Tape casting device

A technology of a working platform and a storage tank is applied in the field of casting devices for the production of zirconia substrates, and can solve the problems of uneven thickness, stripes on the surface of blanks, and inability to meet the high-efficiency and high-quality production of zirconia substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

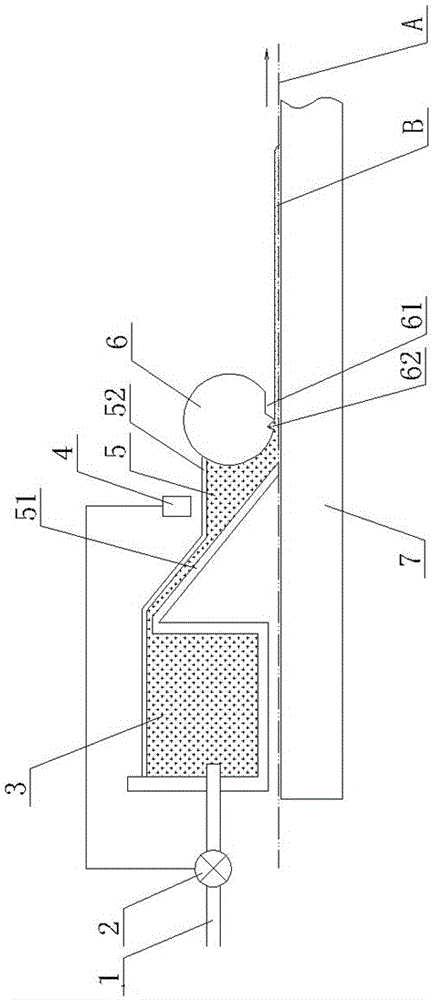

[0011] As shown in the figure, the casting device of the present invention includes a working platform 7 and a film belt A that is drawn and transported against the horizontal surface of the working platform. A storage tank 5 is provided above the film belt A. The storage tank 5 is formed by the material tank. The side plates (front side plate 51, left and right side plates 52) and the scraper 6 are enclosed together. The scraper 6 is located on the rear side of the storage tank 5. The left and right sides of the scraper 6 are closely abutting the left and right side plates 52. The front side plates 51, left and right The bottom surface of the side plate 52 and the film tape A are in close contact with each other, and a casting gap is left between the bottom of the scraper 6 and the film tape A. The scraper 6 has a circular arc bottom. , The rear knife groove forms a double-head structure of the scraper, the front knife groove 62 is a triangular groove, and the rear knife groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com