Passive heat dissipation evaporator and passive heat dissipation system

A passive, evaporator technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of loose contact between capillary core and evaporator, reduce capillary core permeability, gap in heat dissipation capacity, etc., to improve boiling limit and critical heat flow Density, conflict avoidance, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

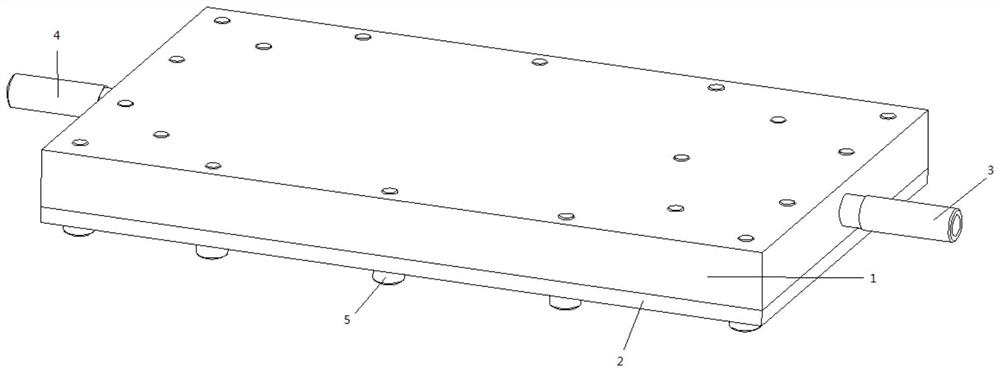

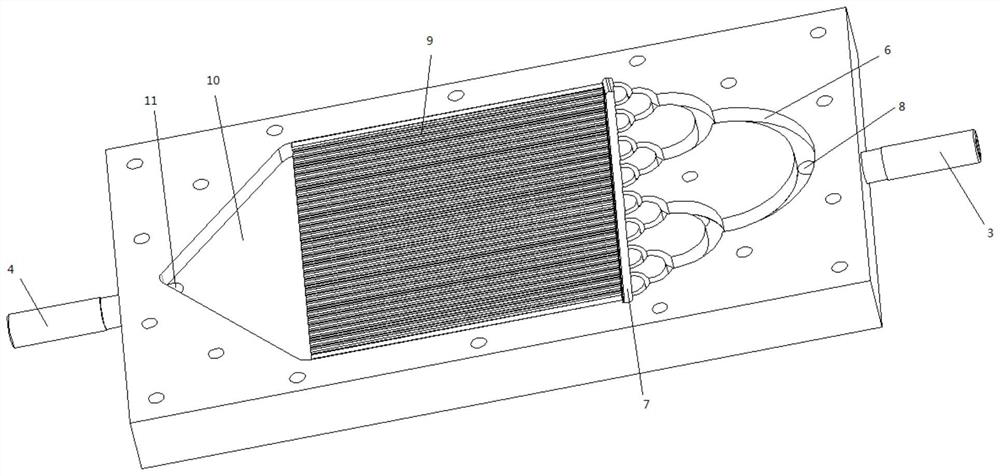

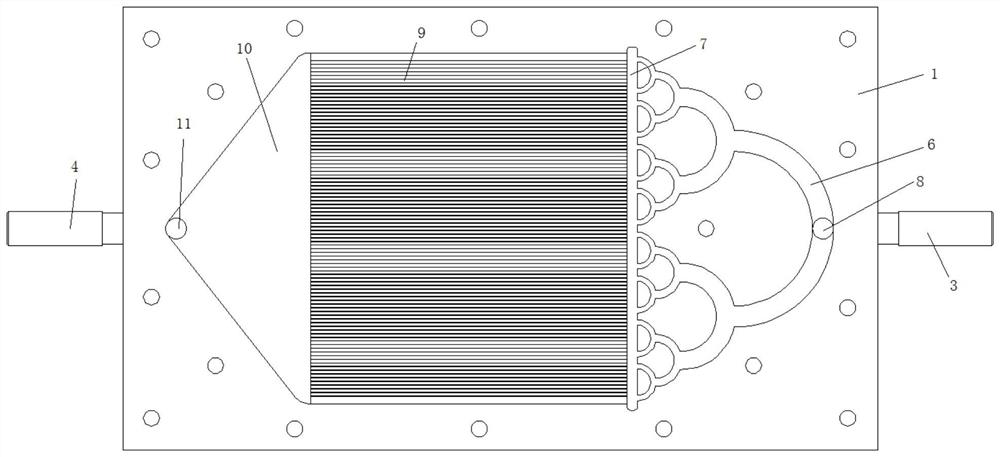

[0036] This embodiment provides a passive heat dissipation evaporator, such as Figure 1-3 As shown, it includes a plate body, which is made of heat-conducting material. The plate body in this embodiment is made of copper material, which improves the heat-conducting capacity of the entire evaporator, and adopts a flat-plate structure, which is convenient for direct installation on electronic components. device or chip surface.

[0037] The plate body is assembled by the first plate part 1 and the second plate part 2, the lower surface of the first plate part is attached to the upper surface of the second plate part, and the first plate part and the second plate part are connected by a plurality of fixing bolts The whole constitutes the entire board body.

[0038] When the first plate part 1 and the second plate part 2 are connected, a sealant is applied between the first plate part 1 and the second plate part 2 to prevent the leakage of the cooling medium.

[0039] The lower...

Embodiment 2

[0059] This embodiment provides a passive cooling system, such as Figure 4 As shown, the passive heat dissipation evaporator described in Embodiment 1 is provided.

[0060] Specifically, the second inlet channel of the passive heat dissipation evaporator is connected to the outlet of the compensation chamber 13 through the liquid phase pipeline 12, the inlet of the compensation chamber 13 is connected to the outlet of the condenser 14 through the pipeline, and the inlet of the condenser 14 is connected through the gas phase pipeline. 15 is connected to the second flow channel part of the passive heat dissipation evaporator.

[0061] The installation height of the compensation chamber 13 is higher than that of the passive heat dissipation evaporator, and the installation height of the condenser 14 is higher than that of the compensation chamber 13 .

[0062] In this embodiment, as Figure 5-Figure 6 As shown, the compensation chamber 13 can adopt the structure of the compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com