Force measurement composite device based on serial connection principle

A composite device and force technology, applied in the field of engineering, can solve the problem that the range and accuracy of the force sensor cannot be taken into account at the same time, and achieve the effects of accurate and reliable test results, strong practicability and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

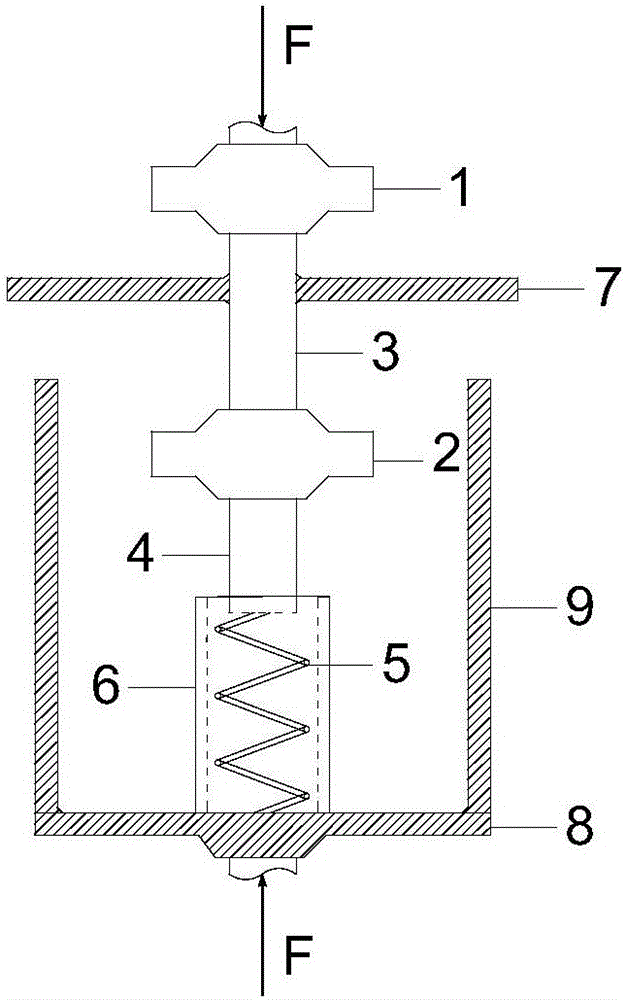

[0031] A force measuring composite device based on the series principle, such as figure 1 As shown, the device includes a connecting rod 3, a dowel bar 4, a large-range force sensor 1, a small-range force sensor 2, an upper supporting plate 7, a lower supporting plate 8, a spring 5, a spring sleeve 6 and a force transmitting frame 9, The large-range force sensor 1 and the small-range force sensor 2 are respectively arranged on the upper end and the lower end of the connecting rod 3, and the upper supporting plate 7 is arranged on the connecting rod 3, between the large-range force sensor 1 and the small-range force sensor 2, and the large-range The force sensor 1, the small-range force sensor 2, and the upper supporting plate 7 are arranged in series; the lower end of the small-range force sensor 2 is connected to the dowel 4, and the lower end of the dowel 4 is connected to the spring 5, and the length of the dowel 4 and the spring 5 is arranged in the spring casing 6, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com