High-performance gear for saving lubricating oil

A lubricating oil, high-performance technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve the problem of easy self-flow of lubricating oil, improve service life, reduce vibration, save energy The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

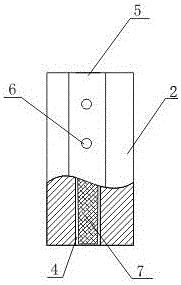

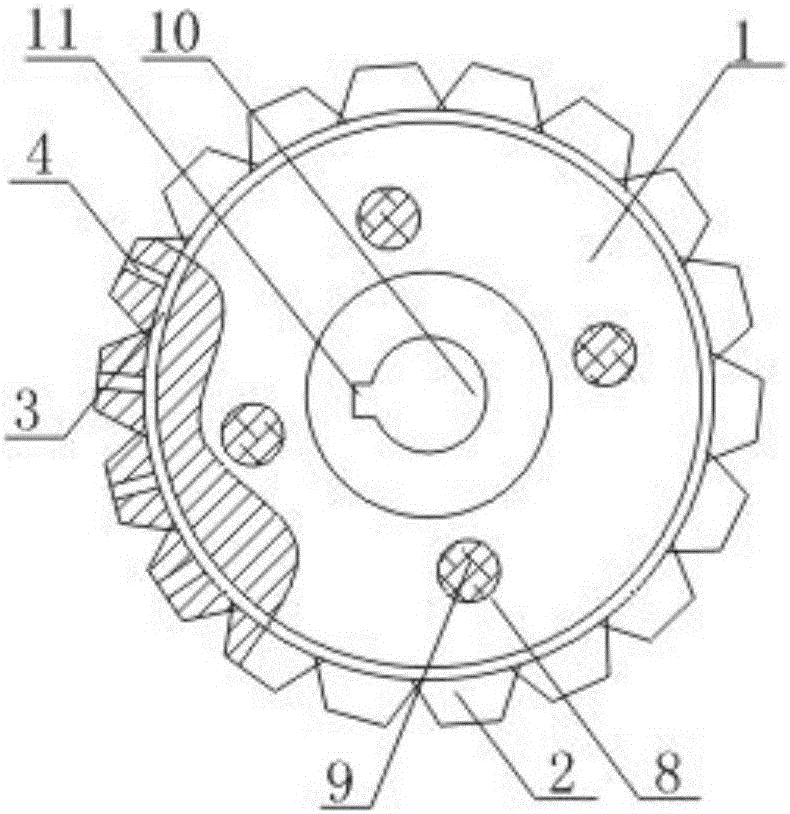

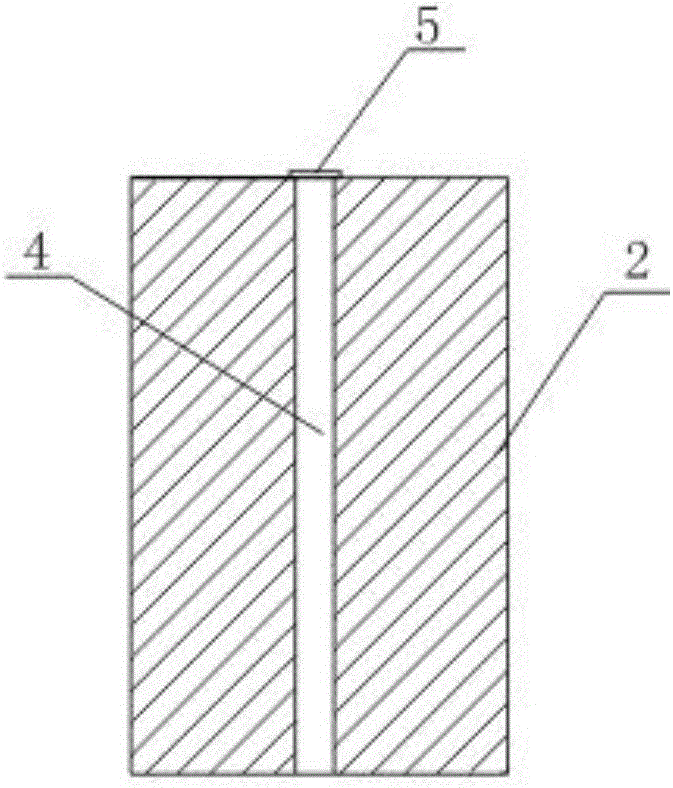

[0030] A high-performance gear that saves lubricating oil, including a gear body 1 and a plurality of gear teeth 2 evenly distributed on the gear body 1, and a lubricating oil receiving groove 3 is opened on the outer wall of the gear body 1 corresponding to the position where the gear teeth 2 are installed. The tooth 2 is longitudinally provided with an oil guide channel 4 communicating with the lubricating oil containing groove 3, and the outer end surface of the gear tooth 2 is provided with a retaining shell 5 covering the oil guide channel 4, and an oil outlet hole 6 is opened on the retaining shell 5 to guide A sponge 7 for absorbing lubricating oil is arranged in the oil channel 4 .

Embodiment 2

[0032] In this embodiment, on the basis of Embodiment 1, the blocking case 5 is an elastic blocking case.

Embodiment 3

[0034] In this embodiment, on the basis of embodiment 1 or embodiment 2, several lightening holes 8 are evenly opened on the gear body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com