Hot air curtain assisted evaporation system

An auxiliary evaporation and hot air technology, which is applied in the direction of special treatment targets, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problems of small vaporization, non-vaporization, explosion of chlorine bottles, etc., to ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

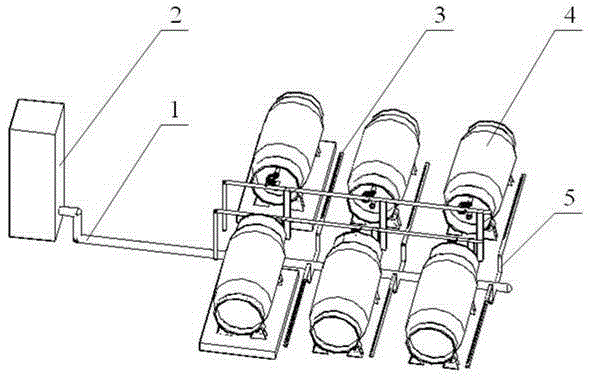

[0018] refer to figure 1 , a hot air curtain auxiliary evaporation system, including a hot air curtain machine 2, a temperature control system, a neutralization device and a chlorine addition system, the neutralization device is provided with a chlorine gas detection probe and a control system, and the outlet of the hot air curtain machine 2 The tuyere is provided with a main pipeline 1, the main pipeline 1 is provided with a multi-component pipeline 5, the quantity of the sub-pipes 5 is equal to the quantity of the chlorine bottles 4 provided in the chlorination system, and each sub-pipe 5 is provided with On one side of the corresponding chlorine bottle 4, the sub-pipe 5 is provided with an air outlet 3, and the air outlet 3 is arranged facing the bottle body of the chlorine bottle 4. On the temperature control system and the neutralization device All cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com