Carbon steel ball valve

A ball valve, carbon steel technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problems of hidden leakage, high processing and assembly requirements, matching tolerances, etc., to achieve energy-saving processing efficiency, good anti-leakage, not easy shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

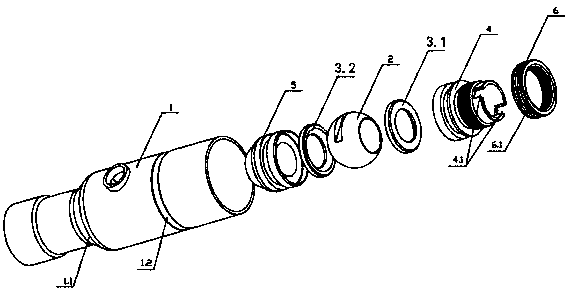

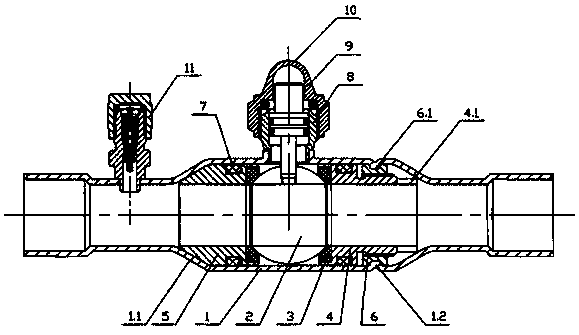

[0027] Such as figure 1 , figure 2 As shown, the ball valve of the present invention includes a ball valve main body 1, a ball 2, a first seal 3.1, a first inner plug body 4, and a second inner plug body 5; the ball 2 passes through the first seal 3.1 and the second inner plug body on both sides. The seal 3.2 is positioned in the inner cavity of the ball valve main body 1, and one end of the first inner plug body 4 and the second inner plug body 5 are both against the corresponding first seal 3.1 and the second seal 3.2, and the first inner plug body 4 Seal between the second inner plug body 5 and the ball valve body 1, that is, a sealing ring 7 is provided between the first inner plug body 4 and the second inner plug body 5 and the ball valve body 1; the pressure relief assembly 11 and the top connecting body 8 are all welded on the main body 1 of the ball valve, the valve stem assembly 9 is set in the top connecting body 8, and the cap 10 is screwed on the top connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com