Steady-state discrimination method for operation conditions in continuous production process

A discrimination method and production process technology, applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve the problems of measurement data fluctuation, detection result influence, industrial data difficult to run steady-state detection and other problems, so as to reduce errors effect, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

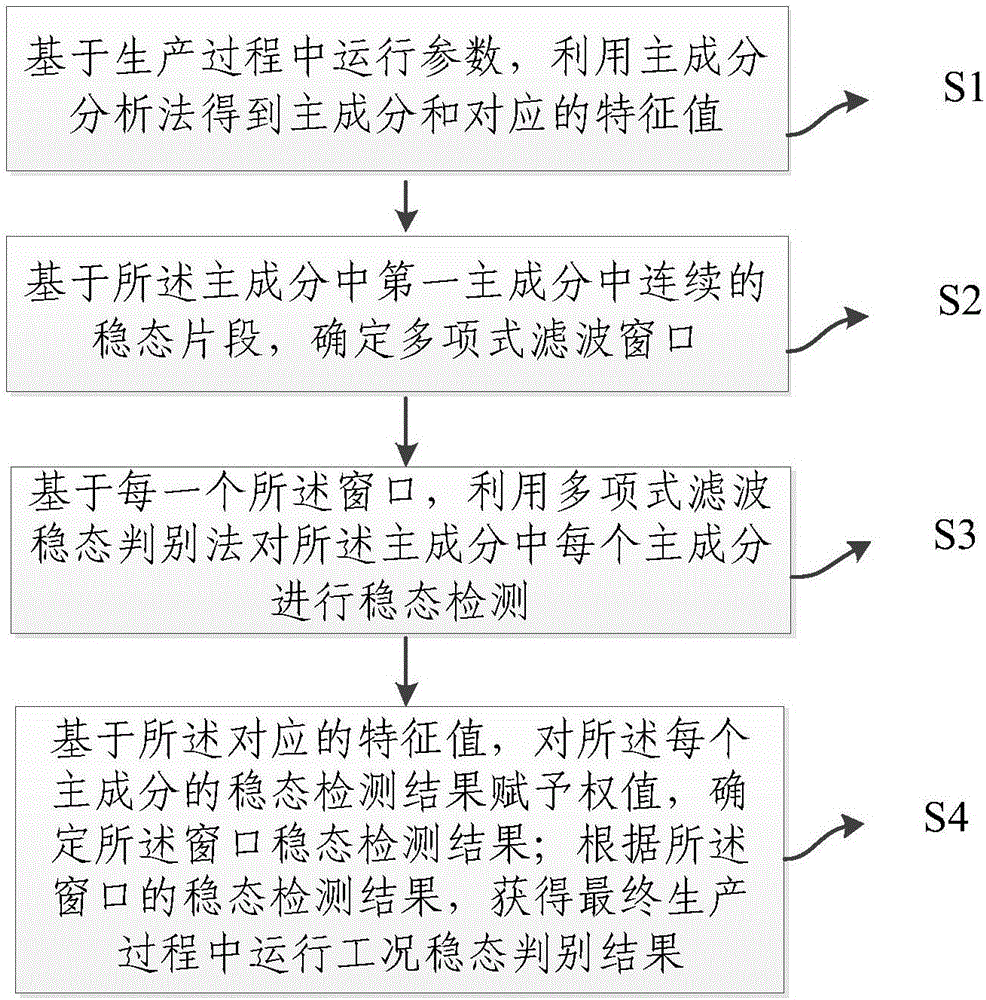

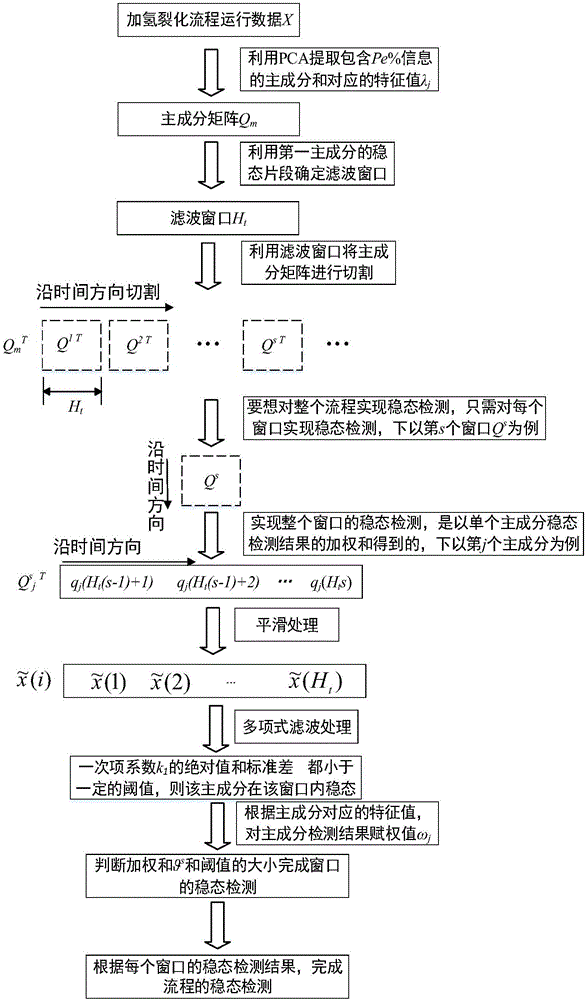

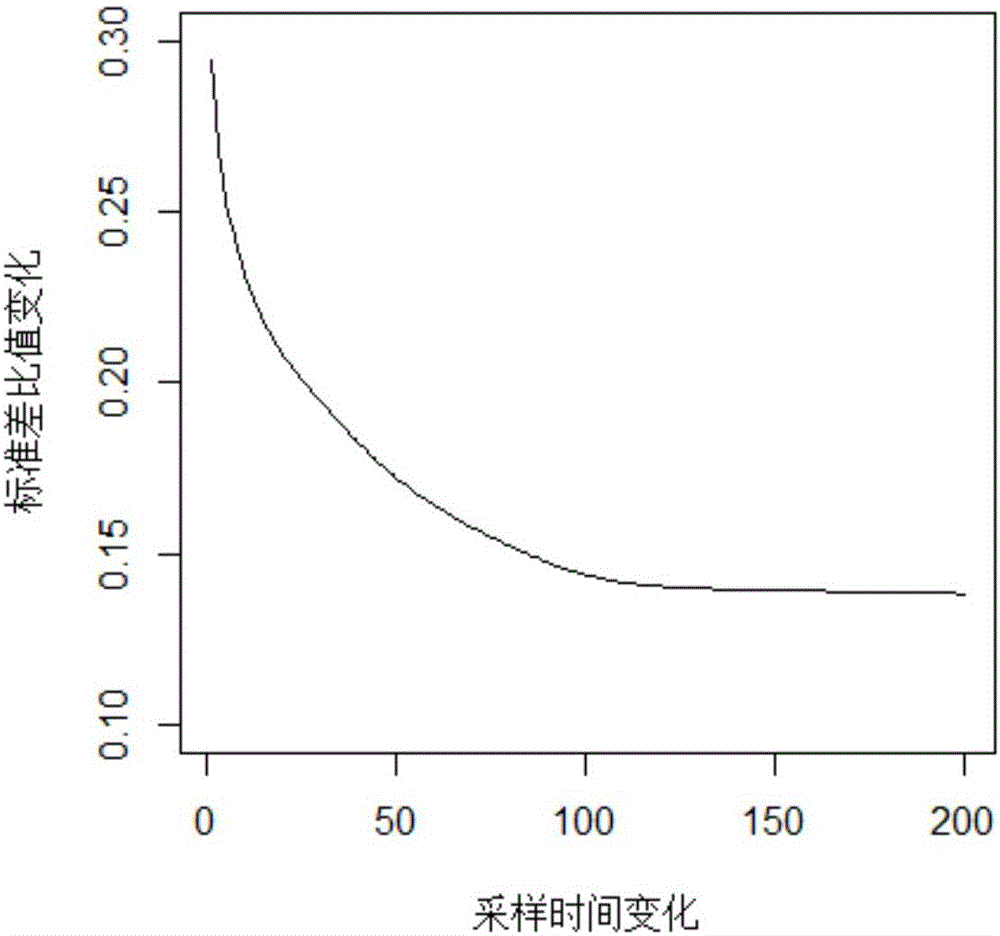

[0074] The steady-state discrimination method of the operating conditions in the continuous production process provided by this embodiment takes the hydrocracking process as the object, and aims at the problem of many monitoring parameters and high coupling of the hydrocracking process, uses PCA to extract the main components, and realizes the reduction. The role of maintenance and decoupling is to use polynomial filtering to achieve steady-state detection of the smoothed principal components, and to assign a certain weight to the steady-state detection results of a single principal component through the eigenvalues of the principal components. Finally, judge the hydrocracking process based on the weighted sum Is it in a steady state. The specific process is as follows:

[0075] The hydrocracking monitoring variables selected in this example include total outlet feed oil flow adjustment, hydrofinishing reactor 1 bed temperature (top), hydrofining reactor 2 bed temperature (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com