Sealing structure for redox flow battery

A technology of sealed structure and liquid flow battery, which is applied in the direction of fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of large bending and shear stress of bipolar plates, the inapplicability of nitrile rubber, and the impact on the performance of battery stacks, etc., to achieve Improved safety, low cost, and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

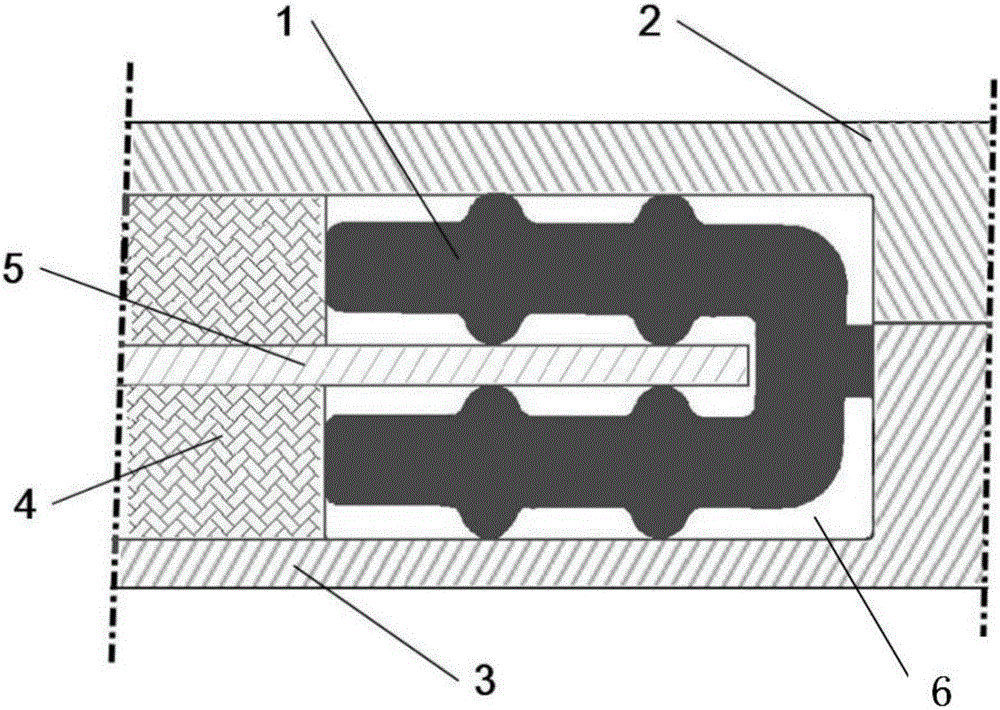

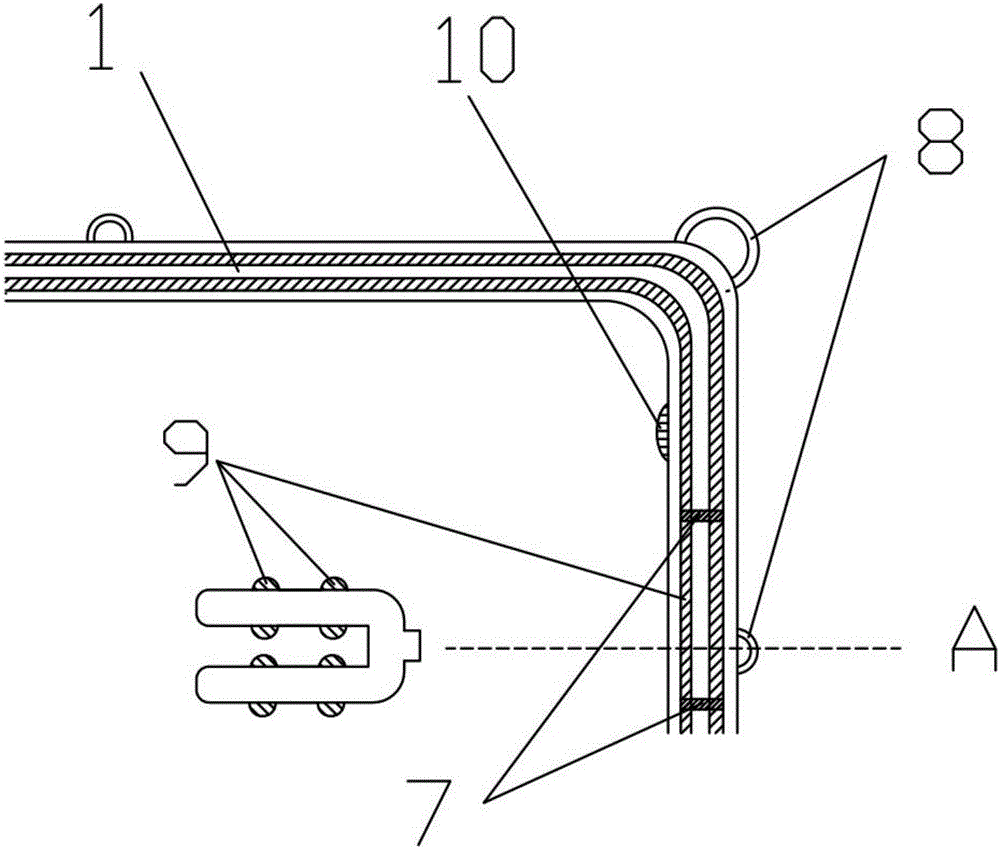

[0032] Example as Figure 1-3As shown, the material of sealing ring 1 in this embodiment is EPDM rubber, and its hardness is 60-75 degrees Shore; Greater than the depth of the groove 6 on the plate frame, the internal length and width of the sealing ring 1 are slightly smaller than that of the bipolar plate 5 . Such as figure 1 As shown in or 3, the cross section of the sealing ring 1 is a "匚"-shaped opening structure, the inner side of the opening is used to envelop the double-plate pole 5, and the upper and lower inner sides and two outer sides of the opening are provided with a total of 4 surfaces. 8 (4 rows and 2 rows) protruding long waterlines 9, the positions of two rows of long waterlines 9 are up and down. Between the two long waterlines 9 on the upper and lower outer surfaces of the sealing ring 1, several auxiliary waterlines 7 in the vertical direction are arranged to prevent the liquid inside the sealing ring 1 from leaking. The two inner sides of the "匚"-shap...

Embodiment 2

[0038] Example two such as Figure 4-5 As shown, the material of the sealing ring 1 in the second embodiment is fluorine rubber, and the hardness is 60-75 degrees Shore. The sealing ring 1 has a "□"-shaped structure, and the middle part of a short side of the sealing ring 1 is provided with a sealing structure tap 11 of a bipolar plate tap. The depth of the groove 6; the internal length and width of the sealing ring 1 is slightly smaller than the size of the bipolar plate 5; There are 8 (4 rows and 2 rows) protruding long waterlines 9 on the 4 surfaces of the upper and lower inner sides and the two outer sides, and the positions of the two rows of long waterlines 9 are up and down. Between the two long waterlines 9 on the upper and lower outer surfaces of the sealing ring 1, several auxiliary waterlines 7 in the vertical direction are arranged. The arrangement of the auxiliary waterlines 7 can prevent the liquid inside the sealing ring 1 from leaking. The long waterlines 9 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com