A kind of oxygen carrier for chemical looping combustion, its preparation method and application

A chemical looping combustion and oxygen carrier technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low dispersion of metal oxides and high reaction temperature of chemical chain oxygen carriers , to achieve the effects of lower temperature, high low temperature activity, and strong ion exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

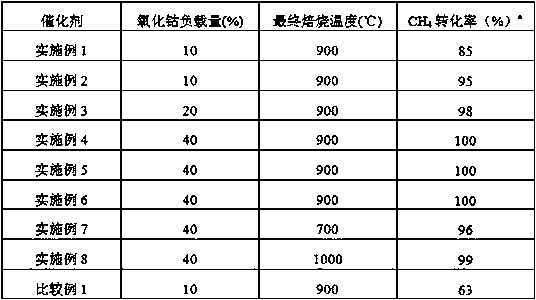

Examples

Embodiment 1

[0027] Weigh 62g 60~80 mesh SiO 2 , put into a beaker, add 200mL of distilled water, and start stirring. Weigh 29.6gCa(NO 3 ) 2 ﹒ 4H 2 O was dissolved in 125mL of absolute ethanol, 19.8g of diammonium hydrogen phosphate was weighed and dissolved in 75mL of deionized water, the two solutions were mixed, added dropwise to silicon oxide water, and the pH value was adjusted to 9 with ammonia water, and then placed in a water bath at 30°C Stir for 1h, age at 30°C for 24h, then filter with suction, wash with distilled water for 3 times, then dry at 110°C for 24h, and bake at 900°C for 6 hours to obtain the carrier HAp / SiO 2 .

[0028] Weigh the measured amount of cobalt nitrate, dissolve it in an appropriate amount of deionized water, and impregnate the measured amount of HAp / SiO 2 overnight, then dried in a 120°C drying oven for 12h, and calcined in a 900°C muffle furnace for 4h to obtain Co 2 o 3 / HAp / SiO 2 Oxygen carrier, where Co 2 o 3 The mass content is 10%, the mas...

Embodiment 2

[0030] Weigh 62g 60~80 mesh SiO 2 , put into a beaker, add 200mL of distilled water, and start stirring. Weigh 29.6gCa(NO 3 ) 2 ﹒ 4H 2 O was dissolved in 125mL of absolute ethanol, 49.5g of diammonium hydrogen phosphate was weighed and dissolved in 75mL of deionized water, the two solutions were mixed, added dropwise to silicon oxide water, and the pH value was adjusted to 9 with ammonia water, and then placed in a water bath at 30°C Stir for 1h, age at 30°C for 24h, then filter with suction, wash with distilled water for 3 times, then dry at 110°C for 24h, and bake at 900°C for 6 hours to obtain the carrier HAp / SiO 2 .

[0031] Weigh the measured amount of cobalt nitrate, dissolve it in an appropriate amount of deionized water, and impregnate the measured amount of HAp / SiO 2 overnight, then dried in a 120°C drying oven for 12h, and calcined in a 900°C muffle furnace for 4h to obtain Co 2 o 3 / HAp / SiO 2 Oxygen carrier, where Co 2 o 3 The mass content is 10%, the mas...

Embodiment 3

[0033] Weigh 62g 60~80 mesh SiO 2 , put into a beaker, add 200mL of distilled water, and start stirring. Weigh 59.2gCa(NO 3 ) 2 ﹒ 4H 2 O was dissolved in 125mL of absolute ethanol, weighed 19.8g of diammonium hydrogen phosphate and dissolved in 75mL of deionized water, mixed the two solutions, added dropwise to silicon oxide water, adjusted the pH value to 9 with ammonia water, and then placed in a water bath at 30°C Stir for 1h, age at 30°C for 24h, then filter with suction, wash with distilled water for 3 times, then dry at 110°C for 24h, and bake at 900°C for 6 hours to obtain the carrier HAp / SiO 2 .

[0034] Weigh the measured amount of cobalt nitrate, dissolve it in an appropriate amount of deionized water, and impregnate the measured amount of HAp / SiO 2 overnight, then dried in a 120°C drying oven for 12h, and calcined in a 900°C muffle furnace for 4h to obtain Co 2 o 3 / HAp / SiO 2 Oxygen carrier, where Co 2 o 3 The mass content is 20%, the mass content of HAp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com