Heat dissipation mechanism of motor with built-in control system

A control system and heat dissipation mechanism technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing line loss and system cost, high failure rate, inconvenient installation, etc., to save labor costs, reduce failure rate, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

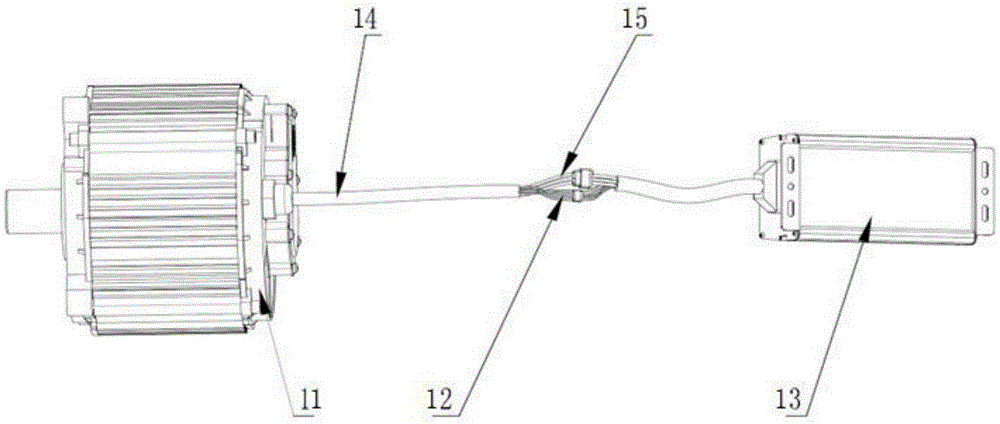

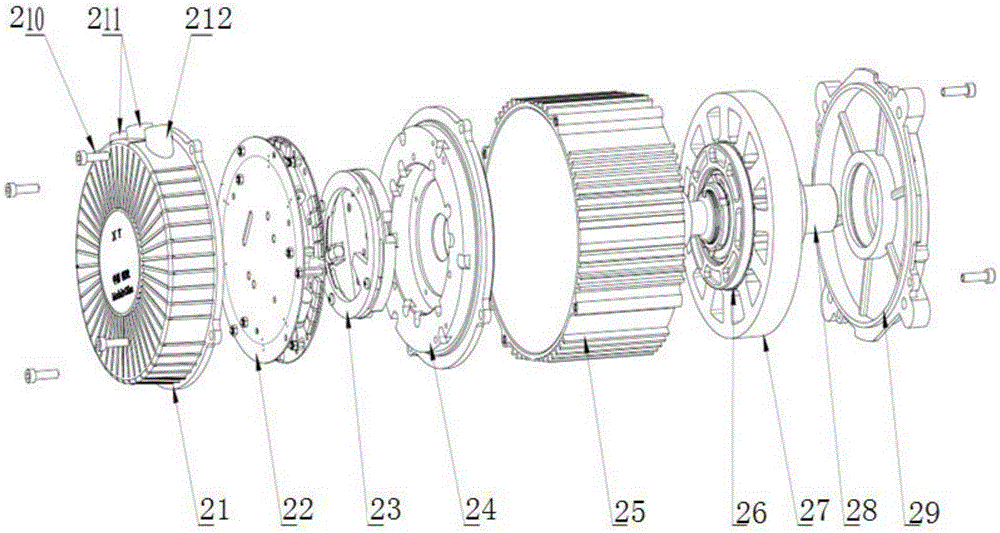

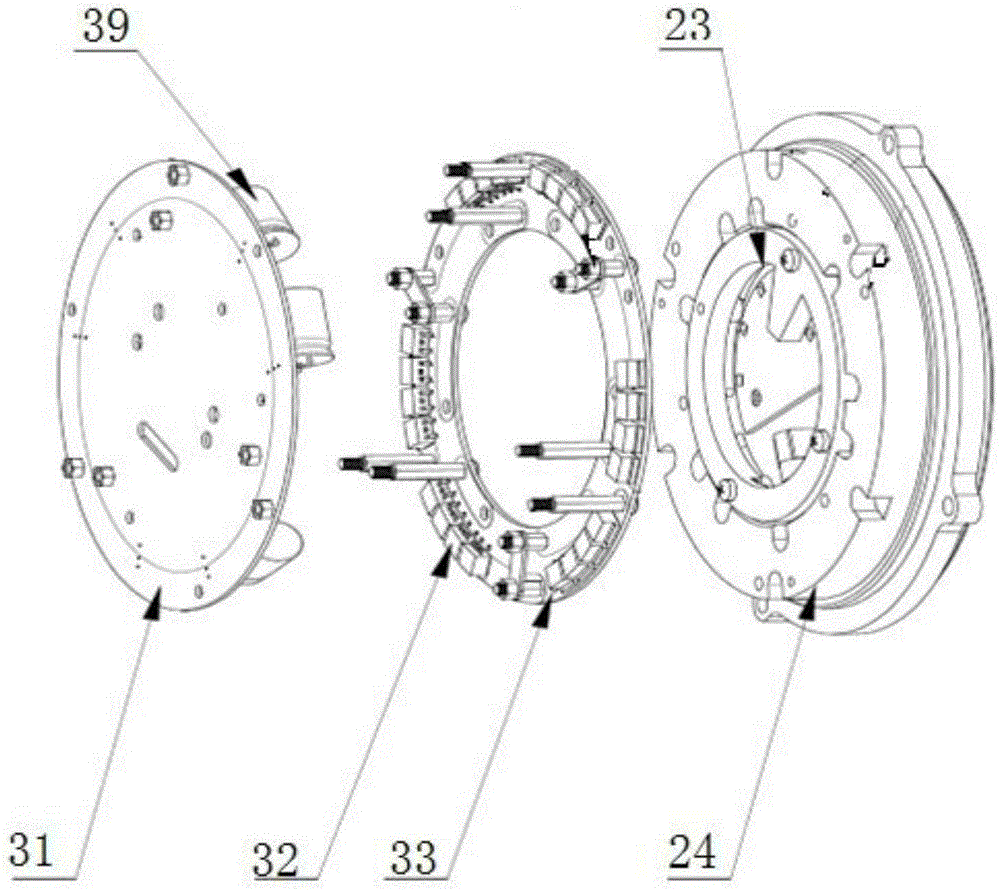

[0030] Such as figure 2 As shown, a motor heat dissipation mechanism with a built-in control system is characterized in that it includes a shield, a casing, a rotor, a stator and a main shaft; it also includes a motor control system;

[0031] From one side of the motor to the other side are the shield, the control system, the rear end cover, and the casing; the casing includes the rotor, stator, and main shaft; the outermost is the front end cover;

[0032] Air inlet holes are arranged on the shield, and air outlet holes are arranged on the side wall of the shield;

[0033] The shell is a hollow structure, grooves are uniformly arranged on the inner side of the shell wall, and a number of through holes are evenly set between the inner side and the outer side of the shell wall, and the through holes are connected to the air inlet of the shield and the front end cover; the front end Raised cooling points are uniformly arranged on the cover;

[0034] A bar-shaped air outlet is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com