Dry type connected concrete shear wall and dry type wall connecting method

A concrete shear wall and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low production efficiency of housing construction technology, inability to adapt to the rigid demand of housing, and high labor intensity of workers, so as to improve the efficiency of industrialization. , Superior seismic performance, the effect of reducing resource and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

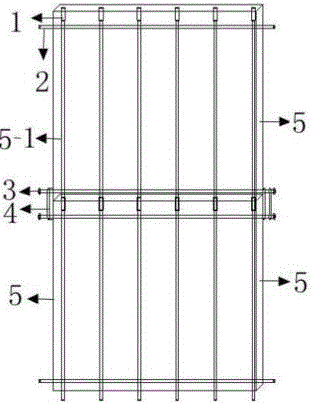

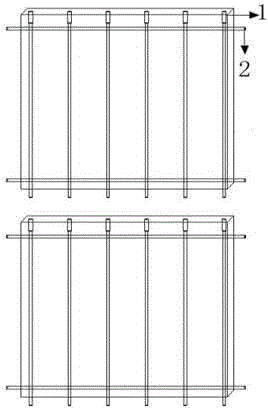

[0028] The following combination Figure 1-5 The technical scheme of the present invention is described in detail:

[0029] A dry-connected concrete shear wall, the prefabricated concrete shear wall 5 is vertically uniformly provided with vertical steel bars 5-1, and the upper and lower sides of the precast concrete shear wall 5 are horizontally provided with anchor steel bars 2 and vertical steel bars 5 -1 is connected with the anchoring reinforcement 2 by welding; the vertical reinforcement 5-1 of the adjacent precast concrete shear wall 5 is connected with the sleeve 1 at its alignment; the two ends of the metal connector 4 are respectively provided with round holes 4- 1. The two ends of the two anchor bars 2 at the alignment connection of the adjacent precast concrete shear walls 5 are aligned and connected through the round holes 4-1 of the metal connector 4; The connecting piece 4 is fastened to both ends of the anchoring steel bar 2; the diameter of the sleeve 1 is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com