Soaking plate and manufacturing and application method thereof

A technology of soaking plate and shell plate, applied in the field of heat dissipation, can solve the problems such as insufficient contact of the liquid absorbing core, reduction of working fluid return channels, reduction of capillary limit and boiling limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment one includes inventions one and two.

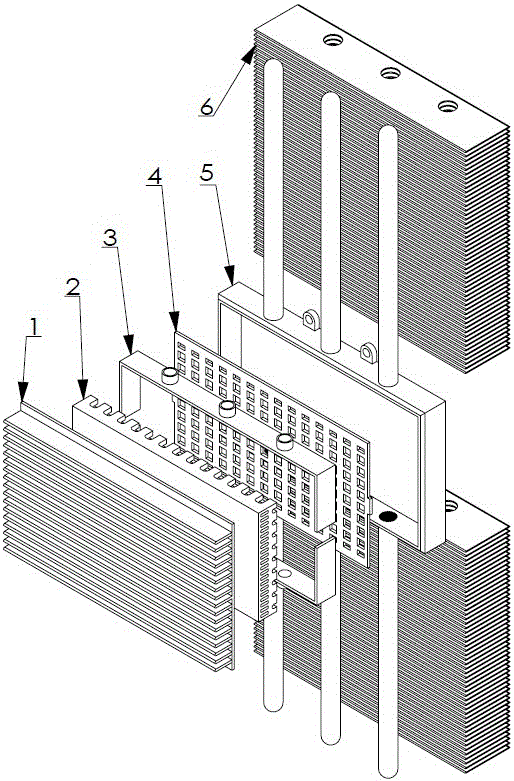

[0079] Such as figure 1 As shown in —14, Invention 2 is formed by combining Invention 1 with the second heat dissipation fin 6. The second heat dissipation fin 6 is made of aluminum metal sheet, and the edge of the metal profile can be formed into a streamlined edge structure 62 by grinding and other processes. , and then blanking, punching, forming holes 61, and finally combining a number of second heat dissipation fins through the buckle fin process.

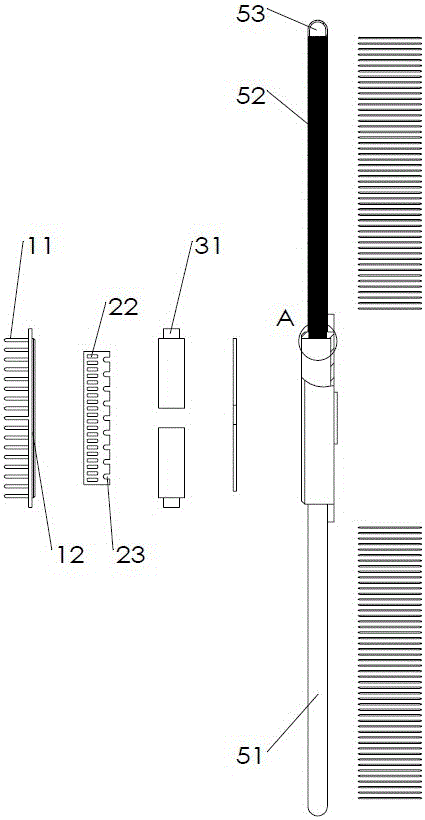

[0080] Invention 1 consists of an upper shell plate 1, a first capillary structure 2, a third capillary structure 3, a second capillary structure 4, and a lower shell plate 5, forming a closed vacuum chamber containing an appropriate amount of working fluid (not shown).

[0081] The upper shell 1 can obtain the first heat dissipation fins 11 and the boss 12 of the upper shell by using an aluminum extrusion process.

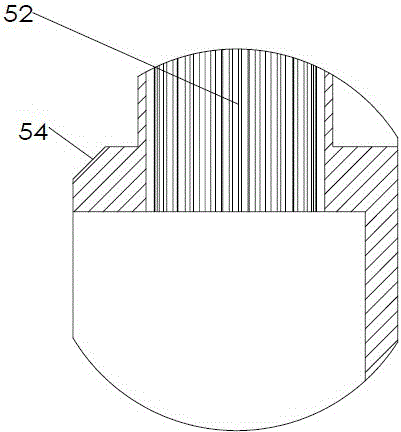

[0082] The main part of the lower shell 5 can be ma...

Embodiment 2

[0090] Embodiment 2 includes invention 3.

[0091] Input the shape, size, and material of inventions 1 and 2 into the computer, and manufacture them through a 3D printer, or set the first, second, and third capillary structures in the already-made lower shell plate 5 through a 3D printer, and then pass through the remaining The next step is to complete the production. It can also be manufactured in a vacuum environment to obtain related products without welds.

Embodiment 3

[0092] Embodiment three includes inventions four and five.

[0093] Such as Figure 15 As shown, the liquid metal 105 is sealed between the PCB board 104 , the chip 103 , the o-ring 102 , and the heat sink 101 . The o-ring 102 has the function of reducing the pressure between the heat sink 101 and the chip 103, and the function of reducing mechanical vibration, and preventing the entry of external air and foreign objects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com