Methods of detecting flow line deposits using gamma ray densitometry

A technology of flow pipelines, gamma rays, applied in the use of wave/particle radiation for material analysis, measuring devices, using wave/particle radiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

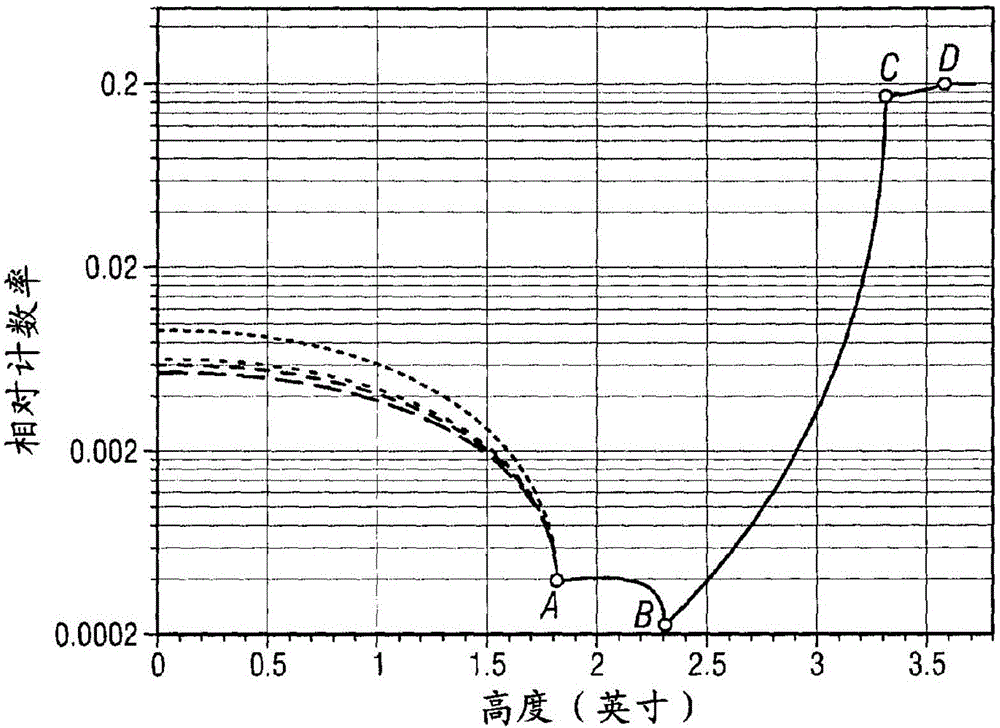

[0056] The first pipe had an inner diameter of 4.6 inches, an outer diameter of 6.6 inches, and was coated with a wax deposit of 0.3 inches. Fouling deposits were used to prepare a second pipe having an inner diameter of 4.6 inches, an outer diameter of 6.6 inches, and a coating of 0.3 inches. A mixture of oil and natural gas flows through the first pipeline and the second pipeline. Densitometers including sources and detectors were placed on either side of each tube and photon counts were measured at different heights along the axis of each tube. The relative counts of photons measured for each pipeline are plotted on the graph. Figure 6 Show the results of this graph. Analyzing the graph, it was determined that the deposit thickness on each pipe was 0.5 inches by locating points of intersection and minima.

example 2

[0058] In addition to the first and second pipes in Example 1, a third pipe was prepared having an inner diameter of 4.6 inches, an outer diameter of 6.6 inches, and a coating of 0.3 inches. The same mixture of oil and gas as the first and second conduits flows through the third conduit. Densitometers including sources and detectors were placed on either side of the third tube and photon counts were measured at different heights along the axis of each tube. The relative counts of photons measured for both the first and second conduits are divided by the relative counts of photons measured for the third conduit to obtain corrected decay counts, and will be corrected for each of the first and second conduits The decay counts for are plotted on the graph. Figure 7 Plot the results of this chart. Analysis of the graph, by locating local minima and junctions, determined that the deposit thickness on each pipe was 0.5 inches.

example 3

[0060] Use the following equation to calculate the thickness of the sediment measured for each chord of the first and second conduits:

[0061]

[0062] For both the first and second pipelines, one obtains μ Water , μ insulation , μ wall , μ stream and μ deposit value. Compute l at each chord using the following equation Water value, l insulation value and l wall value:

[0063] l=2[(R 1 )Sin(a cos(h / R 1 )-(R 2 )Sin(a cos(h / R 2 )]

[0064] Once each l is calculated for each chord length deposit value, to determine the largest l for the first and second pipelines deposit The value is 0.5 inches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com