A high-efficiency continuous membrane screening self-priming liquid vinegar fermentation equipment and process

A continuous membrane, self-priming technology, applied in the field of vinegar brewing, can solve the problems of long service life of bacteria, low acid production rate, easy aging, etc., and achieve the effects of simple operation, reduced power waste, and reasonable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

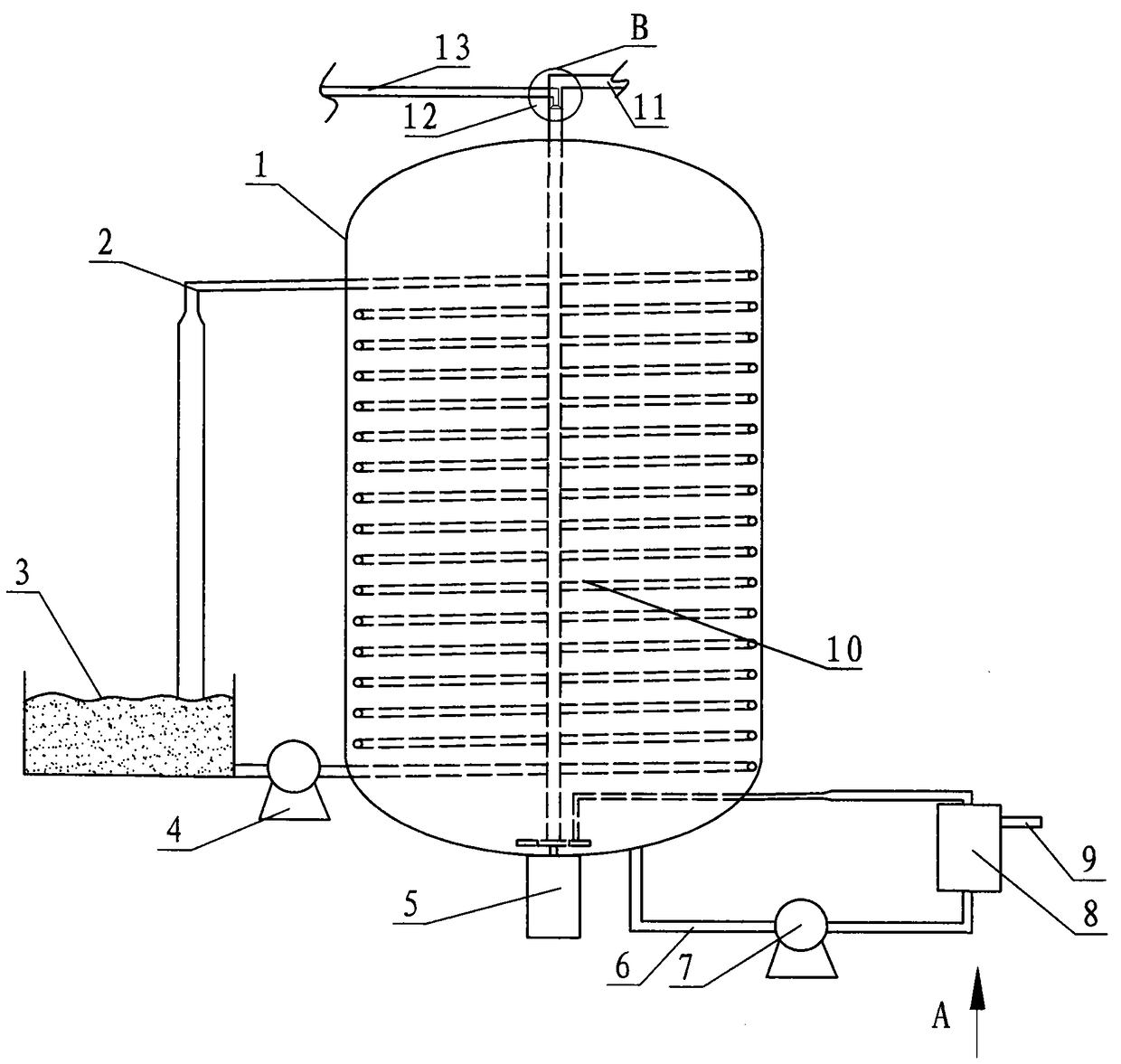

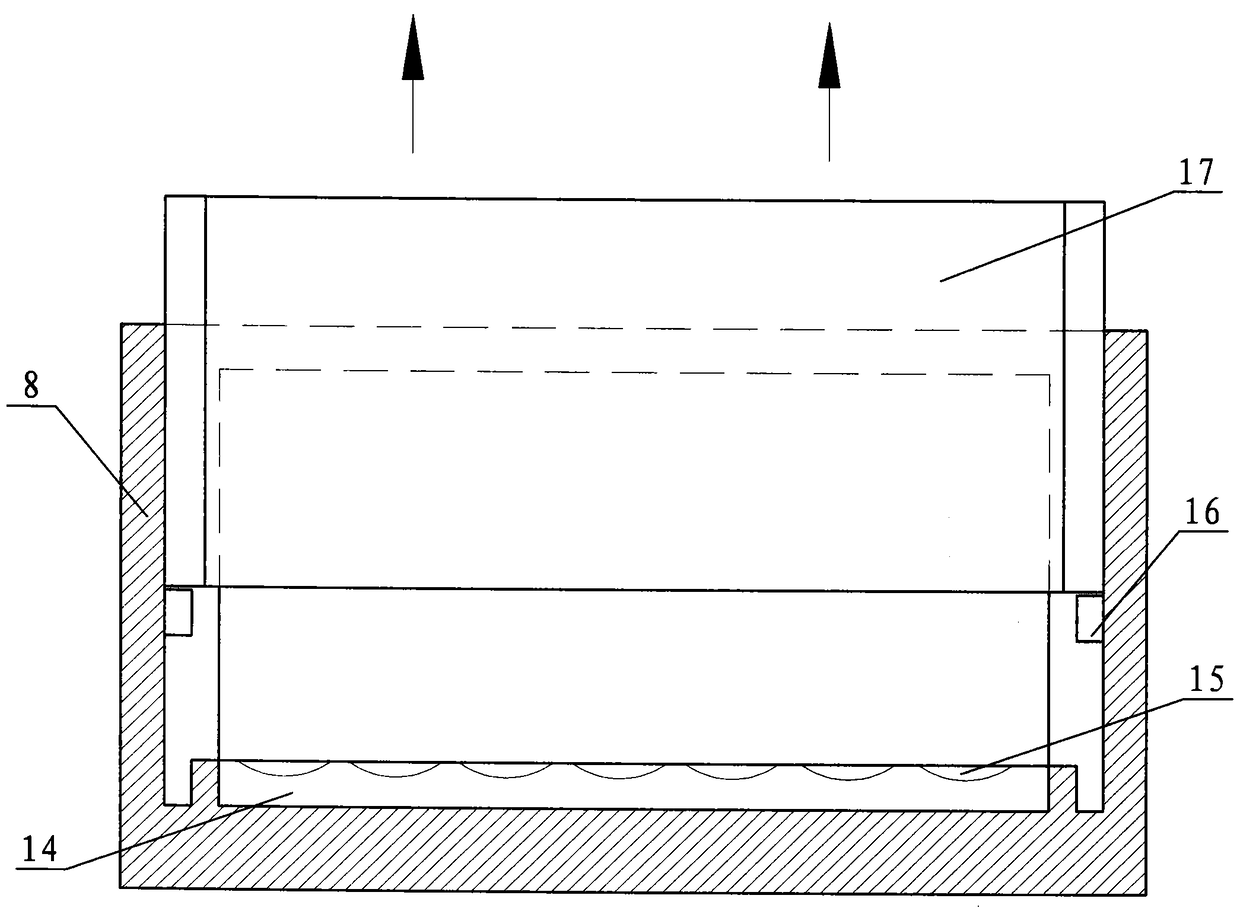

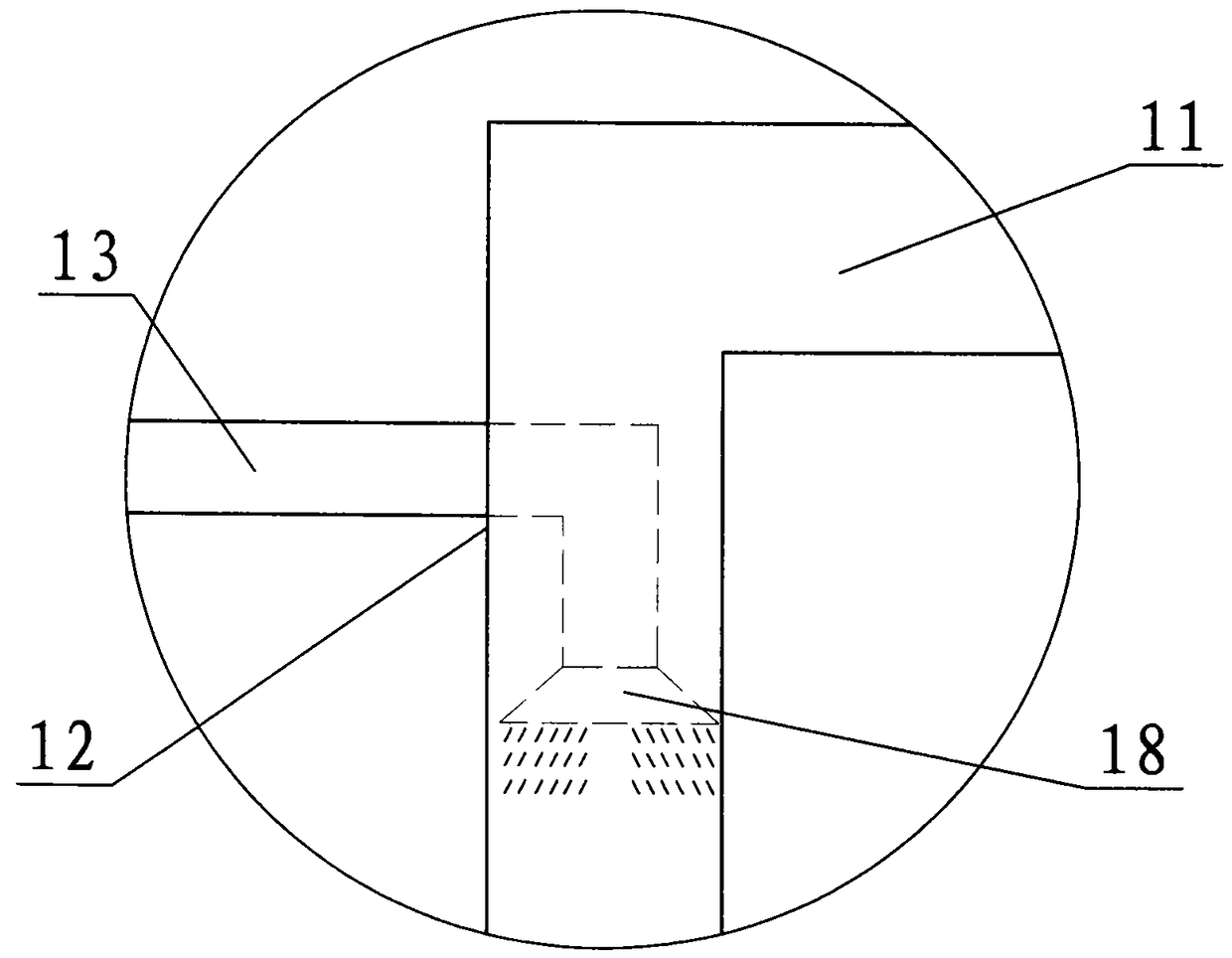

[0030] Such as figure 1 As shown, a spiral cooling pipe 10 is arranged in the tank body 1 to reduce the heat energy generated during the fermentation process in the tank body. The spiral cooling pipe 10 runs through the entire tank body from top to bottom in the tank body 1, so that the heat dissipation effect is more efficient and stable. One end of the spiral cooling pipe 10 is connected to the cooling water pipe 2 entering from the lower part of the tank body 1, and the other end of the spiral cooling pipe 10 is connected to the cooling water pipe 2 entering from the upper part of the tank body 1; the cooling water pipe 2 is connected to the cold water pool 3 to form a cooling water pipeline. The spiral cooling pipe 10 passes through the cooling water pipe 2, absorbs the heat energy in the tank 1, discharges it to the cold water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com