Controller and method for minimizing scale factor errors of a rotation rate sensor

A technology of rotation rate and control device, which is applied in the direction of measuring device, gyroscope/steering sensing equipment, instrument, etc., and can solve the problems affecting the measurement accuracy of rotation rate sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the figures, parts or groups of parts corresponding to each other are marked with the same reference numerals.

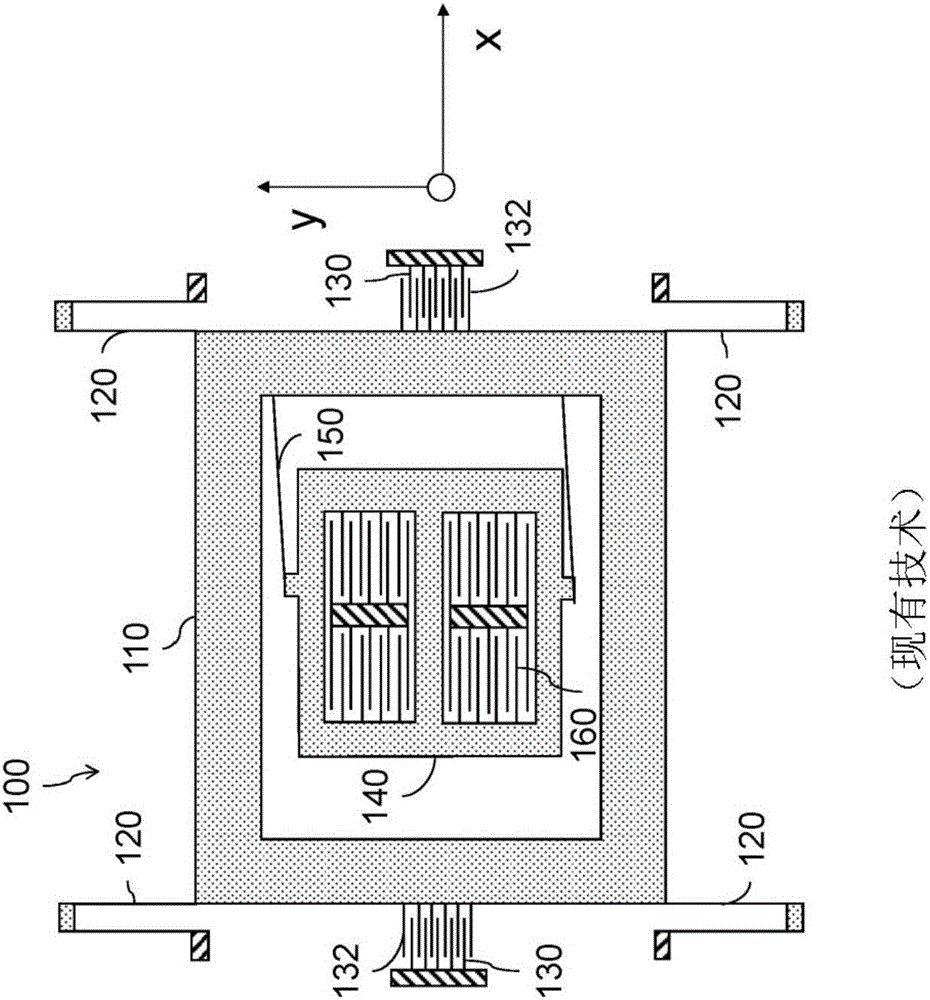

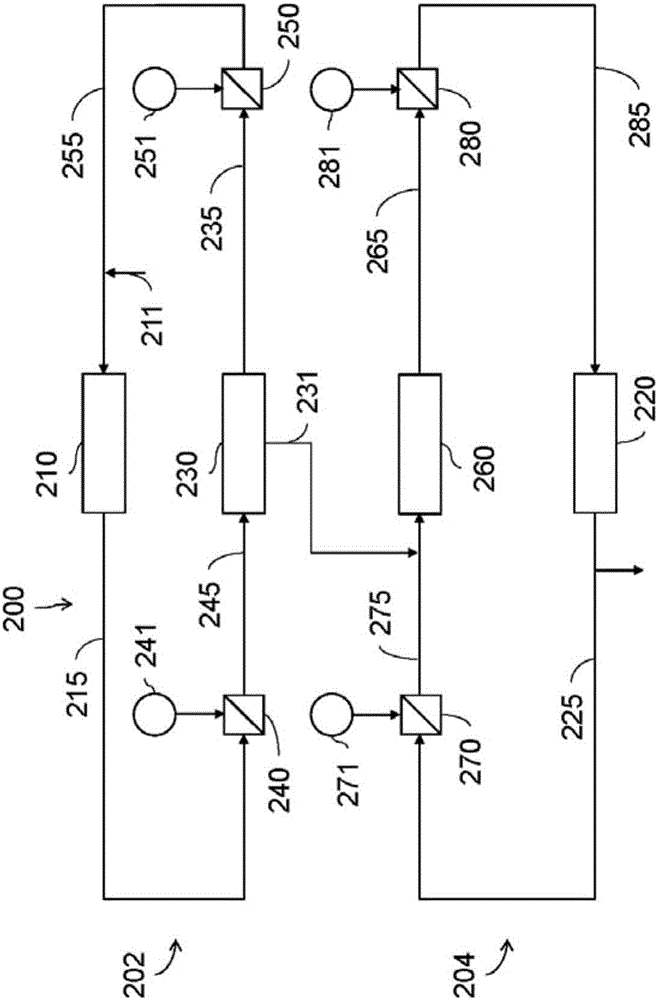

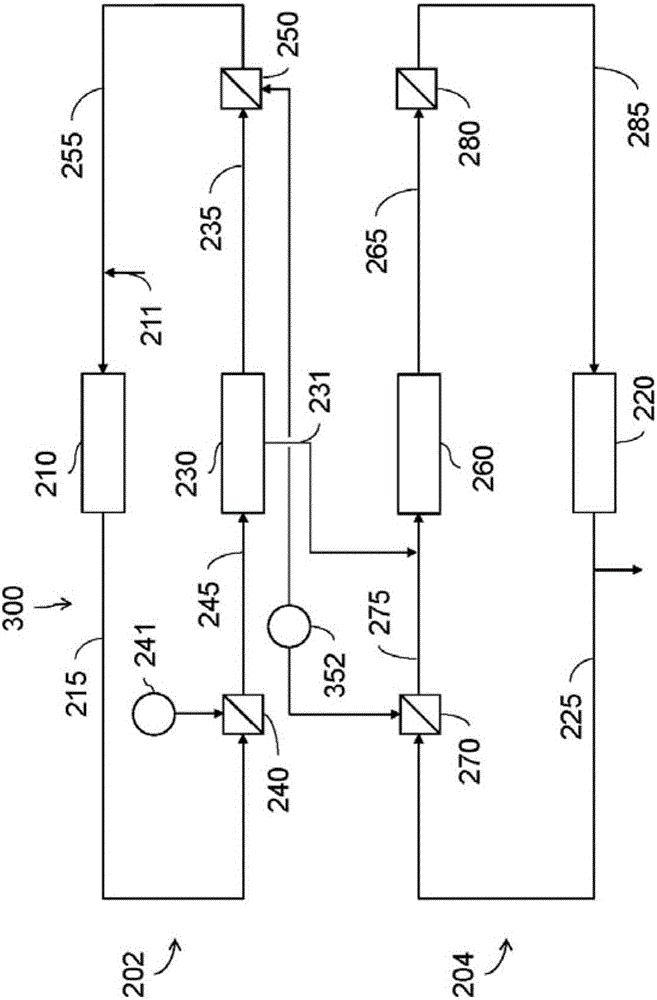

[0041] figure 2 A schematic block diagram of a control device 200 for controlling a rotation rate sensor is shown. The rotation rate sensor can refer to the reference figure 1 the sensor. The rotation rate sensor may be, for example, a microelectromechanical sensor (MEMS).

[0042] The control device 200 has a first control loop 202 and a second control loop 204 . The first control loop 202 has a first control unit 210 for controlling an excitation unit 230 . The first control unit 210 can control the MEMS through the excitation unit 230 or according to figure 1 The rotation rate sensor is along a first direction, for example along figure 1 Vibration in the x-direction. In addition, the excitation unit 230 can be as figure 1 As shown, there are one or more excitation electrodes 130 and electrodes 132 .

[0043] Furthermore, the first control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com