Additive for reducing woody gas in cigarette bobbin, preparation method and application thereof

A technology for cigarette wrapping paper and additives, applied in special paper, non-fiber pulp addition, paper and other directions, can solve the problems of reducing the smoking quality of cigarettes and the entry of wood gas, and achieve the effect of reducing wood gas and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one, a kind of preparation method of the additive that reduces cigarette paper wood gas, concrete steps are as follows:

[0025] (1) Weigh raw materials according to the following parts by weight: 6 parts of tobacco absolute light components, 0.05 part of cedarwood oil, 0.004 part of guaiacol, 0.6 part of β-dihydrodamascone, and 1 part of dihydrocoumarin , 2 parts of ethyl vanillin, 90.346 parts of alcohol;

[0026] (2) Put the alcohol in the above-mentioned raw material formula into a blending tank, then accurately weigh the rest of the ingredients according to the above parts by weight and add them into the blending tank, stir for 2 hours, and let stand for 24 hours to obtain an additive for reducing cigarette paper woodiness.

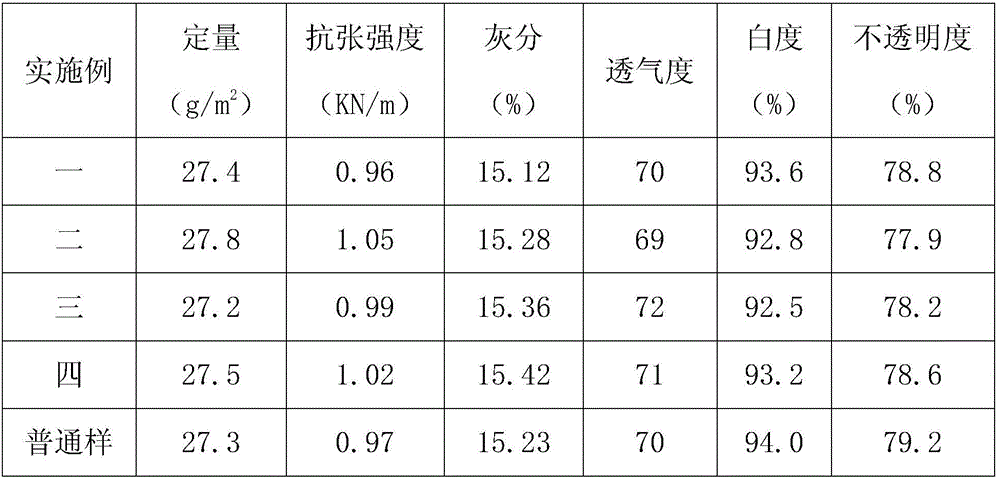

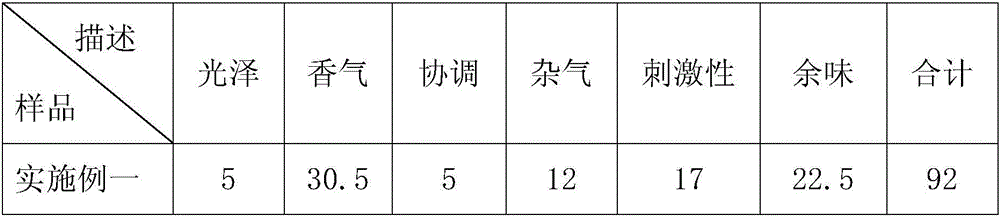

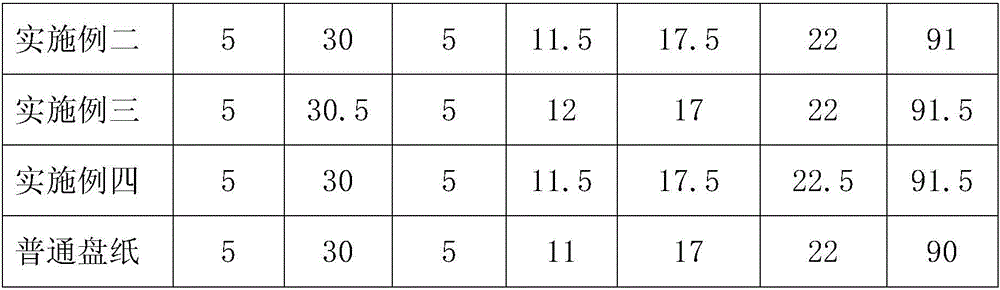

[0027] The cigarette wrapping paper wood gas-reducing additive prepared in Example 1 was sprayed on the surface of the cigarette wrapping paper at a weight ratio of 0.1% at the cigarette wrapping production additive spraying process...

Embodiment 2

[0028] Implementation example two, a method for preparing an additive for reducing cigarette paper wood gas, the specific steps are as follows:

[0029] (1) Weigh raw materials according to the following parts by weight: 8 parts of tobacco absolute light components, 0.06 parts of cedarwood oil, 0.005 parts of guaiacol, 0.5 parts of β-dihydrodamascone, and 2 parts of dihydrocoumarin , 3 parts of ethyl vanillin, 86.435 parts of alcohol;

[0030] (2) Put the alcohol in the above-mentioned raw material formula into a blending tank, then accurately weigh the rest of the ingredients according to the above parts by weight and add them into the blending tank, stir for 2 hours, and let stand for 24 hours to obtain an additive for reducing cigarette paper woodiness.

[0031] The cigarette wrapping paper wood gas-reducing additive prepared in Example 2 was sprayed on the surface of the cigarette wrapping paper at a weight ratio of 0.15% at the additive spraying process point of the cigar...

Embodiment 3

[0032] Embodiment three, a kind of preparation method of the additive that reduces cigarette paper wood gas, concrete steps are as follows:

[0033] (1) Weigh the raw materials according to the following parts by weight: 7 parts of tobacco absolute light components, 0.07 parts of cedarwood oil, 0.008 parts of guaiacol, 0.3 parts of β-dihydrodamascone, and 5 parts of dihydrocoumarin , 2 parts of ethyl vanillin, 85.622 parts of alcohol;

[0034] (2) Put the alcohol in the above-mentioned raw material formula into a blending tank, then accurately weigh the rest of the ingredients according to the above parts by weight and add them into the blending tank, stir for 3 hours, and let stand for 48 hours to obtain an additive for reducing cigarette paper woodiness.

[0035] The cigarette wrapping paper wood gas-reducing additive prepared in Example 3 was sprayed on the surface of the cigarette wrapping paper at a weight ratio of 0.5% at the cigarette wrapping production additive sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com