Self-restoration energy-consuming cable support system for multi-high-layer steel frame structure

A technology of energy-dissipating bracing and cable bracing, which is applied to building components, building types, and earthquake resistance, and can solve problems such as instability damage, difficult repairs, and complex anti-buckling bracing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

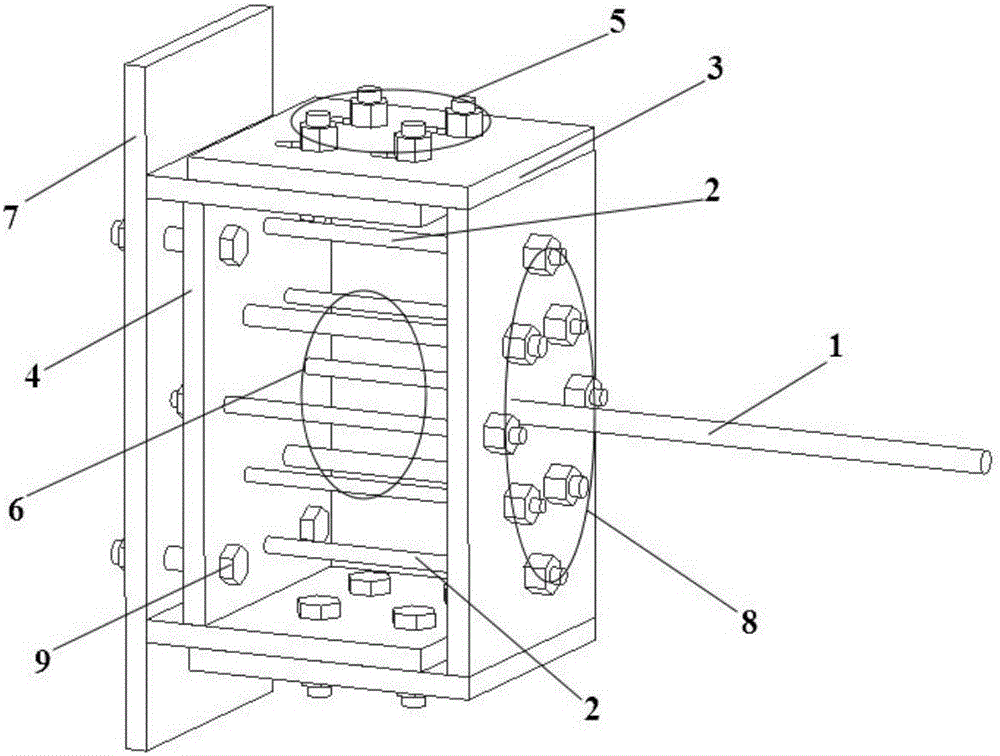

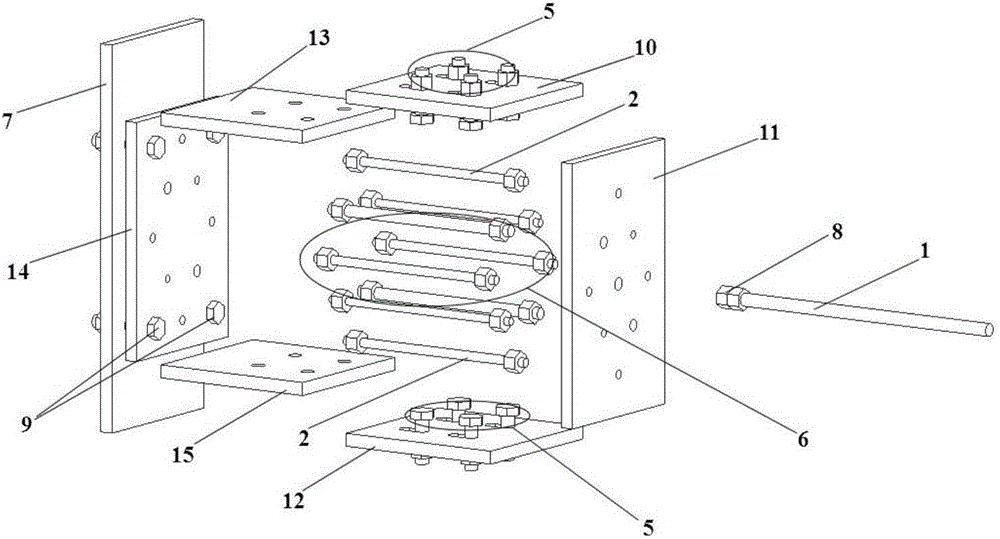

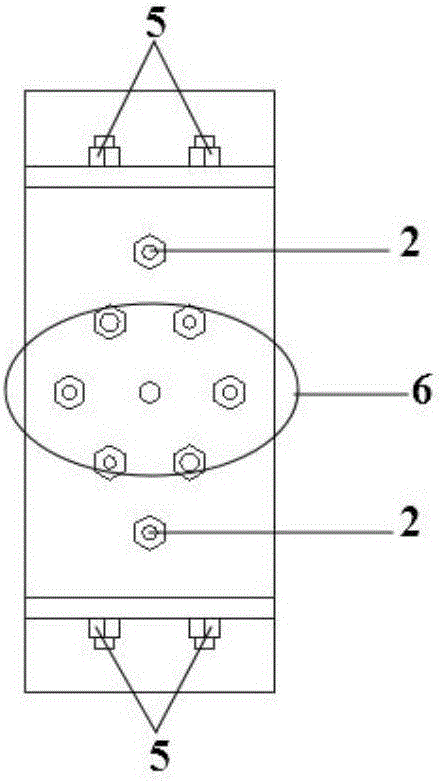

[0024] The present invention will be described in detail below in conjunction with the drawings:

[0025] As attached figure 1 And figure 2 As shown, the self-resetting energy-consuming cable support system of the present invention is assembled from various components, which greatly reduces welding work. First, after each plate is determined, open bolt holes and sliding holes according to the design requirements. The width of the hole is slightly larger than the diameter of the screw, but it should not be too large to avoid excessive reduction of the bolt preload. The length of the sliding hole should be based on The amount of structure side shift is determined. Weld the upper outer plate and lower outer plate of the large U-shaped notch on the upper and lower ends of the top plate respectively. The top plate is flush with the right ends of the two side plates, and the upper inner plate and the lower inner plate of the small U-shaped groove They are respectively welded on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com