Novel lubricating oil and preparation method thereof

A lubricating oil, a new type of technology, applied in the field of lubricating oil, can solve the problems of anti-oxidation, anti-corrosion and extreme pressure resistance, general high anti-wear effect, unsatisfactory low-temperature fluidity and high-temperature resistance, and poor permeability. Achieve good lubricating effect, good adaptability to low temperature and high temperature performance, and improve permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

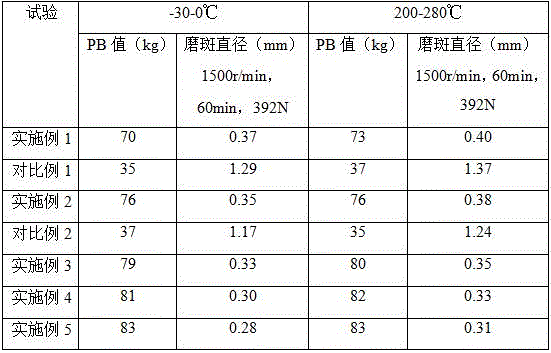

Examples

Embodiment 1

[0021] S1: Mix 50 parts of rosehip oil, 60 parts of grape seed oil, 10 parts of ethyl acetylacetonate, 7 parts of guaiazulene and 9 parts of sebacic acid, heat to 40°C, and stir at a speed of 600r / min React for 15 minutes;

[0022] S2: Add 8 parts of ethyl 2-oxocyclopentenecarboxylate, 6 parts of cinnamic acid, 5 parts of 4-fluoroacetanilide and 4 parts of dichloropyridinol to step S1, and continue to raise the temperature to 70°C, Stir the reaction at a rate of 800r / min for 20min;

[0023] S3: Add 8 parts of dioleic acid phosphite, 12 parts of vanillyl butyl ether, 3 parts of 2,3,4-trihydroxybenzophenone and 9 parts of diphenperidine into step S2, and after ultrasonic treatment for 5 minutes , raise the temperature to 90° C., stir and react at a rate of 1000 r / min for 1 h; the lubricating oil can be obtained after the reaction is cooled.

Embodiment 2

[0029] S1: Mix 70 parts of rosehip oil, 70 parts of grape seed oil, 15 parts of ethyl acetylacetonate, 10 parts of guaiazulene and 13 parts of sebacic acid, heat to 60°C, and stir at a speed of 600r / min React for 25 minutes;

[0030] S2: Add 12 parts of ethyl 2-oxocyclopentenecarboxylate, 10 parts of cinnamic acid, 9 parts of 4-fluoroacetanilide and 8 parts of dichloropyridinol to step S1, and continue to raise the temperature to 80°C. Stir the reaction at a rate of 800r / min for 25min;

[0031] S3: Add 15 parts of dioleic acid phosphite, 16 parts of vanillyl butyl ether, 7 parts of 2,3,4-trihydroxybenzophenone and 13 parts of diphenperidine to step S2, after ultrasonic treatment for 10 minutes , raise the temperature to 100° C., stir and react at a speed of 1000 r / min for 2 h; the lubricating oil can be obtained after the reaction is cooled.

Embodiment 3

[0037] S1: Mix 60 parts of rosehip oil, 65 parts of grape seed oil, 12 parts of ethyl acetylacetonate, 7 parts of guaiazulene and 10 parts of sebacic acid, heat to 40°C, and stir at a speed of 600r / min React for 15 minutes;

[0038] S2: Add 9 parts of ethyl 2-oxocyclopentenecarboxylate, 7 parts of cinnamic acid, 6 parts of 4-fluoroacetanilide and 5 parts of dichloropyridinol to step S1, and continue to raise the temperature to 70°C, Stir the reaction at a rate of 800r / min for 20min;

[0039] S3: Add 9 parts of dioleic acid phosphite, 13 parts of vanillyl butyl ether, 4 parts of 2,3,4-trihydroxybenzophenone and 10 parts of diphenperidine into step S2, after ultrasonic treatment for 5 minutes , raise the temperature to 90° C., stir and react at a rate of 1000 r / min for 1 h; the lubricating oil can be obtained after the reaction is cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com