Method and system for thermally treating dispersible raw materials

A raw, decentralized technology for climate sustainability, lighting and heating equipment, furnaces, etc., that solves problems such as high complexity of installation equipment, eliminates high complexity, avoids temperature peaks, and promotes temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

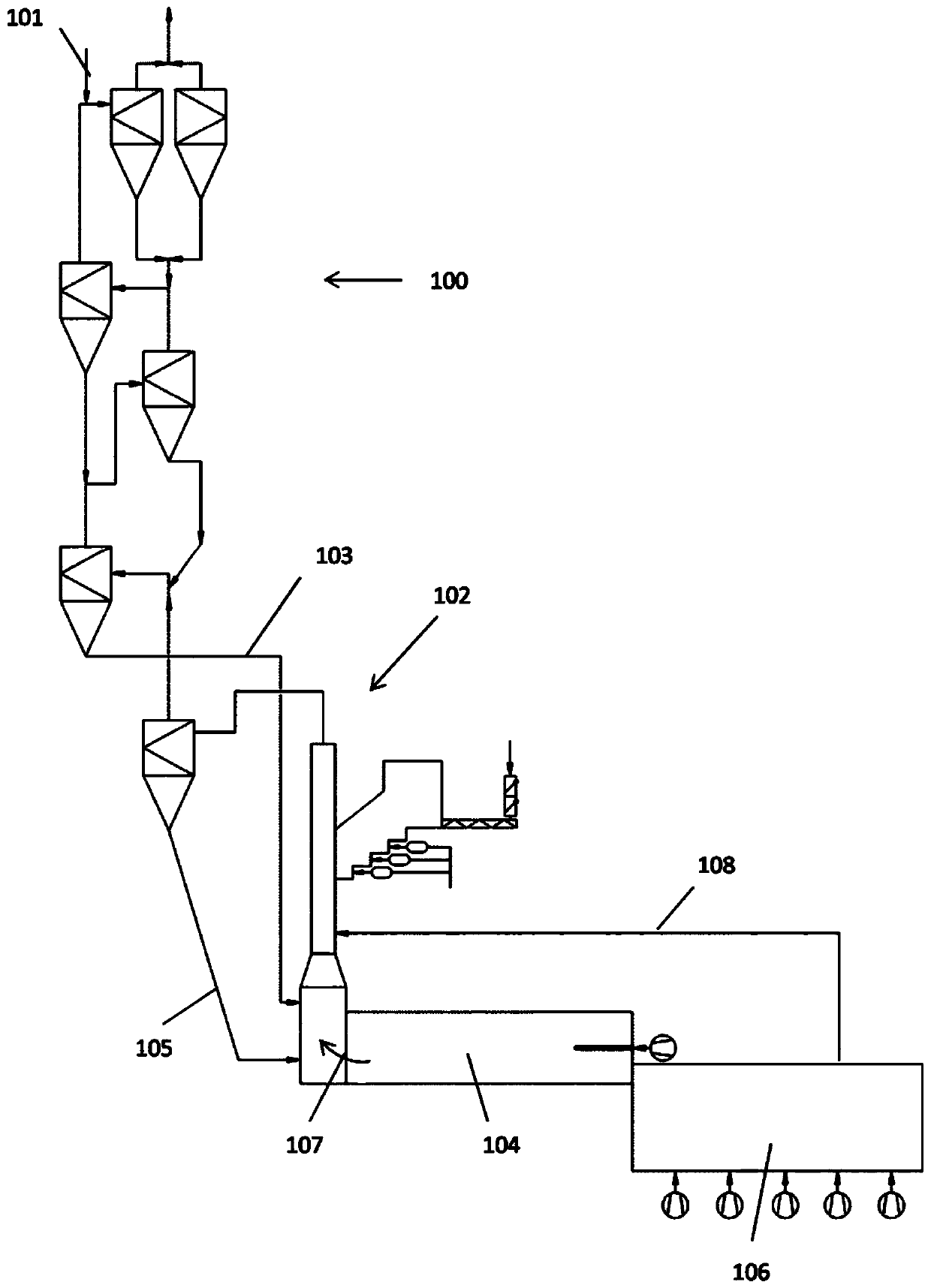

[0027] figure 1 Shown is a system for producing cement clinker with a multi-stage preheater 100 for preheating cement raw meal 101, a calciner 102 for precalcining preheated cement raw meal 103, a calciner 102 for calcining A furnace 104 for firing pre-calcined cement raw meal 105 to form cement clinker, and a cooler 106 for cooling the cement clinker. The hot gases 107 produced in the furnace 104 first flood the calciner 102 and then the preheater 100 . Furthermore, cooler off-gas 108 produced in cooler 106 is used as combustion air in calciner 102 .

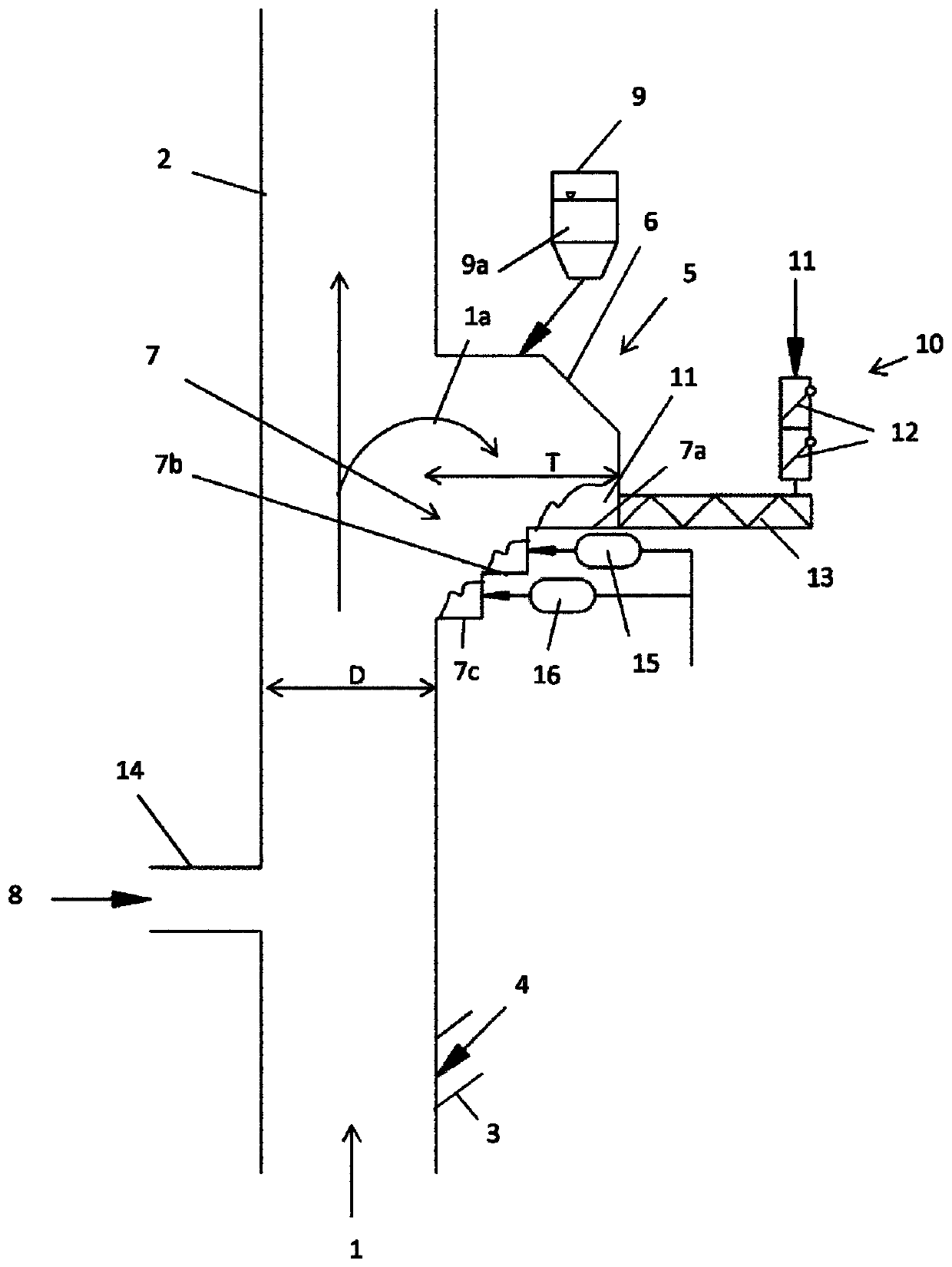

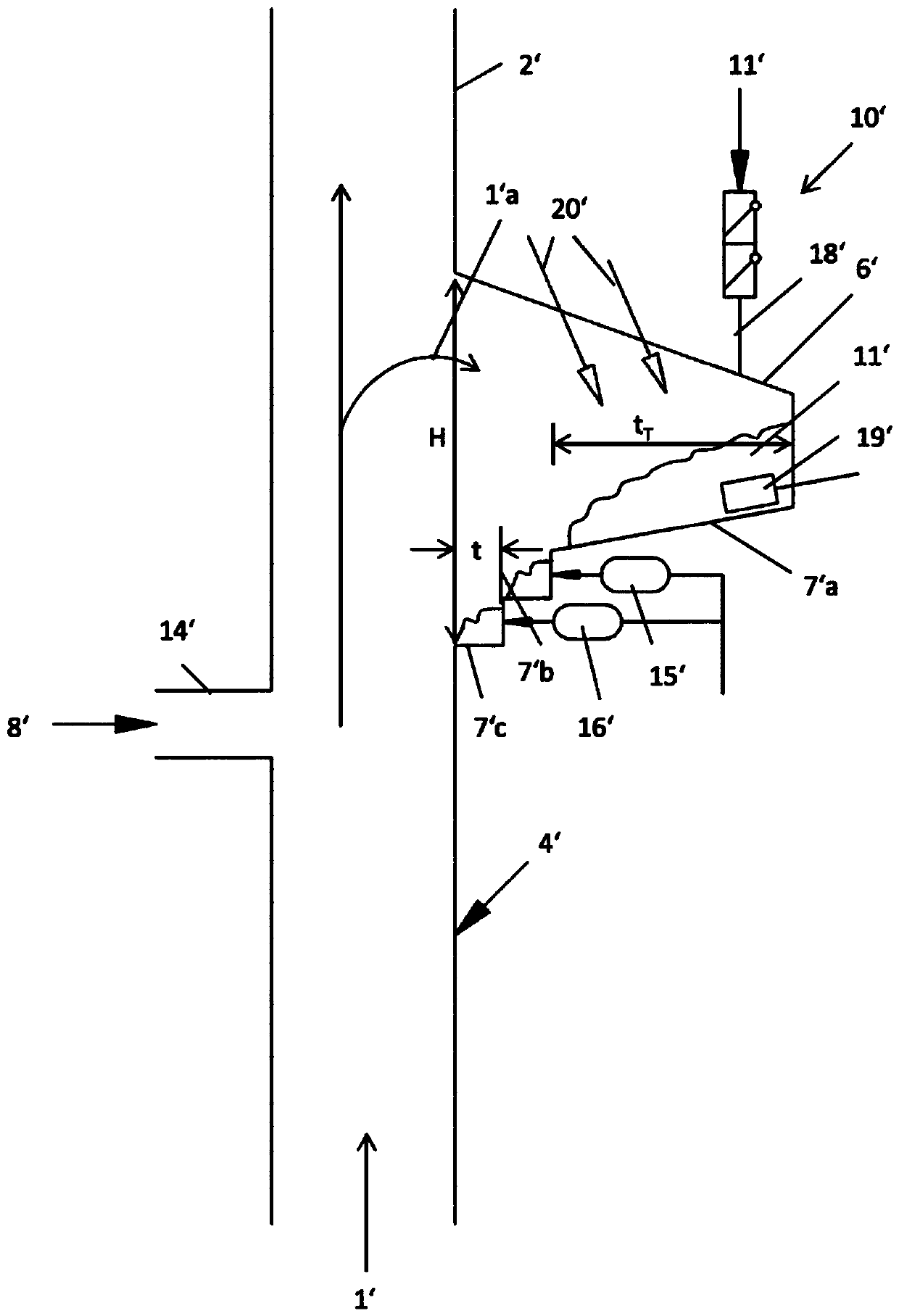

[0028] pass Figures 2 to 4 Various exemplary embodiments of the configuration of the calciner are shown. However, these exemplary embodiments may also relate to other systems for thermal treatment or chemical reactions of dispersible raw materials (eg ore reduction) and are therefore not limited to calciners.

[0029] figure 2 The system for thermally treating dispersible raw materials shown in has a standpipe 2 filled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com