A kind of graphene composite metal oxide electrode and preparation method and application thereof

A graphene composite and composite electrode technology, which is applied in chemical instruments and methods, electrodes, electrode shapes/types, etc., can solve problems such as easy peeling off of the coating, influence on the electrolytic system, and graphene drift, so as to improve the binding force and prepare The effect of simple process and stable carbon skeleton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

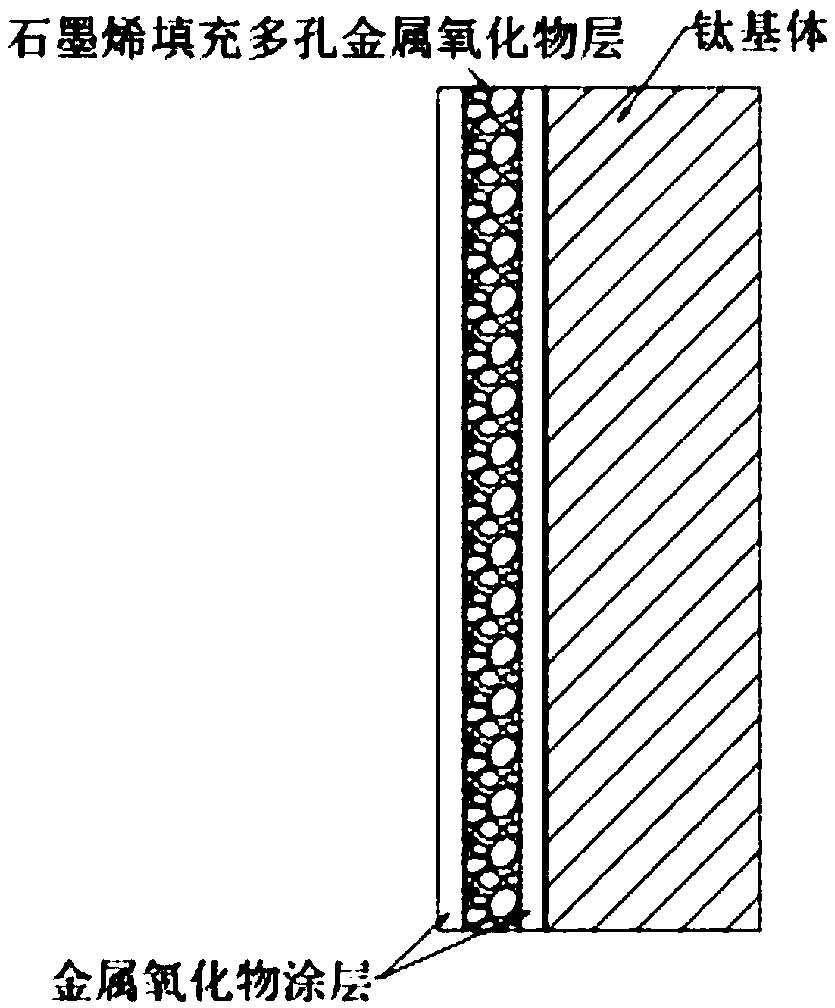

[0036] The graphene composite Ru-Ir-Sn metal oxide electrode prepared in this embodiment comprises a titanium substrate and a composite coating positioned on the surface of the titanium substrate, and the composite coating is coated with a lower metal oxide layer, a graphite layer from bottom to top, and The ene-filled porous metal oxide layer and the upper metal oxide layer.

[0037] The specific preparation methods include:

[0038] (1) Select an industrial-grade titanium plate with a titanium alloy grade of TA2 and a thickness of 2mm, cut it into a rectangle of 80×20×2mm, perform sandblasting, etch and clean the surface with oxalic acid to remove the oxide layer on the surface;

[0039] (2) with RuCl 3 ·xH 2 O, H 2 IrCl 6 and SnCl 4 ·5H 2 The n-butanol mixed solution of O is the precursor, in which the molar ratio of Ru, Ir and Sn is 17:23:60, diluted with n-butanol so that the total concentration of metal ions is 0.6mol / L, and stirred evenly to obtain metal oxide pr...

Embodiment 2

[0051] The graphene composite metal oxide electrode network prepared in this embodiment comprises a titanium substrate and a composite coating positioned on the surface of the titanium substrate, and the composite coating is sequentially coated with a lower metal oxide layer and a graphene-filled porous metal from bottom to top. oxide layer and upper metal oxide layer. The specific preparation methods include:

[0052] (1) Select an industrial-grade titanium plate with a titanium alloy grade of TA2 and a thickness of 2mm, cut it into a rectangle of 80×20×2mm, perform sandblasting, etch and clean the surface with oxalic acid to remove the oxide layer on the surface;

[0053] (2) with RuCl 3 ·xH 2 O, H 2 IrCl 6 , SnCl 4 ·5H 2 The n-butanol mixed solution of O and tetrabutyl titanate is the precursor, in which the molar ratio of Ru, Ir, Sn and Ti is 36:4:20:40, diluted with dilute hydrochloric acid so that the total concentration of metal ions is 1.6 mol / L, stir evenly to ...

Embodiment 3

[0065] The graphene composite Ru-Ir-Sn metal oxide electrode prepared in this embodiment comprises a titanium substrate and a composite coating positioned on the surface of the titanium substrate, and the composite coating is coated with a lower metal oxide layer, a graphite layer from bottom to top, and The ene-filled porous metal oxide layer and the upper metal oxide layer. The specific preparation methods include:

[0066] (1) Select an industrial-grade titanium plate with a titanium alloy grade of TA2 and a thickness of 2mm, cut it into a rectangle of 80×20×2mm, perform sandblasting, etch and clean the surface with oxalic acid to remove the oxide layer on the surface;

[0067] (2) with RuCl 3 ·xH 2 O, H 2 IrCl 6 and SnCl 4 ·5H 2 The n-butanol mixed solution of O is the precursor, in which the molar ratio of Ru, Ir and Sn is 17:23:60, diluted with n-butanol so that the total concentration of metal ions is 0.6mol / L, and stirred evenly to obtain metal oxide precursor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com