Composite material for packaging

A composite material and packaging technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problem that packaging materials are difficult to meet a number of special needs, and achieve fast speed and effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

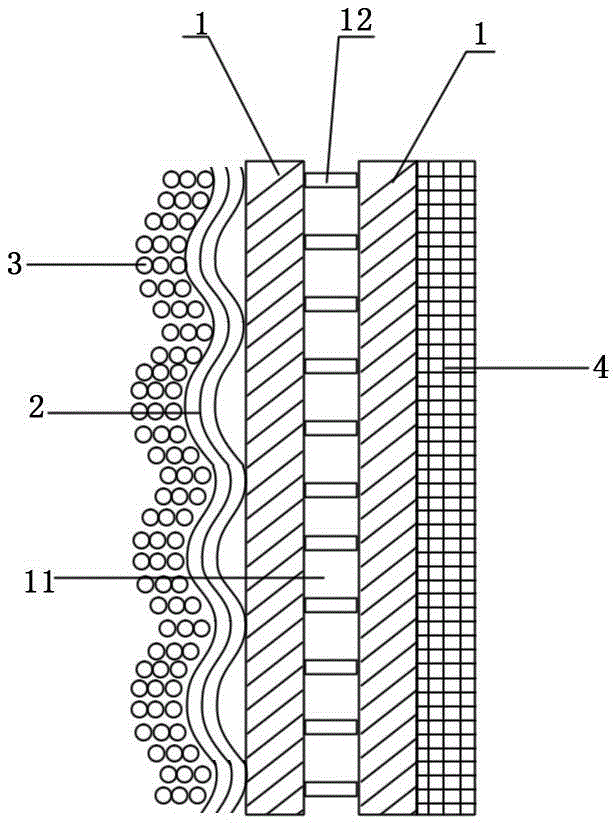

[0011] Such as figure 1 As shown, a composite material for packaging is characterized in that it includes a base material layer (1), an isolation cavity (11) is provided in the middle of the base material layer (1), and multiple A connecting column (12), the isolation cavity can play a sound insulation effect during use, an insulation layer (2) is provided on the outside of the base material layer (1), and nano-ceramic particles are arranged on the surface of the insulation layer A reflective layer (3), in which nano-ceramic particles are resistant to high and low temperatures, and has good air permeability and water resistance, thereby ensuring practicality, and an alkali-resistant glass fiber grid is provided on the inner side of the substrate layer cloth (4).

[0012] Preferably, the thermal insulation board is in the shape of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com