A modified epoxy resin anti-seepage plugging grouting method for concrete in alpine regions

An epoxy resin and concrete technology, which is applied in the field of modified epoxy resin anti-seepage plugging grout for concrete in alpine regions, can solve the problems of frequent thermal expansion and contraction, high initial viscosity, and insufficient construction operation time, etc., to achieve Meet the needs of engineering applications, reduce the initial viscosity, and ensure the effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

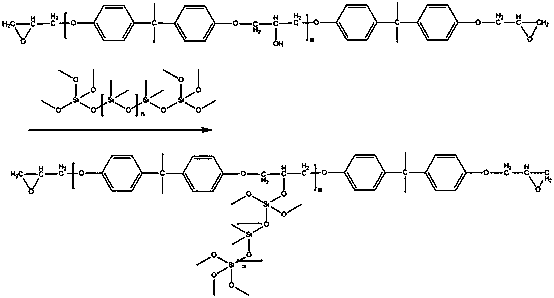

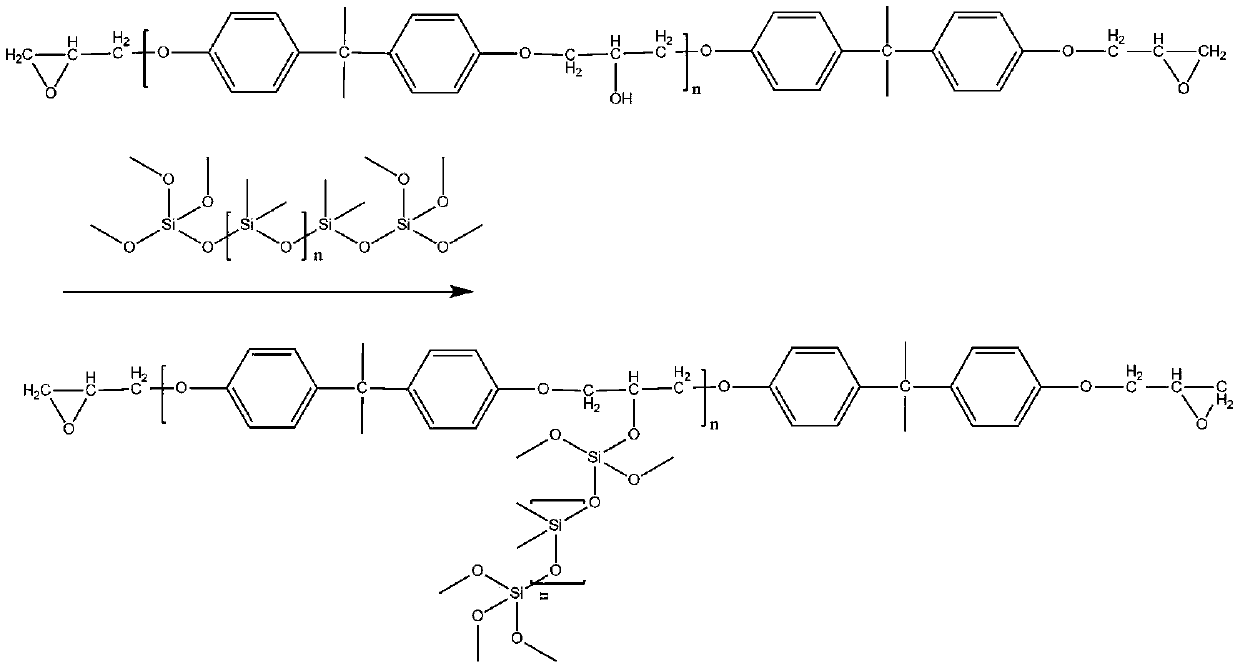

Method used

Image

Examples

Embodiment 1

[0033] In a 250 mL four-neck flask, add 10 g of trimethoxy-terminated silicone oil PDMS (Mn=10000), 90 g of epoxy resin E-44, add 3 drops of catalyst dibutyltin dilaurate, and heat under reflux at 120 °C for 5 h Afterwards, it is distilled under reduced pressure until no more bubbles are generated, and the residue in the kettle is the modified epoxy resin. Take this epoxy resin 40 g, furfural acetone reactive diluent 45 g, curing agent N-(β-aminoethyl)-γ-aminopropyl trimethoxysilane hydrolyzate 13 g and accelerator DMP-30 2 g, The grouting material is obtained by stirring evenly at 0 °C, and the basic properties of the grouting material are shown in Table 1.

Embodiment 2

[0035] In a 250 mL four-neck flask, add 10 g of triethoxy-terminated silicone oil PDMS (Mn=10000), 90 g of epoxy resin E-51, add 3 drops of catalyst dibutyltin dilaurate, and heat under reflux at 120 °C for 5 After h, vacuum distillation was performed until no more bubbles were generated, and the residue in the kettle was the modified epoxy resin. Take the epoxy resin 30 g, furfural acetone reactive diluent 50 g, curing agent N-(β-aminoethyl)-γ-aminopropyl triethoxysilane hydrolyzate 18 g and accelerator DMP-30 2 g , the grouting material is obtained by stirring evenly at 0 °C, and the basic properties of the grouting material are shown in Table 1.

Embodiment 3

[0037] In a 250 mL four-neck flask, add 10 g of trimethoxy-terminated silicone oil PDMS (Mn=10000), 90 g of epoxy resin E-44, add 3 drops of catalyst dibutyltin dilaurate, and heat under reflux at 120 °C for 5 h. , distilled under reduced pressure until no more bubbles are produced, and the residue in the kettle is the modified epoxy resin. Take the epoxy resin 40 g, furfural acetone reactive diluent 38 g, curing agent N-(β-aminoethyl)-γ-aminopropyl triethoxysilane hydrolyzate 20 g and accelerator DMP-30 2 g , the grouting material is obtained by stirring evenly at 0 °C, and the basic properties of the grouting material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com