A shaped plate steel bar arranging method

A technology of steel bars and shaped plates, applied in the direction of structural elements, building components, ceramic molding machines, etc., can solve the problems of not meeting the design requirements, achieve the effect of less varieties and specifications, easy to understand, and reduce the use of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

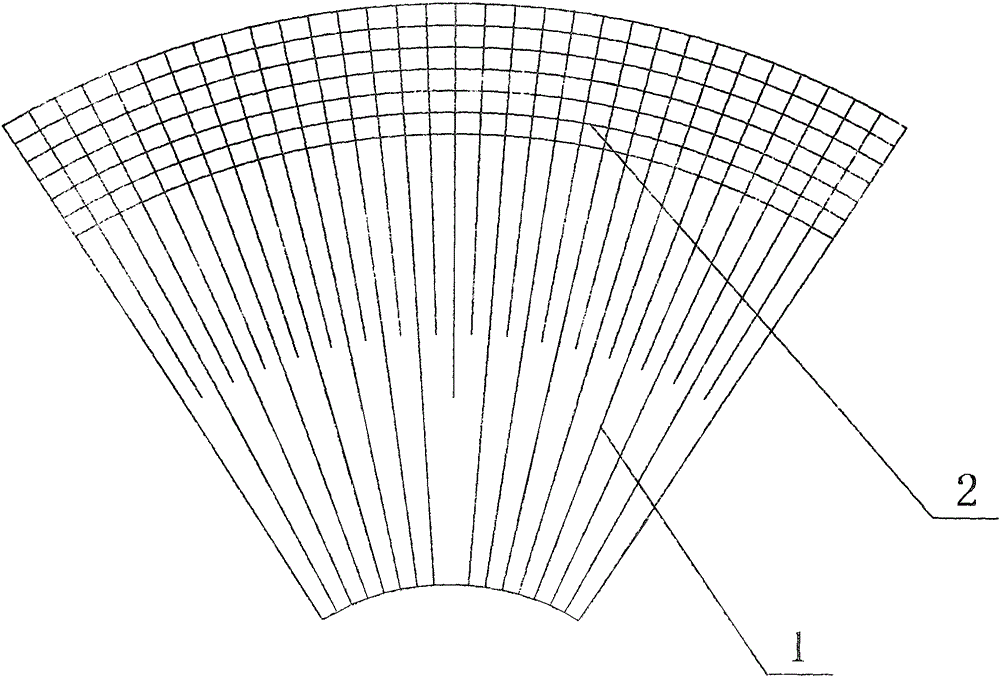

[0013] Such as figure 1 As shown, a method for arranging steel bars in a shaped plate, the steps are as follows:

[0014] Step 1. Steel bar classification: Divide the steel bars into radial steel bars 1 and circumferential steel bars 2. The principle is that the radial steel bars 1 are radially distributed from the center of the circle, and the circumferential steel bars 2 are arranged around the center of the circle, perpendicular to the radial steel bars.

[0015] Step 2. Determination of the shape plate: determine whether the shape plate is a one-way slab or a two-way slab. If it is a two-way slab, radial steel bars or circumferential steel bars can be placed underneath; Steel bars, hoop bars.

[0016] Step 3. Steel bar installation: Arrange radial steel bars on the farthest end plate edge from the center of the shaped plate. The steel bar spacing is the design spacing. This design spacing becomes smaller and smaller in the direction close to the center of the circle. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com