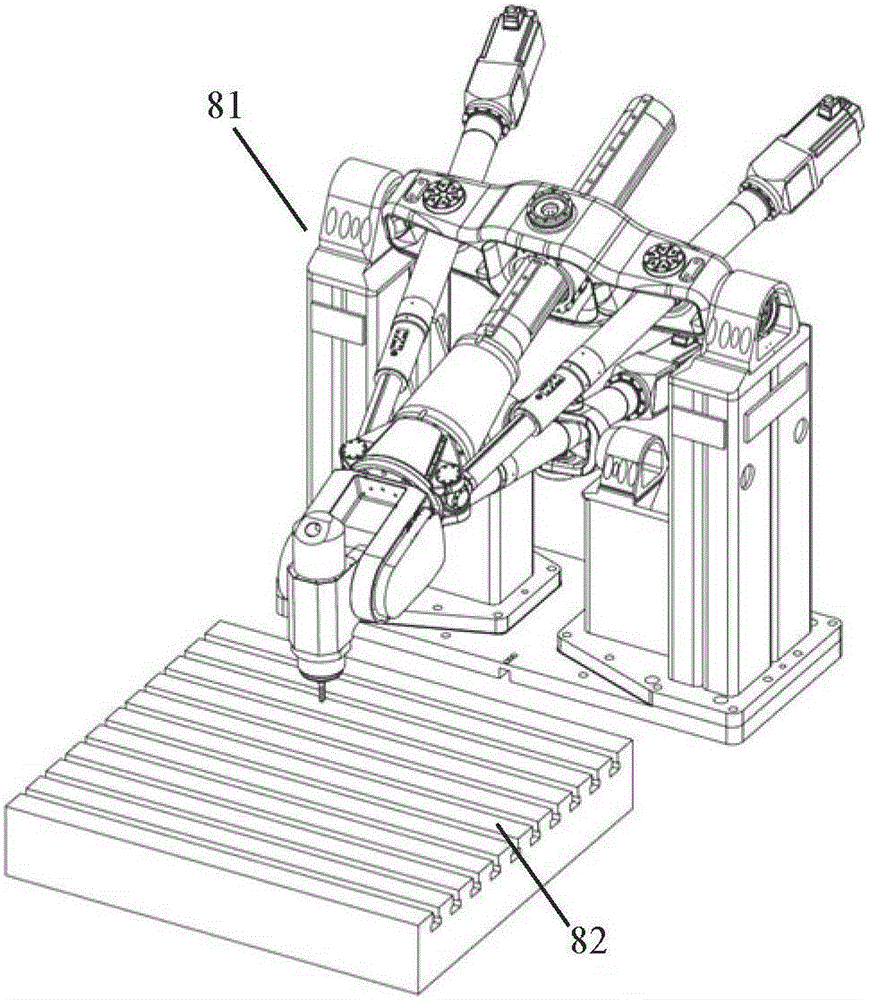

[0051] Attached below figure 1 And attached figure 2 The structure of the five-degree-of-freedom hybrid configuration equipment disclosed in CN104985596A is briefly described. The five-degree-of-freedom hybrid configuration equipment consists of a three-degree-of-freedom parallel mechanism with one translation and two rotations and a series-connected rotor with two rotational degrees of freedom connected in series. The series-connected rotor 6 is fixed on The moving platform of the parallel mechanism. The tandem rotary head 6 connected in series at the end of the moving platform 5 is a two-degree-of-freedom A / C swing head, including a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com