Telescopic universal joint, drive shaft assembly and automobile

A universal joint and telescopic technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of increased axial force derived from ball rings and sliding sleeves, vibration and noise of telescopic universal joints, and restrictions on universal joints. Problems such as the maximum swing angle of the knuckle, etc., can eliminate the problem of failure abnormal noise, improve product reliability and durability, and simplify the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] Wherein, in the present invention, unless otherwise stated, the orientation words "inner and outer" used refer to the inner and outer relative to the outline of each component itself, but the above orientation words are not used to limit the present invention.

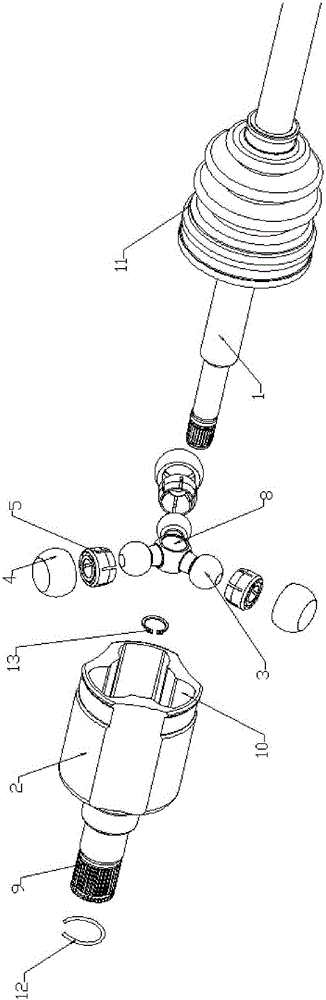

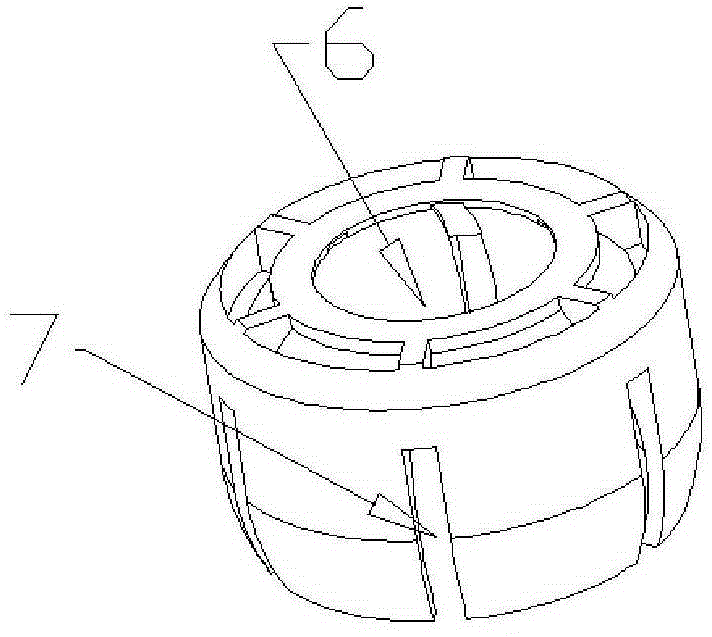

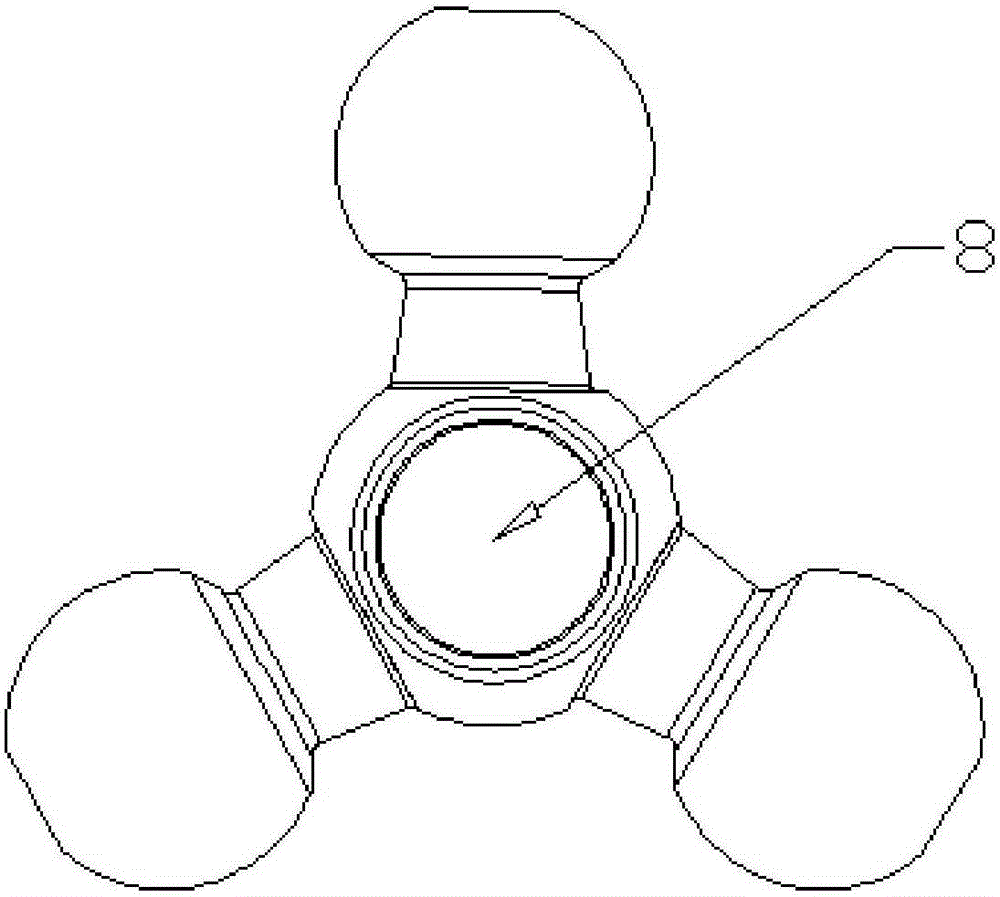

[0031] The present invention provides a telescopic universal joint, which includes a drive shaft 1, a tripod assembly connected to one end of the drive shaft 1, a driven shaft 9 and a drive shaft connected to the driven shaft. The sliding sleeve 2 at one end of 9, the tripod frame assembly includes a tripod frame 3, the tripod frame 3 includes three pin shafts, and the tripod frame assembly also includes a The three ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com