Non-contact high-speed rail road foundation vibration measurement system

A high-speed railway foundation and vibration measurement technology, applied in the field of measurement, can solve the problems of low accuracy, large error, shortened service life of the measurement device, etc., and achieve the effect of high measurement accuracy and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

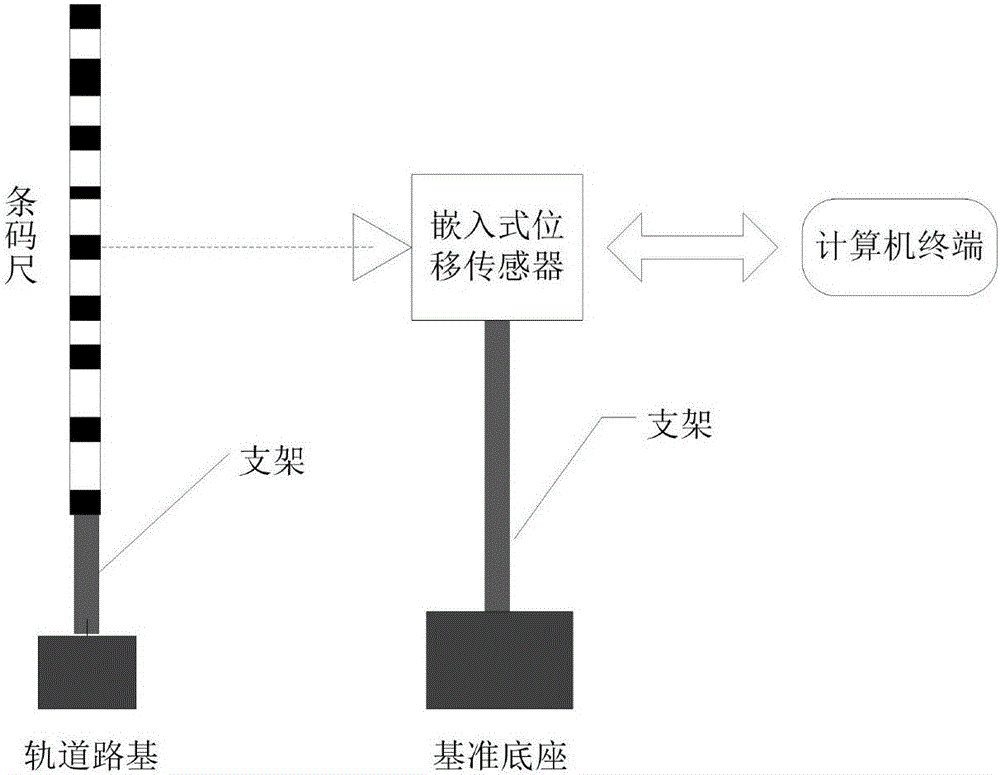

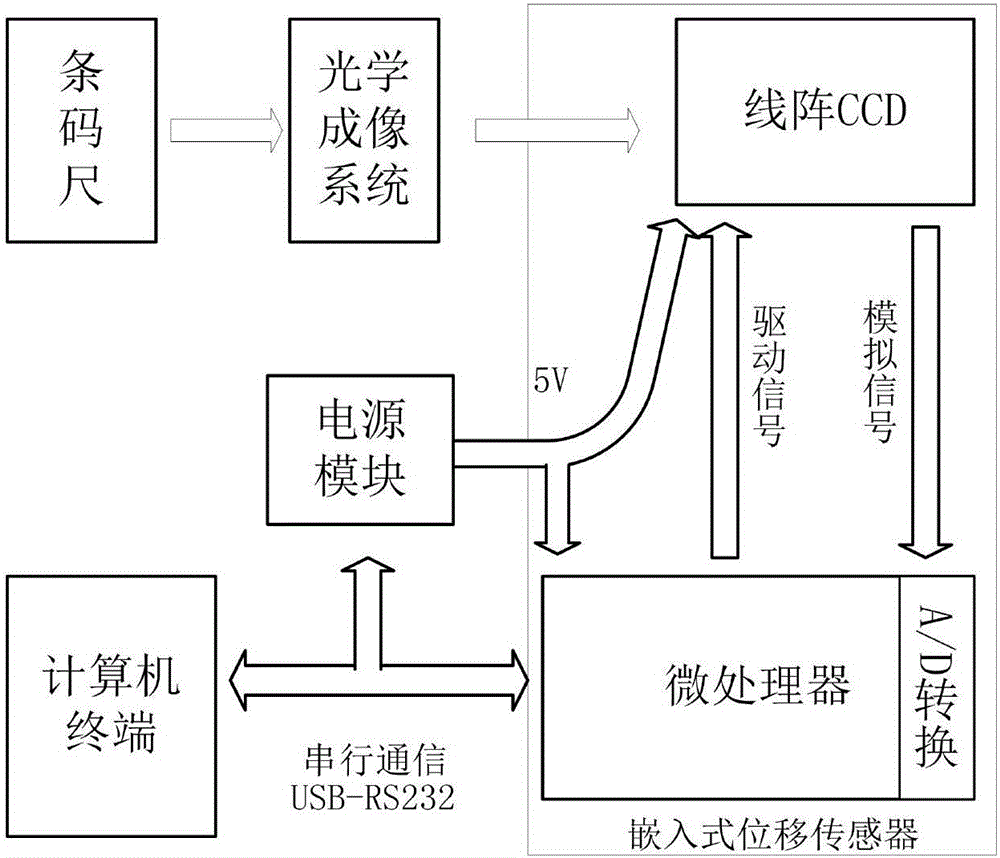

[0022] combine figure 1 , a non-contact high-speed railway foundation vibration measurement system, including a barcode ruler, an optical imaging system, an embedded displacement sensor, a computer terminal display module and a communication module. Among them, alternate black and white barcodes are set on the barcode ruler, and the width of the black barcodes is different, and the distance between the centers of two adjacent black barcodes is equal; the optical imaging system acquires real-time images of the barcode ruler according to a preset period; the embedded displacement sensor includes barcode Image acquisition and transmission module, information receiving and processing module, in which the barcode image acquisition and transmission module is connected with the optical imaging system to collect black barcode information, and the information receiving and processing module performs A / D conversion on the collected information and processes to obtain black barcode The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com