Anti-corrosion nodule-free sink roll

A sinking roller and anti-corrosion technology, which is applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve the problems of poor transportation of aluminum-zinc-iron alloy elements and easy nodulation, etc., to improve wear resistance , reduce nodulation, reduce the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

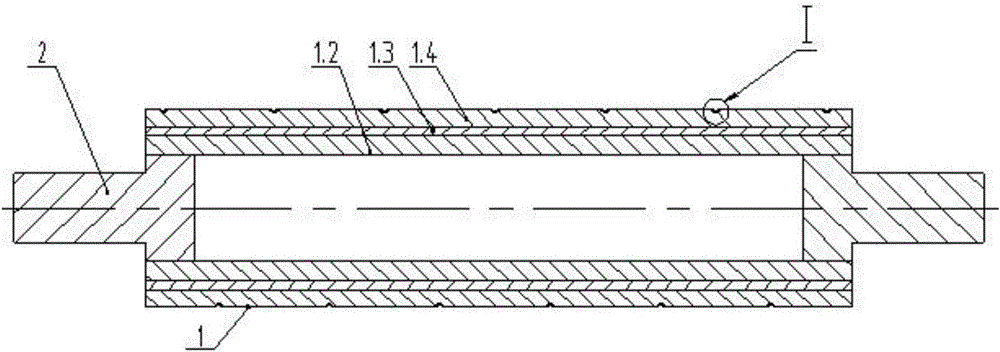

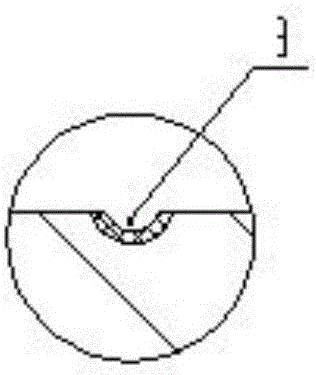

[0014] The anti-corrosion and no-nodulation sinking roll shown in the accompanying drawings includes a cylindrical roll body 1 and a roll shaft 2 connected to both ends of the roll body 1; the roll body 1 includes alloy sleeves 1.2, metal Ceramic sleeve 1.3, sealing agent layer 1.4, the surface of the sealing agent layer 1.4 is provided with a spiral groove 3; the bottom of the spiral groove 3 is arc-shaped; the surface of the spiral groove 3 is provided with a wear-resistant coating. The grinding coating is a layer of tungsten carbide alloy sprayed on the surface of the spiral groove 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com