Magnesium oxide board cutting and separating device and cutting method thereof

A technology of separation device and glass magnesium board, which is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of circular saw blade wear, high equipment cost, complex structure, etc., and achieve the effect of short cutting time and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

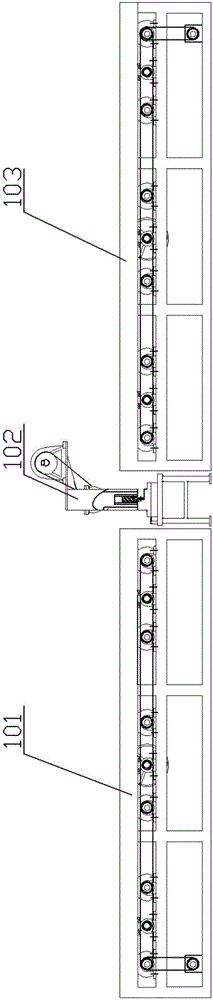

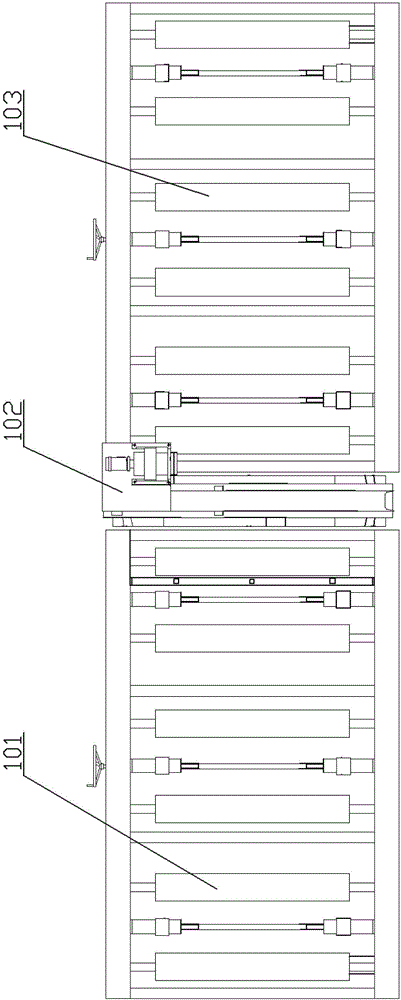

[0039] refer to Figure 1 to Figure 2 , The invention provides a glass magnesium plate cutting and separating device. Including conveying assembly, cutting assembly and separating assembly. The conveying component conveys glass magnesium boards of different width specifications, and at the same time, three photoelectric sensors detect the speed and inclination of the glass magnesium boards. The cutting component adjusts its position in real time according to the inclination of the glass magnesium board to cut the glass magnesium board. The separation component is used to separate the cut glass magnesium sheet.

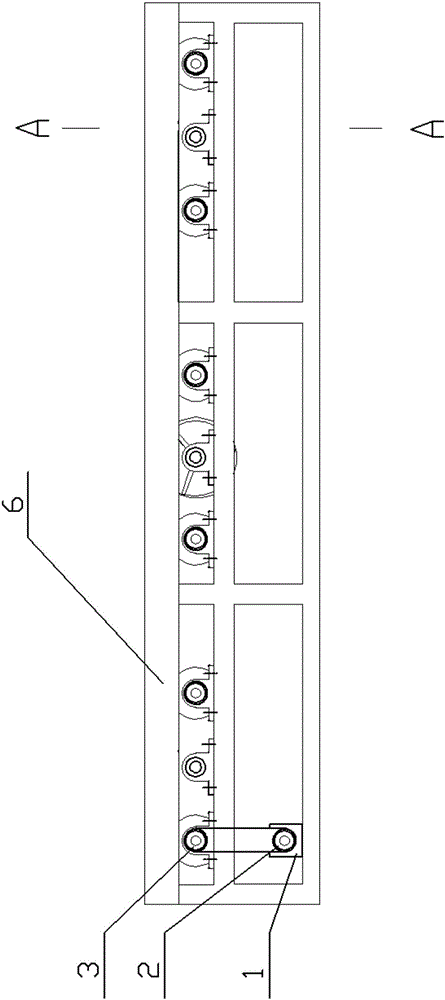

[0040] refer to Figure 3 to Figure 6 , the conveying assembly includes: motor 1, small double sprocket 2, double sprocket 3, seated bearing 4, frame 6, screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com