Onboard control system of high-speed maglev train

A control system and technology for maglev trains, applied in the field of control systems between rails and trains, can solve problems such as the complexity of the synchronous linear motor control system, the difficulty of avoiding two-car collision accidents, and the restriction of the development of maglev trains. method and computing equipment, eliminating the need for intermediate transfer control links, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail now in conjunction with accompanying drawing.

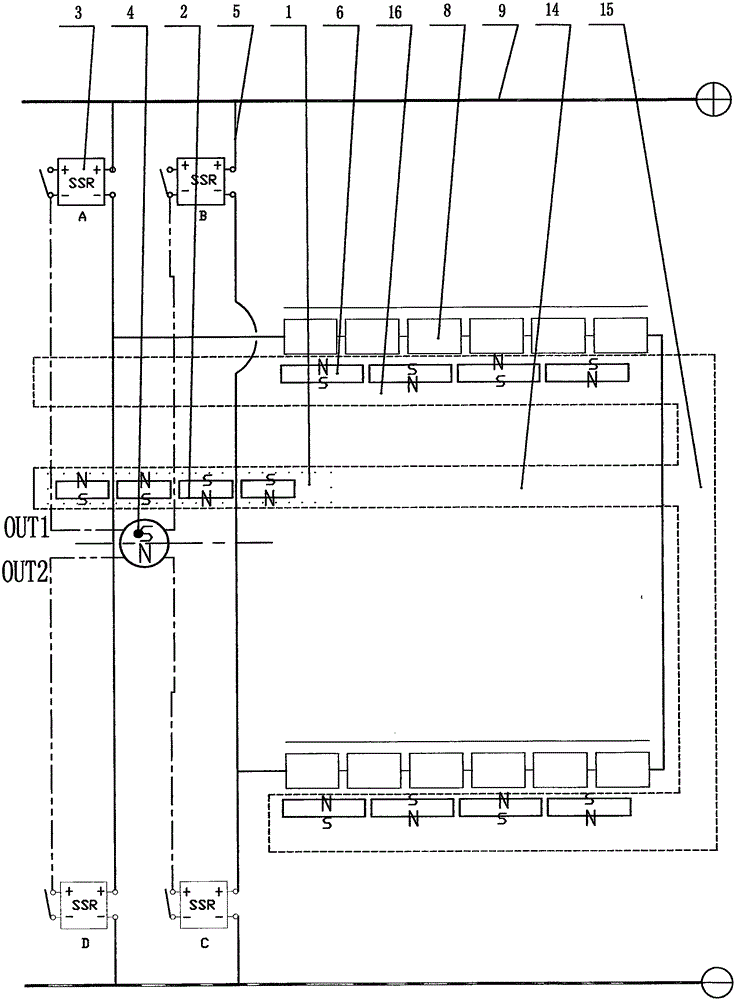

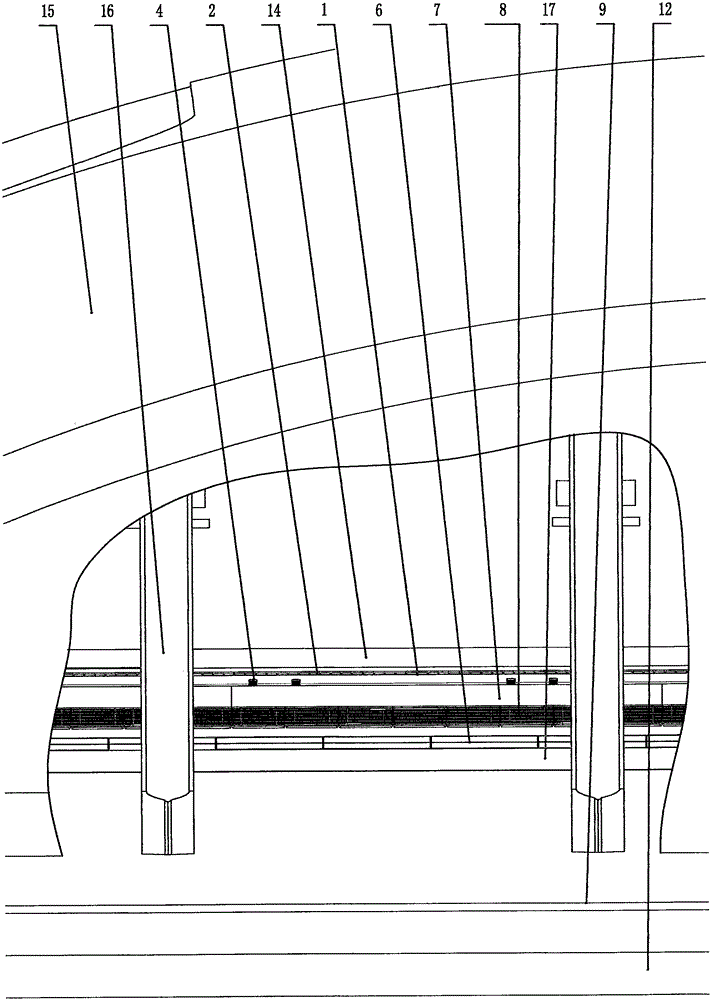

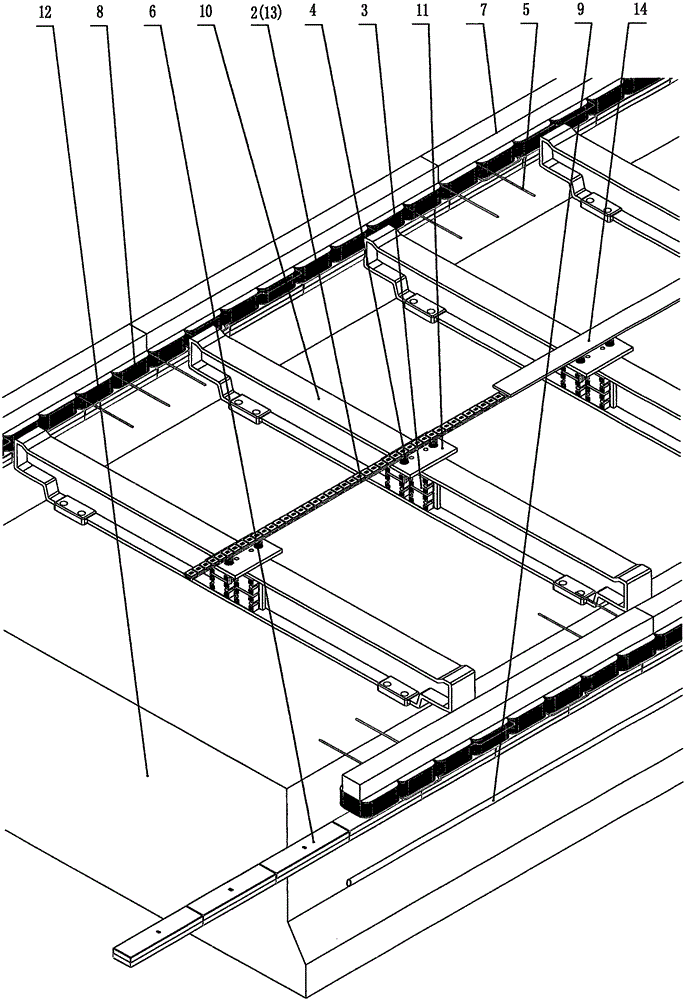

[0034] Such as figure 1 As shown, the working principle of the vehicle-mounted control system 1 of the present invention is disclosed. Main wires 9 are arranged on both sides of the track. The main wire 9 on one side is the positive pole of the power supply, and the main wire on one side is the negative pole of the power supply. The track is provided with a fixed drive coil 8, and the bottom of the drive coil 8 is provided with a traction permanent magnet 6 at a certain gap, and the traction permanent magnet 6 is fixedly connected to the bottom of the train, and the fixed drive coil 8 and the traction permanent magnet 6 constitute a linear motor. Each group of driving coils 8 is composed of several sub-coils, which are connected in series to form a group of driving coils 8, and the two ends of each group of driving coils 8 are connected with two solid state relays 3 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com