Vehicle engine room pipeline layout structure and vehicle

A technology for arranging structure and cabin, which is applied in the directions of vehicle components, circuits or fluid pipelines, transportation and packaging, etc., which can solve the problem that the engine room pipeline structure cannot be systematically arranged, the engine room pipeline structure layout is inconvenient, and the pipeline maintenance and replacement are difficult, etc. problems, to achieve the effect of easy maintenance and identification, easy layout positioning structure, easy layout and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

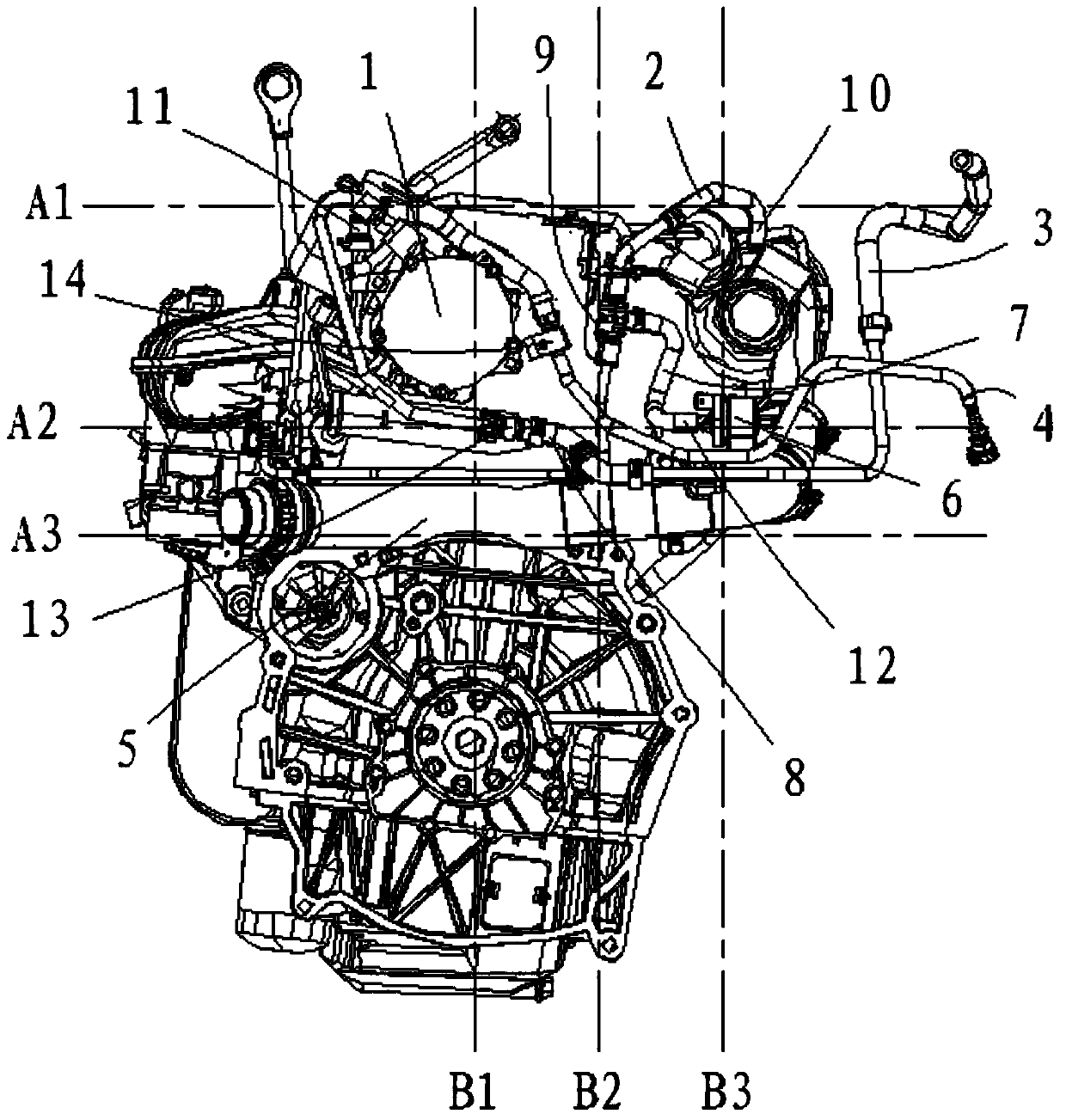

[0027] This embodiment relates to a pipeline arrangement structure in the engine room of a vehicle, such as figure 1 As shown in , it includes a desorption pipe assembly 2 , a vacuum booster pipe assembly 3 , an intercooler pipe assembly 5 and an oil inlet pipe assembly 4 respectively connected to the engine main body 1 . The pipeline layout structure of the vehicle cabin also includes a carbon canister solenoid valve 6 arranged in parallel on the desorption pipe assembly 2 , and an unshown air filter arranged on the engine main body 1 . In this embodiment, along the height direction of the vehicle, the connection point between the desorption pipe assembly 2 and the air filter is also figure 1 The second connection point 10, the connection point between the desorption tube assembly 2 and the canister solenoid valve 6 is the fourth connection point 12, the connection point between the vacuum booster tube assembly 3 and the engine main body 1 is the fifth connection point 13, a...

Embodiment 2

[0035] This embodiment relates to a vehicle, which includes an engine main body arranged in the engine room, a desorption pipe assembly connected to the engine main body, a vacuum booster pipe assembly, an intercooler pipe assembly, and an oil inlet pipe assembly; The canister solenoid valve installed in parallel on the desorption pipe assembly, and the air filter installed on the engine main body, and the desorption pipe assembly, vacuum booster pipe assembly, intercooler pipe assembly, oil inlet pipe assembly and Between the carbon canister solenoid valve and the air filter, the vehicle cabin pipeline layout structure as described in Embodiment 1 is arranged at the engine main body.

[0036] In the vehicle of this embodiment, through the structural arrangement between the assemblies as described in Embodiment 1, the pipelines of each assembly can be arranged in sections, which is convenient for arranging the positioning structure, and also facilitates the later maintenance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com