High-speed and large-torque waveform membrane disc flexible coupling

A flexible and high-torque technology of diaphragm, applied in high-torque couplings, high-speed high-torque waveform diaphragm flexible couplings, and high-speed fields, which can solve the problem that the calculation of torsional vibration of the unit shaft cannot pass and transmit torque. It is not strong and increases the additional load of the unit, so as to achieve the effect of good dynamic balance retention, simple structure and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

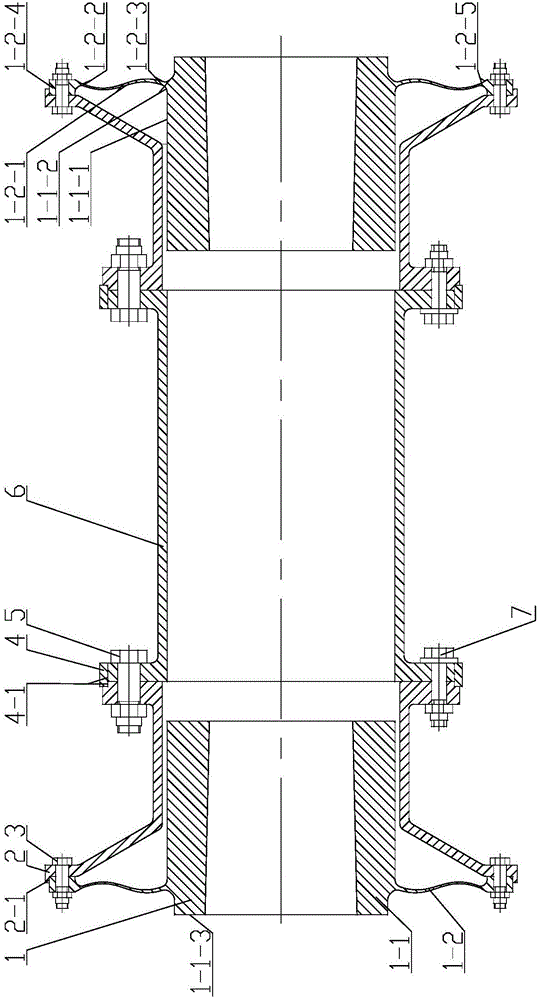

[0022] Such as figure 1 Shown: a high-speed, high-torque corrugated diaphragm disc flexible coupling, including a flexible mounting disc 1, an adapter disc 2, a positioning ring 4, and a spacer shaft 6; the spacer shaft 6 passes through the positioning ring 4 and the transfer disc 2 positioning, and connect and transmit torque through the second bolt assembly 5; the two groups of flexible mounting discs 1 and transfer discs 2 are symmetrically installed at both ends of the spacer shaft 6, and the flexible mounting disc 1 and transfer disc 2 pass through The first bolt assembly 3 is connected to transmit torque;

[0023] The flexible mounting plate 1 is an integrated structure, specifically including a mounting plate 1-1 and a membrane plate 1-2; The special curved surface features between circles 1-2-3 form a wave-curved surface 1-2-1. The axial thickness of the profile of the diaphragm 1-2 gradually increases from the profile outer ring 1-2-2 to the profile inner ring 1-2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com