Omnidirectional moving chassis and leveling method thereof

An omnidirectional movement and chassis technology, applied in the direction of motor vehicles, suspensions, vehicle springs, etc., can solve the problems of inconsistent program output paths, inability to achieve precise movement, and unequal combined speed direction, etc., achieving good effects and low cost , The effect of the same friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

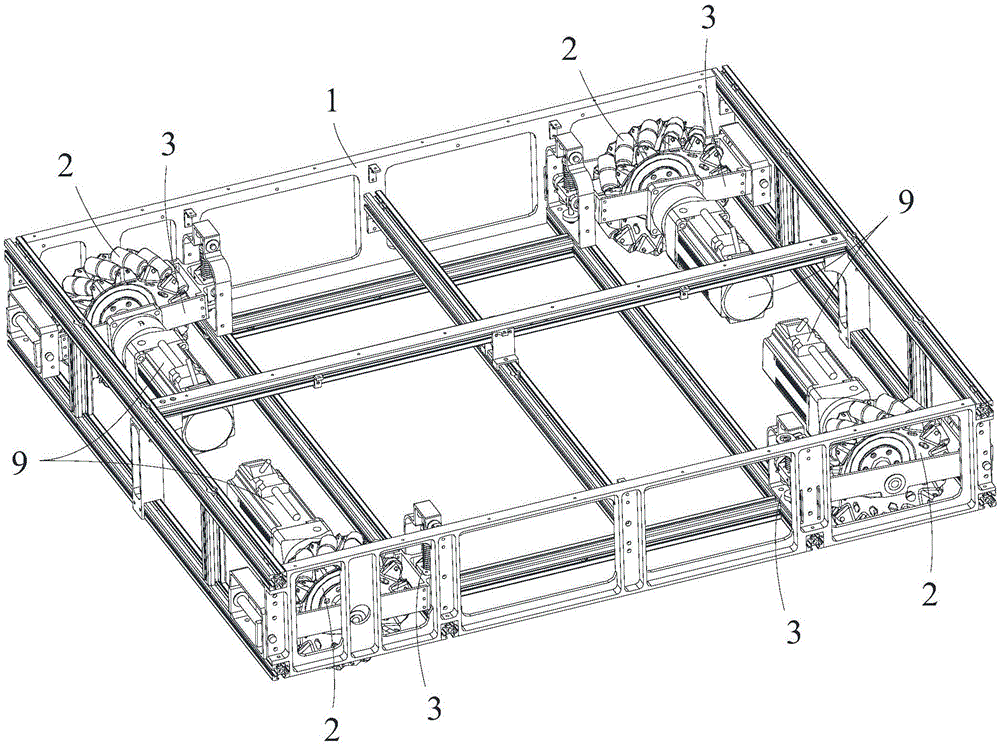

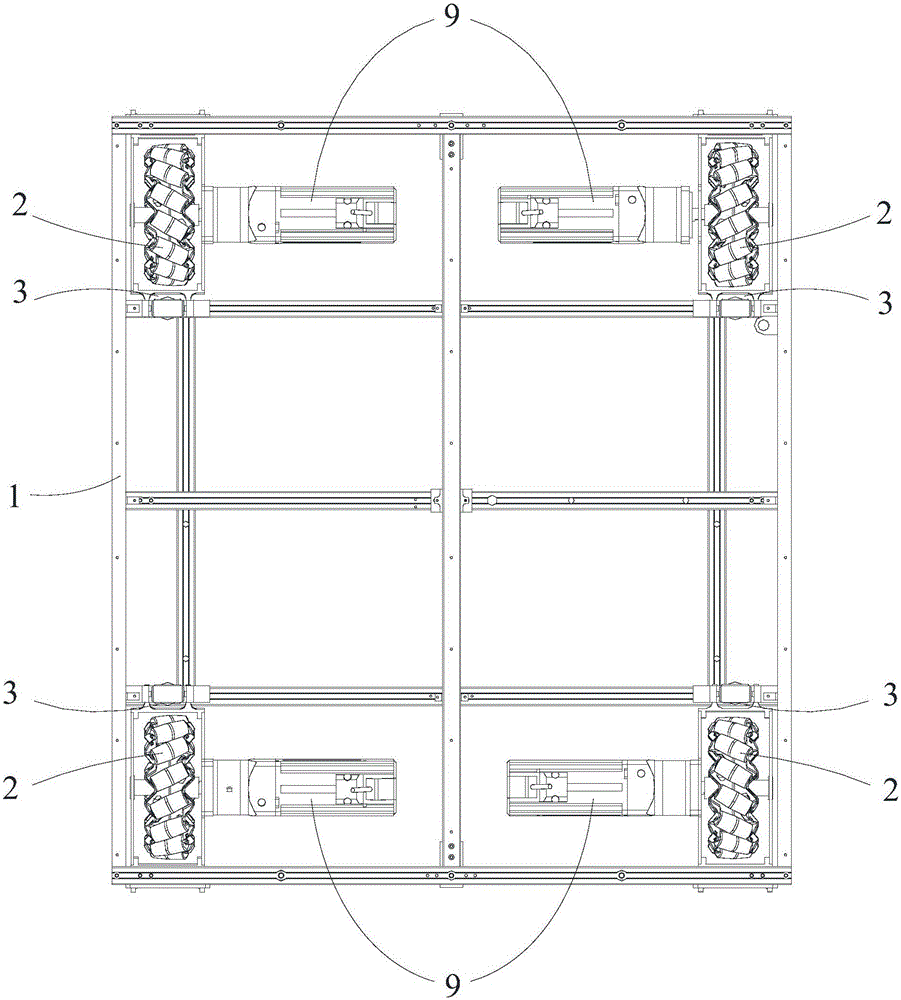

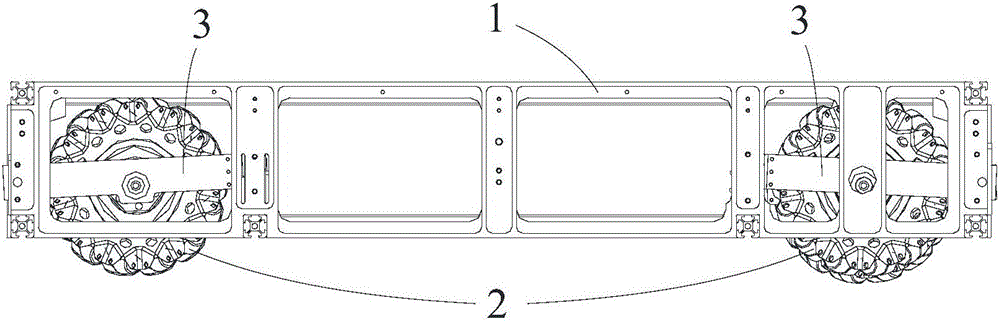

[0048] Such as Figure 1-5 As shown, the omnidirectional mobile chassis of the present invention includes a frame 1, a drive system and a control system.

[0049] Such as Figure 1-3 As shown, the frame 1 is a cuboid frame structure, and its four bottom corners are respectively provided with an adjustment part 3, a bracket 4 and an omnidirectional wheel 2, and each omnidirectional wheel 2 is connected to the corresponding bracket 4. Each of the adjustment parts 3 includes a bolt 5, a nut 51, a nut 2 52, a slider 6, a spring 7 and a buffer pad 8, such as Figure 5 As shown, the bolt 5 is a stepped bolt, one end of which is provided with a shaft hole, the shaft hole is adapted to the shaft, the shaft is connected to the frame 1, and the bolt body at one end of the shaft hole is provided with an M6 outer thread, the middle is a smooth section, its diameter is 5mm, and the other end of the bolt body is provided with an M5 external thread, the nut one 51 is an M6 nut, the nut two...

Embodiment 2

[0055] Such as Figure 1-6 As shown, the leveling method of the omnidirectional mobile chassis of the present invention, the application of the omnidirectional mobile chassis as described in Embodiment 1 includes the following steps:

[0056] A, an electronic scale is set under each of the omnidirectional wheels 2;

[0057] B. Screw the nut one 51 on each of the adjustment parts 3 to make the corresponding omnidirectional wheel 2 move vertically up and down;

[0058] C. Read the positive pressure value of the corresponding omnidirectional wheel 2 on each of the electronic scales;

[0059] D. Adjust each nut one 51 until all positive pressure values are consistent or within the allowable error range;

[0060] E. Make the chassis suspended, all the omnidirectional wheels 2 off the ground, each of the springs 7 returns to the free state length, screw the nut 2 52 on each of the adjustment parts 3, and drive the buffer pad 8 to move, so that the buffer pad 8 contacts the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com