Auto-coupling acoustic wave test system and acoustic wave test method

A test system and automatic coupling technology, applied in the direction of material analysis, measurement device, instrument, etc. using sonic/ultrasonic/infrasonic waves, which can solve the problems of energy loss at the transmitting end, increase the water injection volume, and inconvenience to move the sonic probe, and achieve good results. The effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

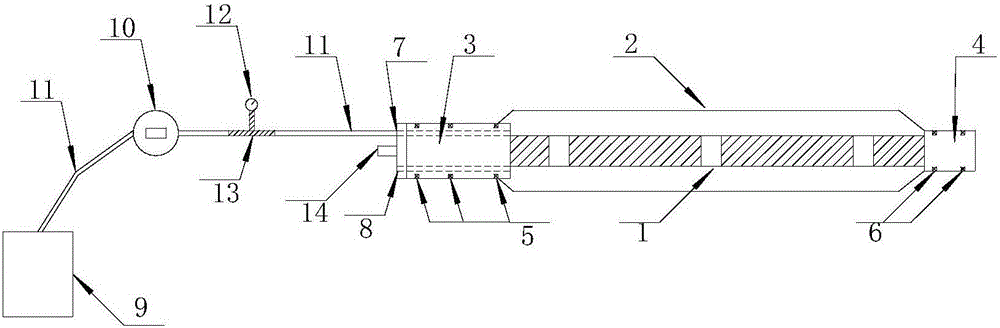

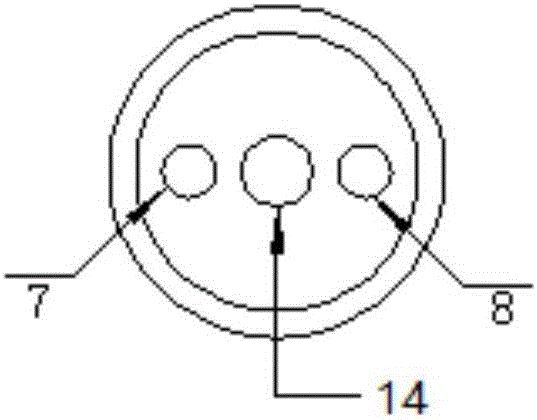

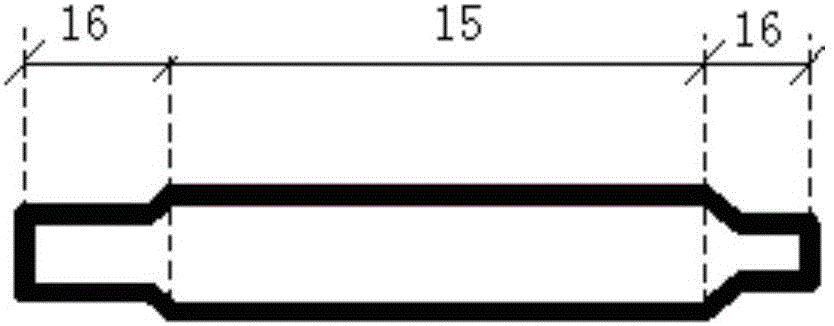

[0027] The automatic coupling acoustic wave testing system of the present invention is mainly composed of two parts: acoustic wave testing equipment and water injection pressurizing equipment. Such as figure 1 As shown, the acoustic wave testing equipment includes an acoustic wave probe 1 and a flexible impermeable water bag 2. One end of the acoustic wave probe 1 is provided with a water inlet joint 3, the water inlet joint 3 is a cylindrical stainless steel body, and the end of the water inlet joint 3 is provided with a water inlet Hole 7, sound wave signal cable passage hole 8 and push rod connecting bolt 14, the sound wave cable is sealed at the sound wave signal cable passage hole 8, and the sealing material can withstand the pressure of 0.3MPa. The outer surface of the water inlet joint 3 is provided with three ring-shaped water stop grooves 5, and the other end of the acoustic wave probe 1 is provided with a cylindrical stainless steel fixed short rod 4, and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com