Self-suction electric control low pressure fuel counter for internal combustion engine

A low-pressure fuel and measuring device technology, which is applied in the direction of machines/engines, liquid fuel feeders, and charging systems, can solve the problems of complex structure, poor hydraulic stability, and weak reliability of high-pressure generating devices, and achieve improved process Performance and reliability, good hydraulic stability, simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the invention.

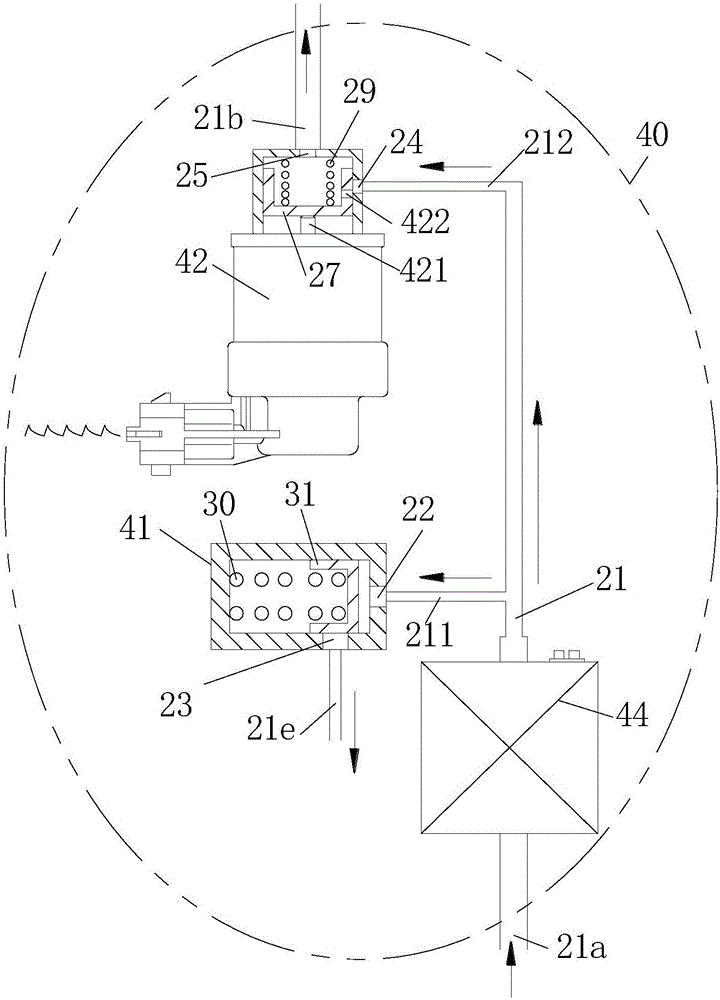

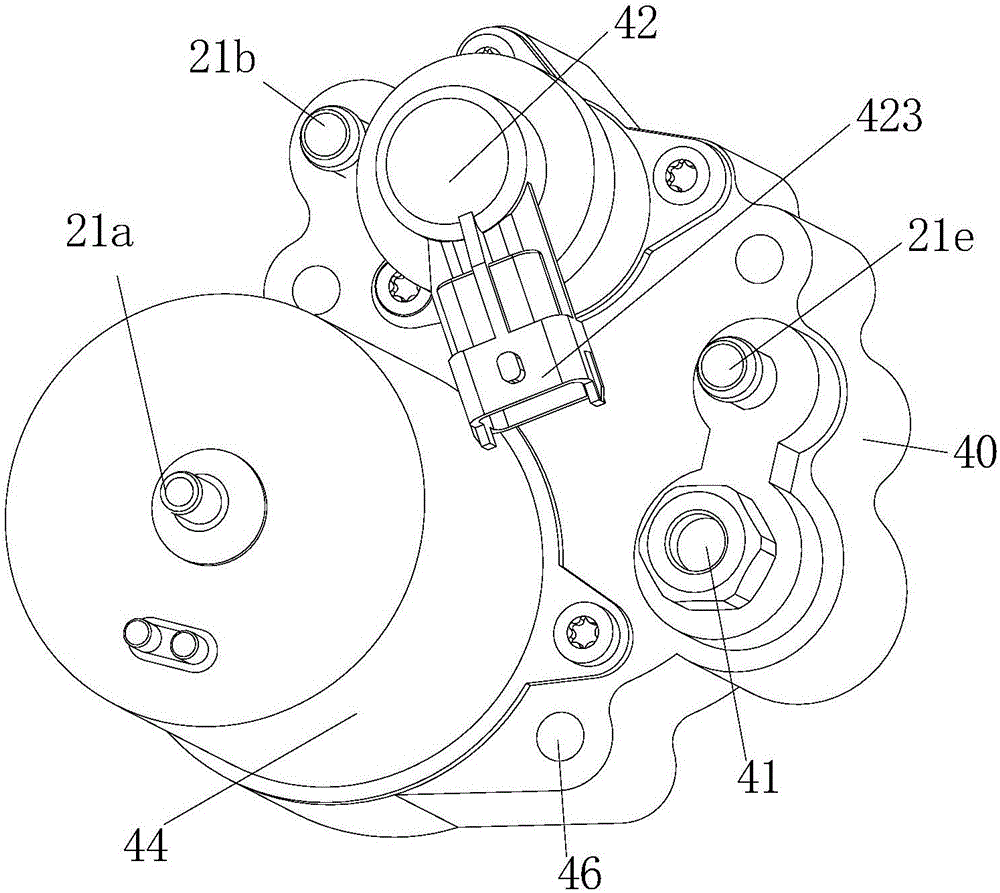

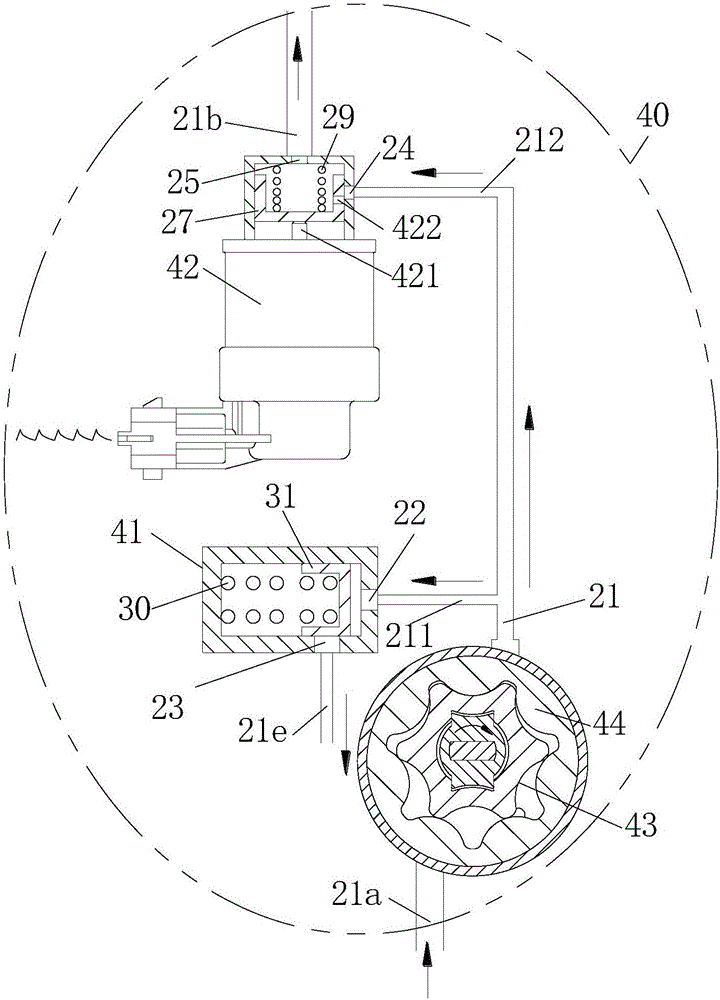

[0024] figure 1 A self-priming electronically controlled low-pressure fuel meter for a single-cylinder diesel engine according to the first embodiment is exemplified. The electronically controlled low pressure fuel gauge includes a gauge housing 40 . The electric low-pressure fuel delivery pump 44 integrated on the meter housing 40 pumps the diesel oil from the fuel tank (not shown) of the internal combustion engine (sometimes referred to as "engine") into the meter housing after boosting the pressure from the fuel inlet channel 21a The fuel main channel 21 in the body 40.

[0025] A pressure limiting valve 41 and an electronically controlled metering valve 42 are arranged in parallel on the fuel main passage 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com