Automobile molding greasy filth frame wheel installation apparatus

An installation device and sludge technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as the inability to perform dynamic evaluation, the inability to obtain evaluation data, and the inability to realize wheel adjustment for oily sludge vehicles, so as to facilitate design and adjustment operations, and facilitate the Design and implementation, the effect of easy design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

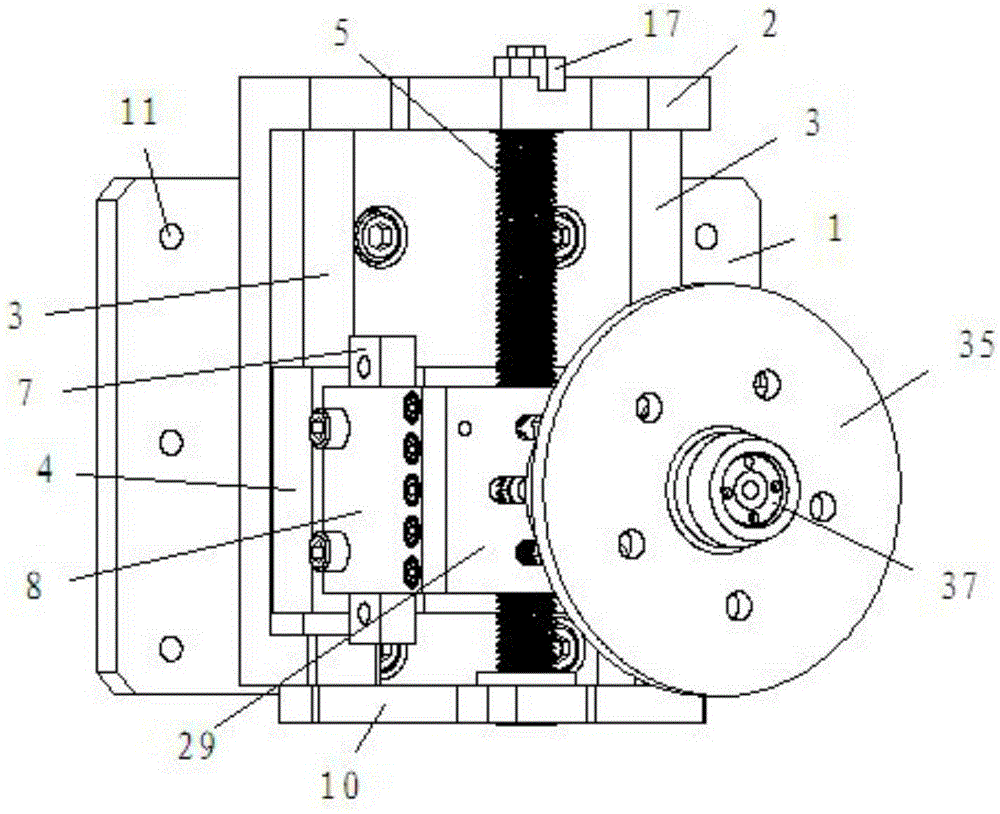

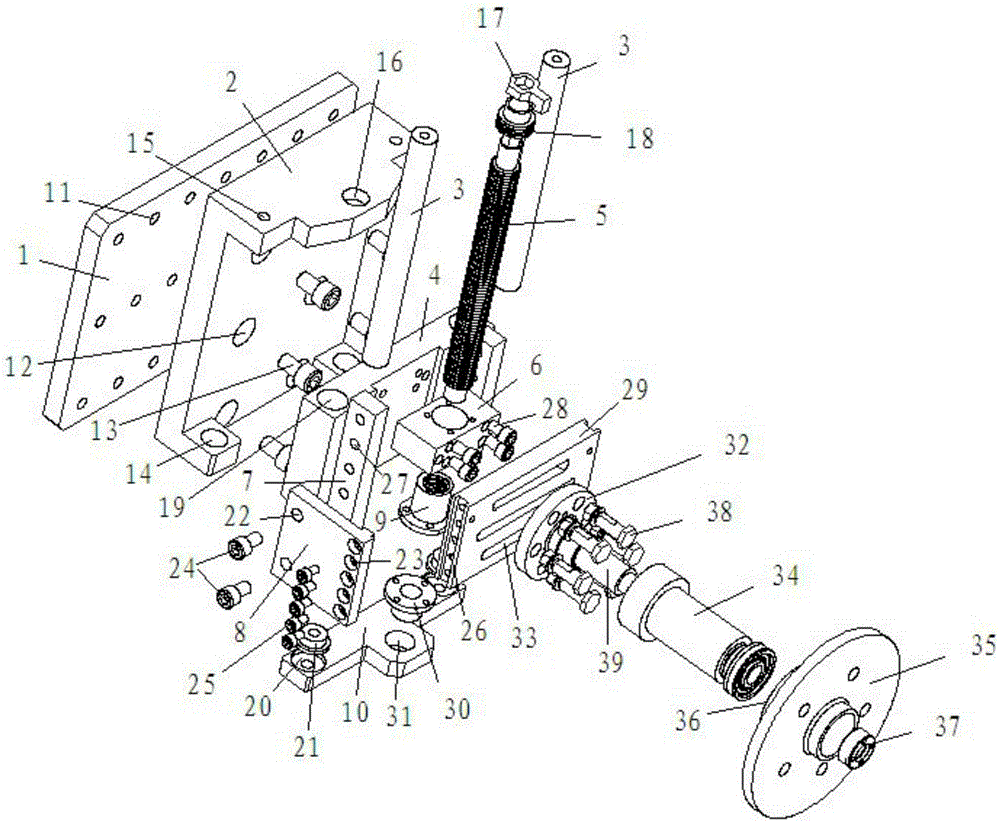

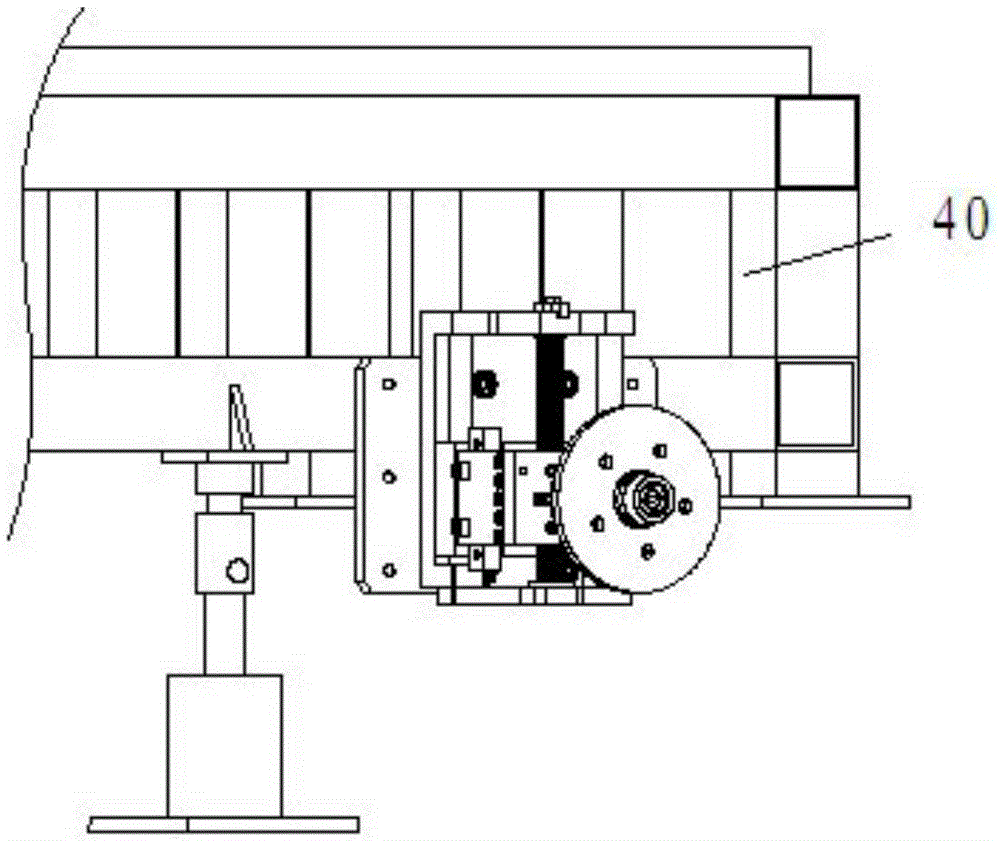

[0032] This embodiment relates to a wheel mounting device for a car-shaped sludge frame, which is used for the installation of wheels on a sludge frame. A three-way adjustment mechanism is also connected between the frames to make the wheel installation part adjust the position along the length direction, width direction and height direction of the sludge frame. Among them, the three-way adjustment mechanism includes a horizontal adjustment part connected with the sludge frame, which can adjust the wheel mounting part along the length direction of the sludge frame, and is connected to the lateral adjustment part, which can adjust the wheel mounting part along the height direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com