Battery equipped with large-pore-diameter insulating ring

An insulating ring and large-aperture technology, which is applied in the direction of battery boxes/coats, battery pack components, circuits, etc., can solve problems such as prone to missing inspections, potential safety hazards, and easy to drop, so as to prevent misalignment and drop, reduce Possibility, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

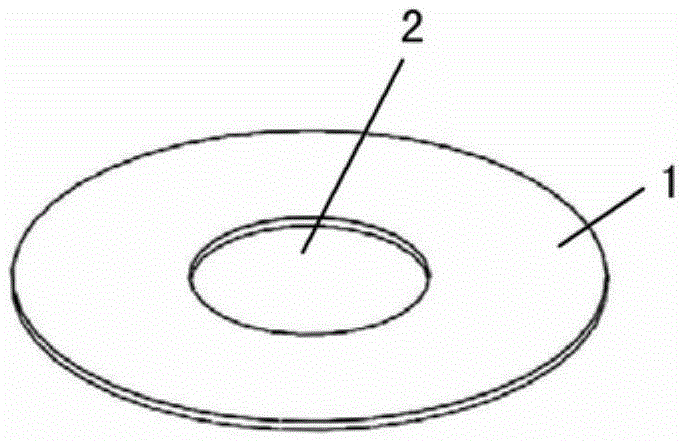

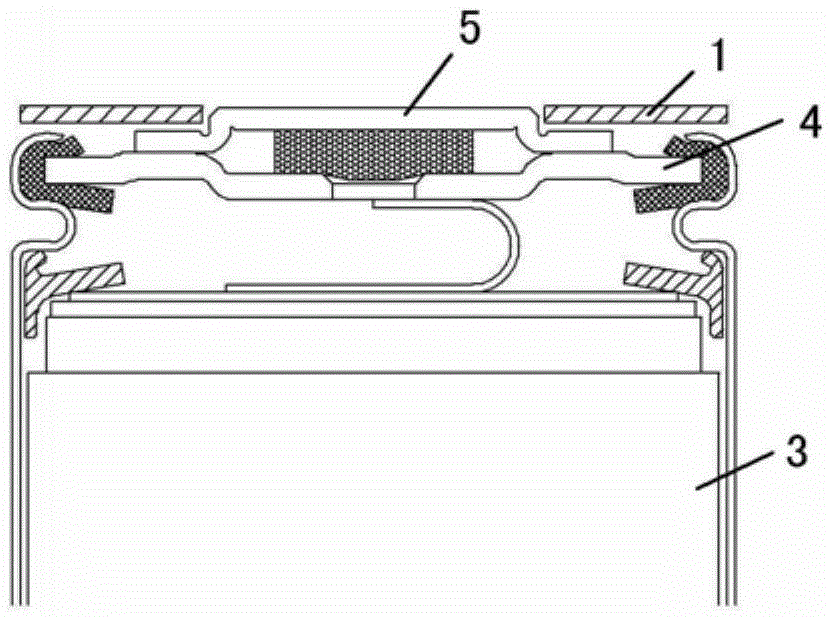

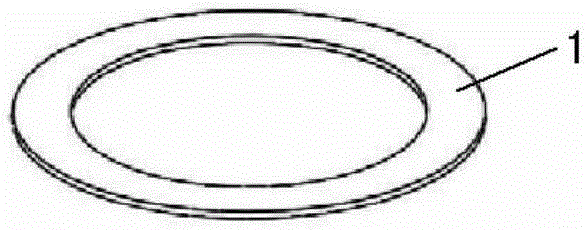

[0044] Hereinafter, the large-aperture insulating ring of the present invention and the battery having the large-aperture insulating ring of the present invention will be described in detail with reference to the accompanying drawings. However, the insulating ring and the battery of the present invention are not limited to the following specific specific forms.

[0045] A secondary battery (hereinafter simply referred to as a battery) includes a bare cell, an insulating ring covering a sealing plate of the bare cell, and a heat shrinkable sleeve covering the bare cell and the insulating ring. The bare cell is composed of a metal battery case, a sealing plate, and a power generating element sealed in an airtight cavity formed by the battery case and the sealing plate. The upper end of the opening of the battery case is caulked to the sealing plate through the insulating gasket to form a closed bare cell. An insulating ring is placed on the sealing plate of the bare cell, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap