Reinforced concrete column beam anti-shock joint

A reinforced concrete, column beam technology, applied in earthquake resistance, building types, buildings, etc., can solve problems such as overall structural failure, vulnerable column ends, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

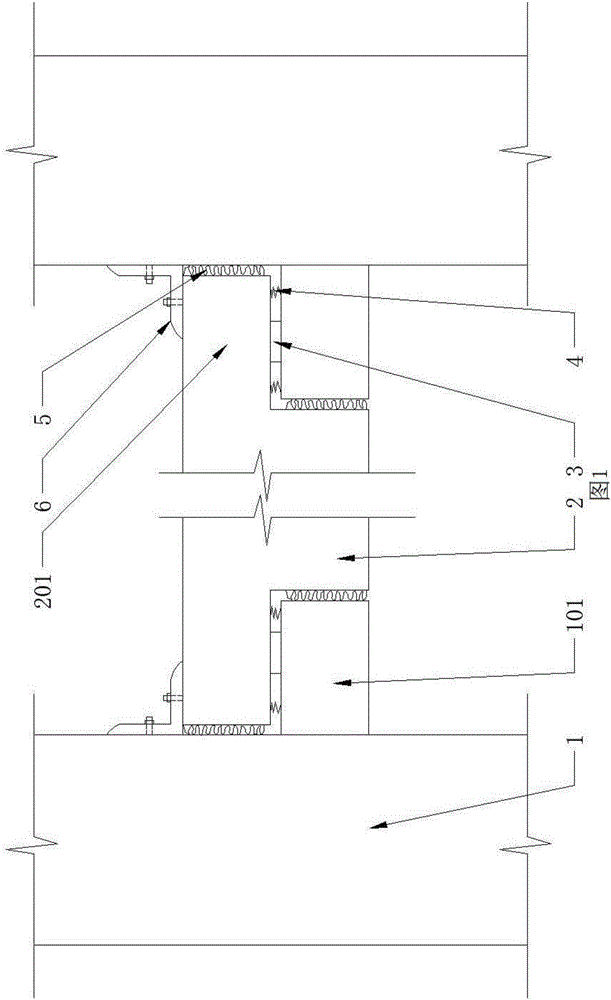

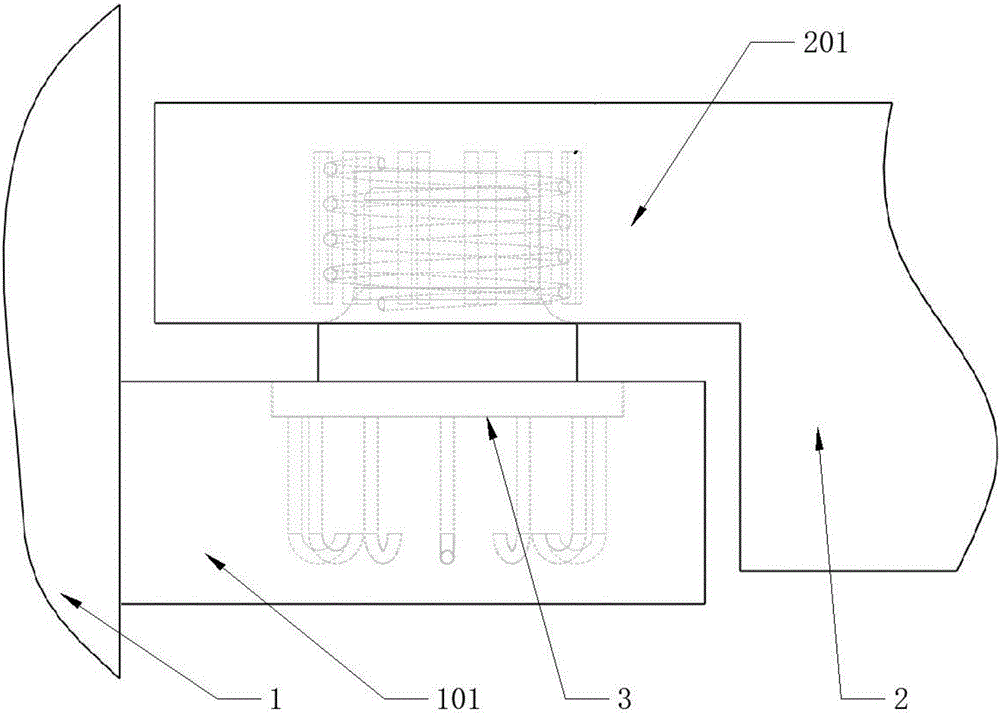

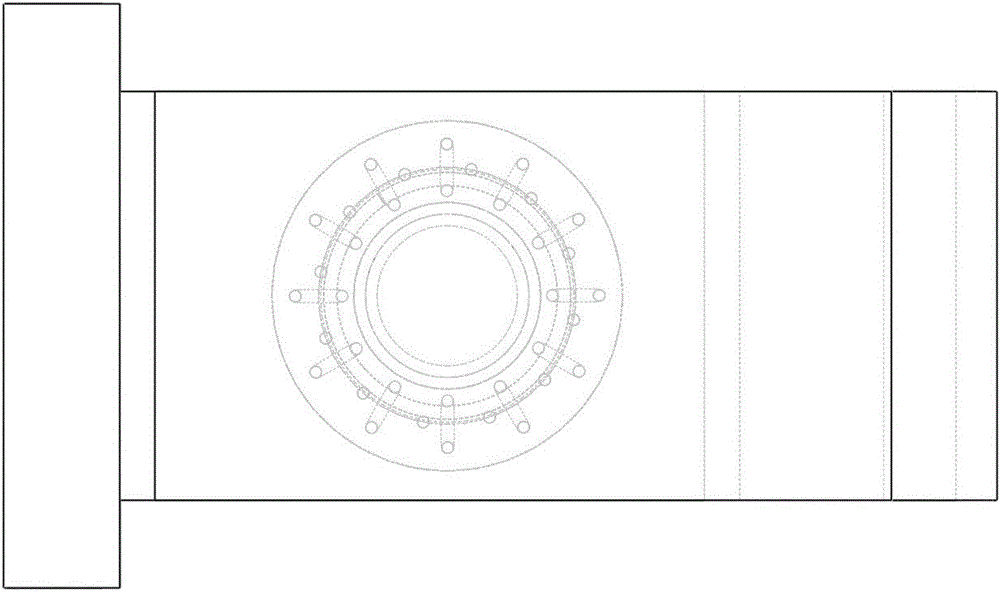

[0029] The present invention will be further explained below in conjunction with the drawings:

[0030] Such as Figure 1 to Figure 11 As shown, the reinforced concrete column beam seismic joint of the present invention includes a frame column 1, the frame column 1 extends outward to form a corbel 101, and the two ends of the frame beam 2 between the frame columns 1 extend outward to form a The protrusion 201 that matches the corbel 101, the protrusion 201 is provided with a limiting hole 8, and the limiting hole 8 is matched with the limiting platform 3 provided on the corbel 101; preferably, the limiting hole 8 The position table 3 includes a limit post 304 that matches with the limit hole 8. An inner corner 303 that matches the outer corner 801 is arranged between the limit post 304 and the base 302, and the bottom of the base 302 is fixedly connected There are multiple hooked steel bars 301; there is ample space for rotation between the top of the limit post 304 and the limi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com